3 of 20

104 S. 8th Ave. Marshalltown, IA Phone 800-888-0127 / 641-753-0127 • Fax 800-477-6341 / 641-753-6341 www.MARSHALLTOWN.comWS# 2642

TABLE OF CONTENTS

INTRODUCTION ...........................................................................................................................................................................2

SAFETY PRECAUTIONS .............................................................................................................................................................3

SAFETY DECALS .........................................................................................................................................................................4

WARRANTY ..................................................................................................................................................................................4

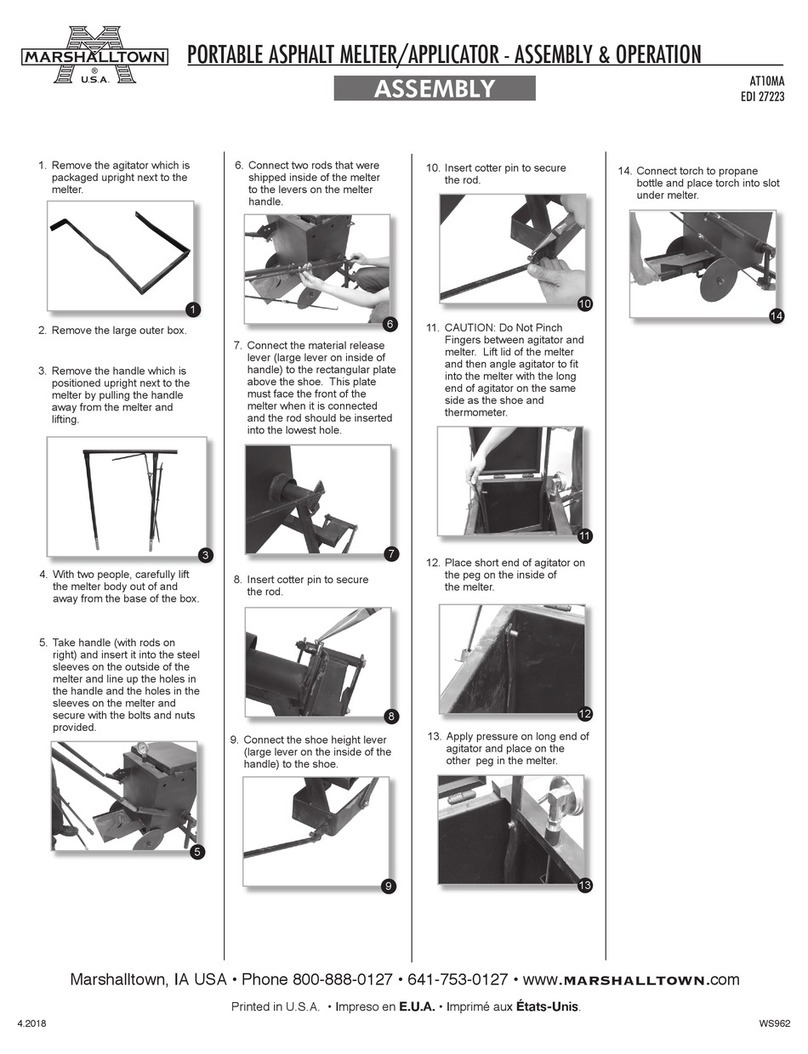

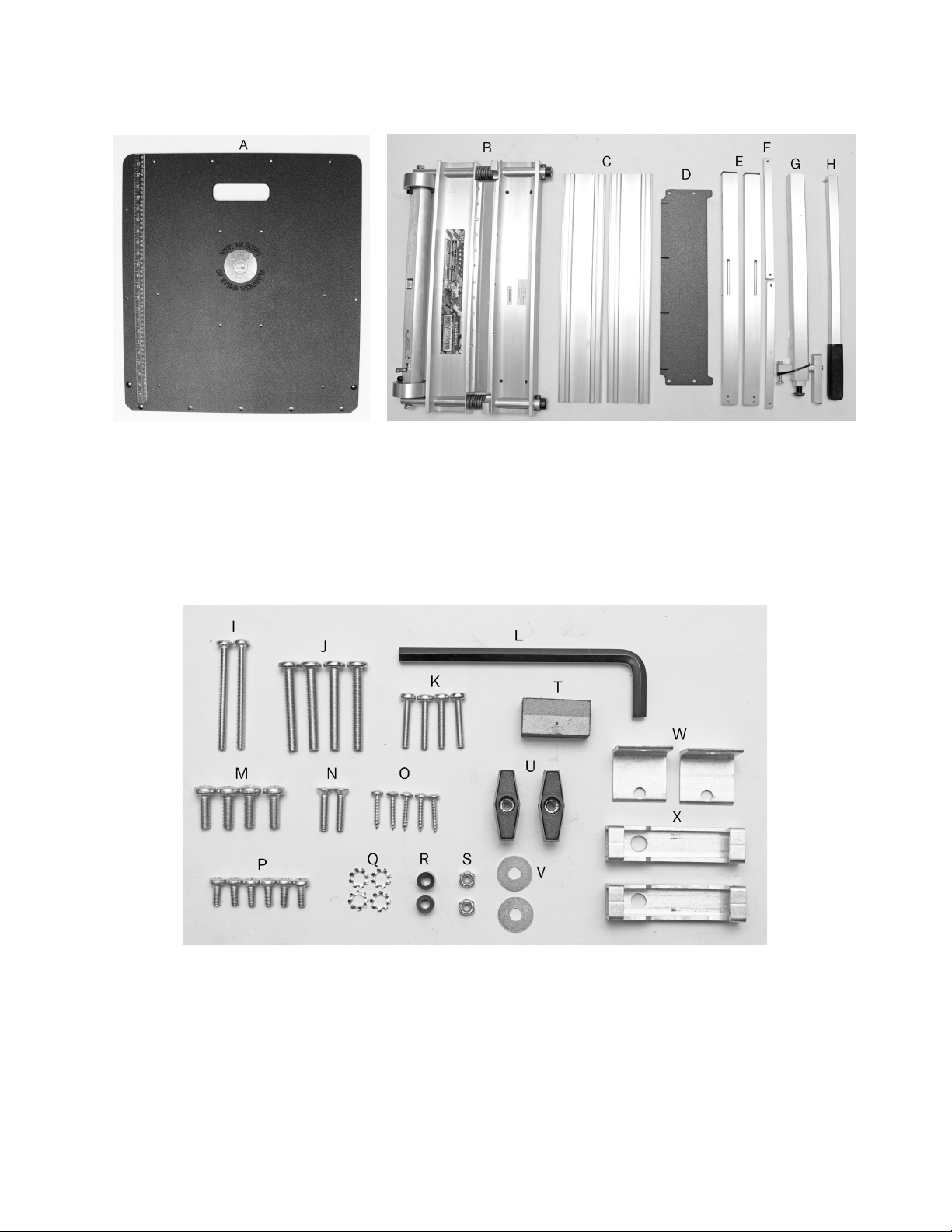

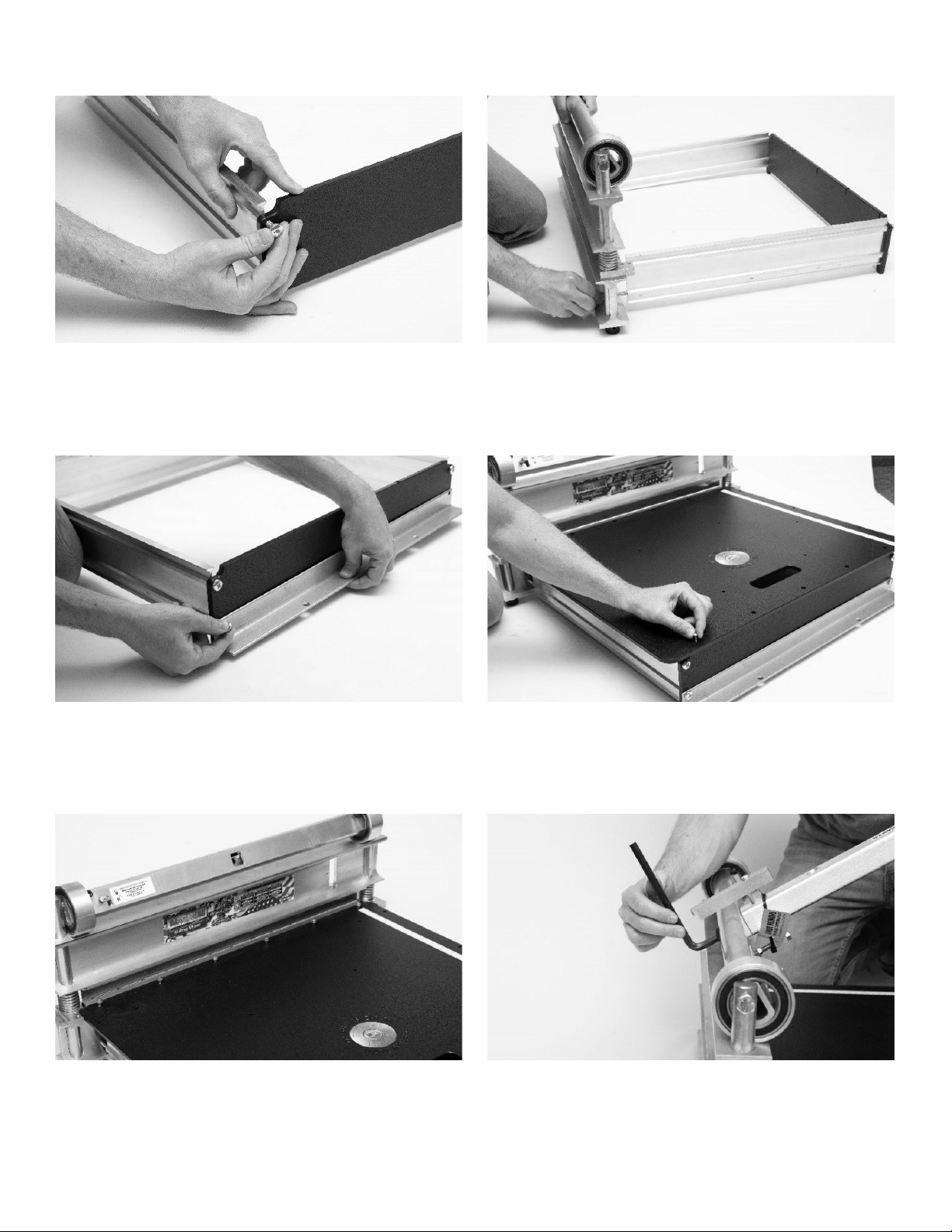

