Marantz TT6200 User manual

Other Marantz Turntable manuals

Marantz

Marantz TT-15S1 User manual

Marantz

Marantz TT5005 User manual

Marantz

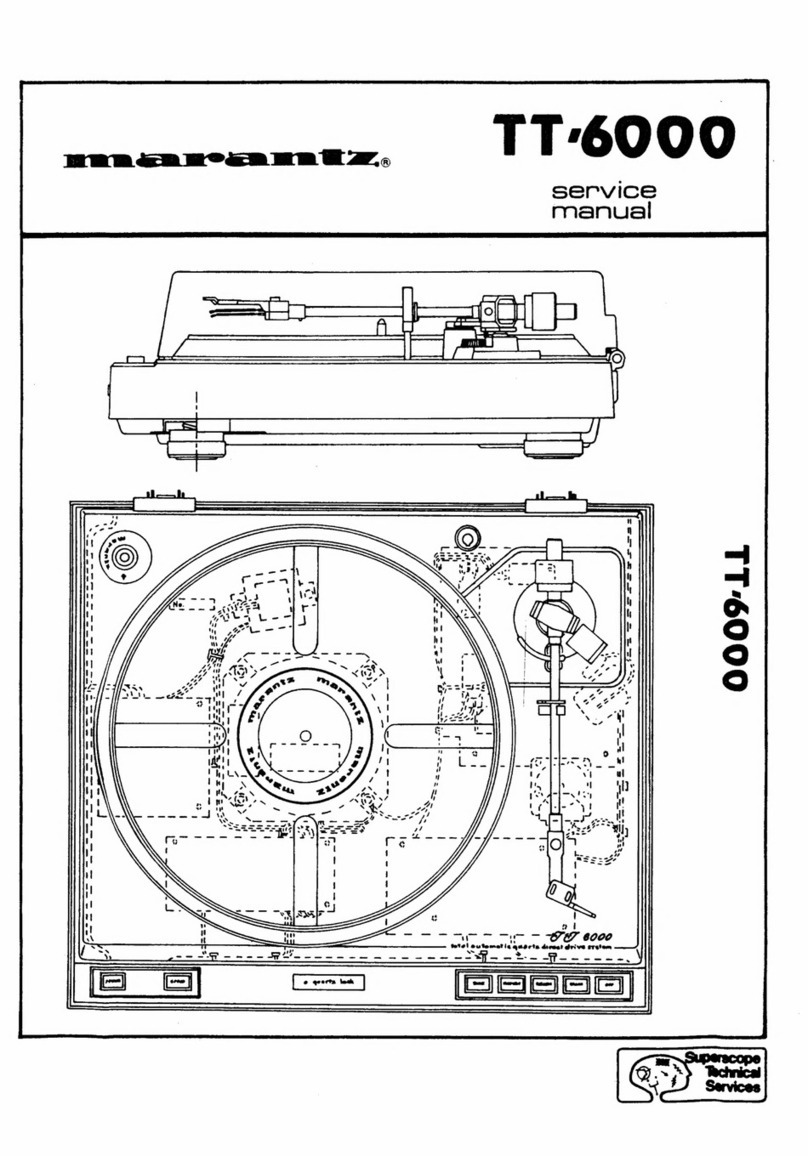

Marantz TT-6000 User manual

Marantz

Marantz TT-42 User manual

Marantz

Marantz TT-15S1 User manual

Marantz

Marantz TT-15S1 User manual

Marantz

Marantz TT-42 User manual

Marantz

Marantz JJ4000 Setup guide

Marantz

Marantz NA6005 User manual

Marantz

Marantz 6300 User manual

Marantz

Marantz TT8001 User manual

Marantz

Marantz TT-15S1 User manual

Marantz

Marantz TT-42 User manual

Marantz

Marantz TT5005 User manual

Marantz

Marantz TT-15S1 User manual

Marantz

Marantz BD7003 User manual

Marantz

Marantz TT-15S1 User manual

Marantz

Marantz TT-42 User manual

Marantz

Marantz TT-15S1 User manual

Marantz

Marantz TT5005 User manual