2SKF LAGD 1000

Table of contents

EC Declaration of Conformity ..................................................................................4

Safety recommendations ..........................................................................................6

1. Description .....................................................................................................8

1.1 Application ...................................................................................................................... 8

1.2 Identification of parts .................................................................................................... 8

1.3 Designations ................................................................................................................... 9

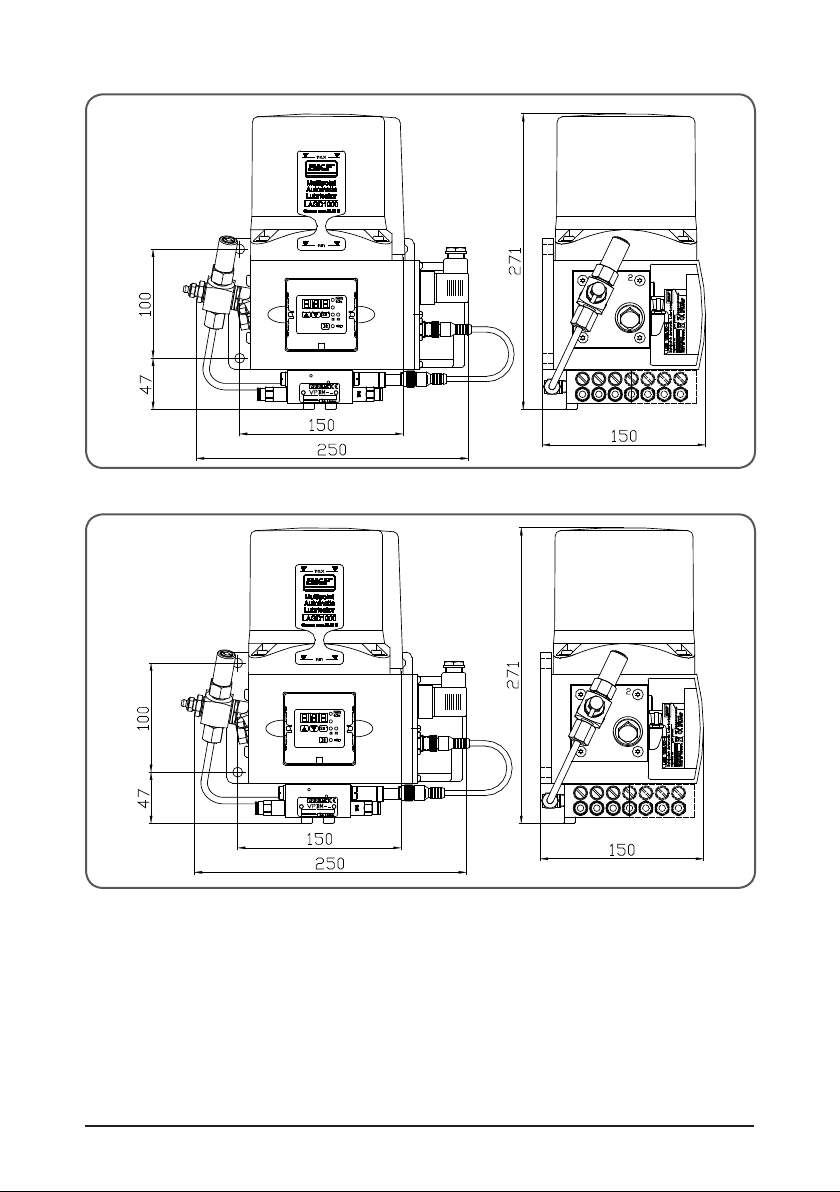

1.4 LAGD 1000 unit dimensions .....................................................................................10

2. Installation ...................................................................................................11

2.1 Preparation of lubrication points ...............................................................................11

2.2 Pump unit preparation................................................................................................12

2.3 Pump unit installation .................................................................................................13

2.4 Electrical connection ...................................................................................................14

2.4.1 Electrical specifications ..................................................................................14

2.4.2 LAGD 1000/DC ...............................................................................................14

2.4.3 LAGD 1000/AC ...............................................................................................15

2.5 Lubricant filling .............................................................................................................16

2.5.1 Suitability of greases .....................................................................................16

2.5.2 Compatibility of greases ................................................................................16

2.5.3 Initial filling of Lubricant ................................................................................16

2.5.4 Bleeding the system ......................................................................................17

2.5.5 Installation of lubrication pipes ....................................................................17

2.6 Level monitoring ..........................................................................................................19

2.6.1 Visual monitoring of level .............................................................................19

2.6.2 Level switch .....................................................................................................19

3. Selection of grease quantity for application ....................................................19

4. Operation of LAGD 1000/AC.. and LAGD 1000/DC.. units .................................20

4.1 LAGD 1000/AC.. & LAGD 1000/DC.. display and control unit ..............................20

4.1.1 Operation via push buttons ..........................................................................20

4.1.2 Three digit LED display .................................................................................21

4.2 Display mode for LAGD 1000/AC.. and LAGD 1000/DC .......................................22

4.2.1 Display of the operating values for LAGD 1000/AC.. & LAGD 1000/DC 22

4.3 Programming the LAGD 1000/AC.. and LAGD 1000/DC ......................................24

4.3.1 Changing the lubrication interval times ......................................................24

4.3.2 Programming sequence LAGD 1000/AC.. and LAGD 1000/DC ..............25

4.3.3 Changing the system monitoring.................................................................27

4.3.4 Changing the operating mode .....................................................................28

Original instructions