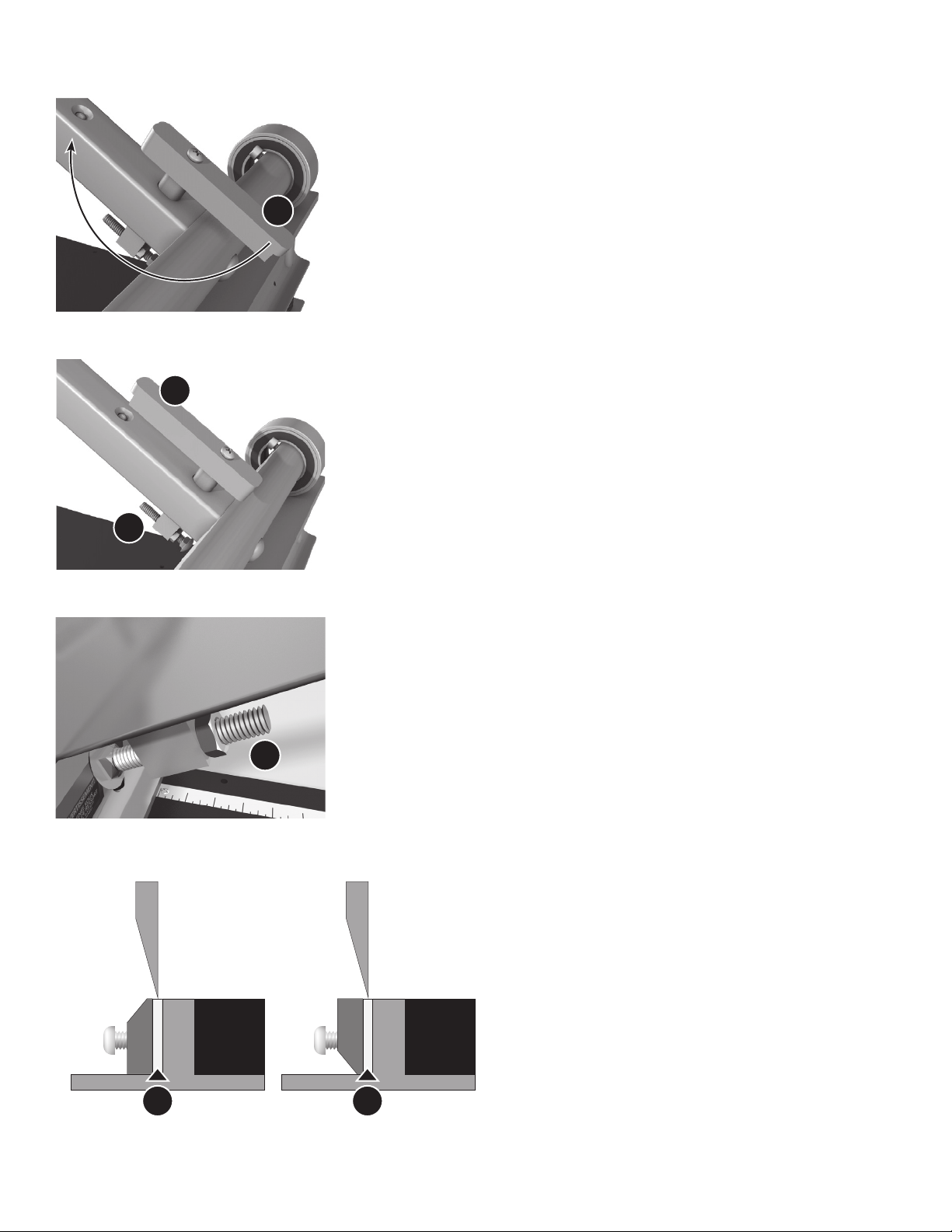

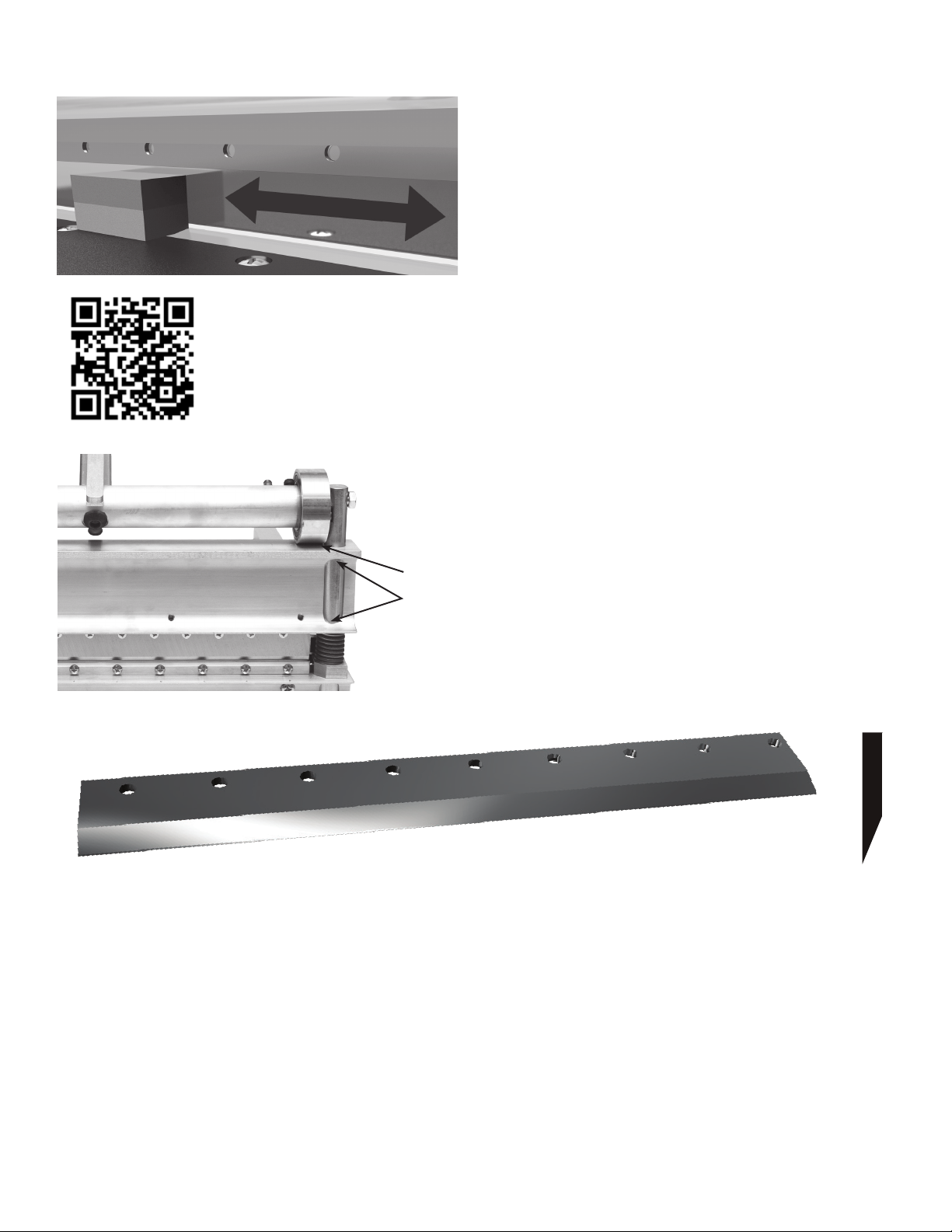

AS SEM BLY ................................................................................................................................................................................5-8

PRODUCT OPERATION...............................................................................................................................................................8

ADJUSTMENTS............................................................................................................................................................................9

MAINTENANCE ..........................................................................................................................................................................10

PARTS BREAKDOWN ..........................................................................................................................................................11-14

PARTS BREAKDOWN LIST (620-SID).............................................................................................................................. 15-16

PARTS BREAKDOWN LIST (MS20-0626) .......................................................................................................................16-17

TROUBLESHOOTING .......................................................................................................................................................... 18-19

SAFETY PRECAUTIONS

• DANGER or

WARNING safety signs are located near specific hazards.

• General precautions are listed on CAUTION safety signs.

This notation appears before warnings in the text. It means that the step that follows must be carried out to avoid the

possibility of personal injury or death. These warnings are intended to help the technician avoid any potential hazards

encountered in the normal service procedures. We strongly recommend that the reader takes advantage of the information

provided to prevent personal injury or injury to others.

THE FOLLOWING PRECAUTIONS ARE SUGGESTED TO HELP PREVENT ACCIDENTS. A CAREFUL OPERATOR IS THE

BEST OPERATOR. MOST ACCIDENTS CAN BE AVOIDED BY OBSERVING CERTAIN PRECAUTIONS. READ AND TAKE THE

FOLLOWING PRECAUTIONS BEFORE OPERATING THIS EQUIPMENT TO HELP PREVENT ACCIDENTS. EQUIPMENT SHOULD

BE OPERATED ONLY BY THOSE WHO ARE RESPONSIBLE AND INSTRUCTED TO DO SO.

CALIFORNIA PROPOSITION 65 WARNING: This product can expose you to chemicals known to the State of California

to cause cancer, birth defects, or other reproductive harm.

• Read all operating and maintenance instructions before operating or servicing the siding shear.

• A siding shear is only as safe as its operator. Give complete and undivided attention to the operation of the siding shear.

• Know how to stop the siding shear instantly.

NEVER operate the siding shear if any shear components have been removed.

• Always keep inexperienced and unauthorized people away from the siding shear.

• Keep the siding shear in good operational condition. Loose or damaged parts are dangerous.

• Avoid loose clothing that could get caught in moving parts.

Keep hands and feet away from moving parts.

• Keep all warning, caution, and safety instruction labels in good condition. Replace missing, damaged, or illegible labels.

• Clear the work area around the shear to prevent tripping or falling onto the shear.

• Operate on level ground to prevent the siding shear from flipping over.

• DO NOT OPERATE this siding shear under the influence of alcohol or while taking medication that impairs your reactions.

• Use only factory authorized parts for replacement.

• Wear safety glasses when operating the siding shear.

• Always use caution when replacing the shear blade.

• Only operate the shear with the approved materials. If extreme force is required to cut a material, it may result in personal

injury and/or damage to the siding shear.

• Wear proper protective clothing while operating siding shear, including eye, ear, and clothing.

• Handle all solvents and cleaning agents with care and follow manufacturer’s instructions on safety and disposal

.