-6- -7-

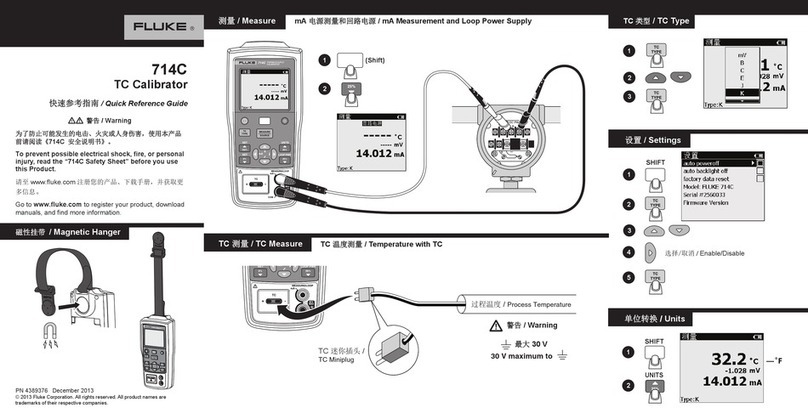

(A) Connect the mains lead into the tester by means of the

IEC socket provided.

(B) Connect the mains lead to a socket outlet supplied from

the RCD to be tested.

(C) Set the trip current selector switch to the current rating of

the RCD to be tested. Set the range switch to I and the

polarity switch to 0°. It is recommended that the test is

repeated with the switch in the 180°position.

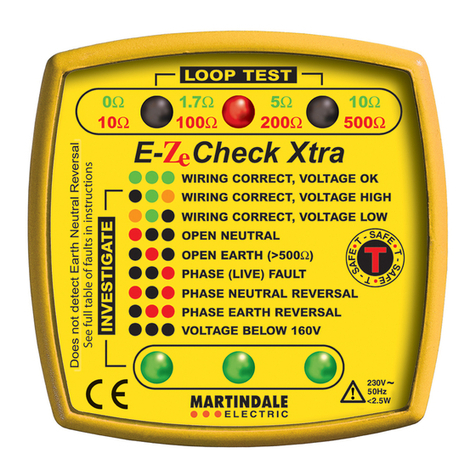

(D) Switch on the supply and check that both lamps on the

tester, marked P/N and P/E, have illuminated . If this is

the case then proceed with the test. If either or both of

the lamps are off, discontinue the test and correct the

wiring fault before proceeding. (An indication of

possible wiring faults can be found on page 9).

(E) To proceed with the test the READY symbol must be

displayed. Press and hold the test switch and the reading

displayed will be the time taken in mSec for the RCD to

trip.

(F) Should the RCD under test fail to trip within 2000

milliseconds the OVER RANGE symbol on the tester

will indicate that the unit has failed. Where the RCD

under test trips within 500 or 2000 milliseconds, the trip

time will be displayed on the LCD. With a fault current

flowing equivalent to 100% of the rated tripping current of

the RCD, the device will open in less than 200ms.

(G) The RCD should also be tested to ensure that it can

withstand half the rated trip current without tripping. Set

the range switch to ½ then test as before. The RCD under

test should not trip and the OVERRANGE symbol will

indicate a successful test after 2000 milliseconds have

elapsed.

(H) If the READY symbol is not visible on the LCD, the

thermal time delay is operating to protect the instrument

against overheating, there is voltage greater than 50Vr.m.s.

between the earth and neutral terminals or the instrument

has a fault. If ~ symbol is displayed, then there is a

voltage greater than 50 Vrms between the earth and neutral

terminals. If the READY symbol appears after a few

minutes, then the tester has overheated, and testing can be

resumed. If not,check the wiring lamps to see if they

indicate a wiring fault which could cause a voltage

between the phase and neutral terminals.

(I) Where RCDs with a current rating not exceeding 30mA

have been installed, it is necessary for the RCD to trip

within 40 milliseconds when 150mA is applied. Set the

range switch to FAST for 150mA trip current and proceed

as before.

NOTE: Setting the range switch to FAST over-rides the trip current

selector switch.

(J) The time for the full trip current test is set to 2000mS or

500mS by means of a switch on the front edge of the tester

beside the mains inlet. A multi-purpose mains lead is

available for testing RCDs where the final sub-circuits

are not connected to socket outlets.

-6- -7-

(A) Connect the mains lead into the tester by means of the

IEC socket provided.

(B) Connect the mains lead to a socket outlet supplied from

the RCD to be tested.

(C) Set the trip current selector switch to the current rating of

the RCD to be tested. Set the range switch to I and the

polarity switch to 0°. It is recommended that the test is

repeated with the switch in the 180°position.

(D) Switch on the supply and check that both lamps on the

tester, marked P/N and P/E, have illuminated . If this is

the case then proceed with the test. If either or both of

the lamps are off, discontinue the test and correct the

wiring fault before proceeding. (An indication of

possible wiring faults can be found on page 9).

(E) To proceed with the test the READY symbol must be

displayed. Press and hold the test switch and the reading

displayed will be the time taken in mSec for the RCD to

trip.

(F) Should the RCD under test fail to trip within 2000

milliseconds the OVER RANGE symbol on the tester

will indicate that the unit has failed. Where the RCD

under test trips within 500 or 2000 milliseconds, the trip

time will be displayed on the LCD. With a fault current

flowing equivalent to 100% of the rated tripping current of

the RCD, the device will open in less than 200ms.

(G) The RCD should also be tested to ensure that it can

withstand half the rated trip current without tripping. Set

the range switch to ½ then test as before. The RCD under

test should not trip and the OVERRANGE symbol will

indicate a successful test after 2000 milliseconds have

elapsed.

(H) If the READY symbol is not visible on the LCD, the

thermal time delay is operating to protect the instrument

against overheating, there is voltage greater than 50Vr.m.s.

between the earth and neutral terminals or the instrument

has a fault. If ~ symbol is displayed, then there is a

voltage greater than 50 Vrms between the earth and neutral

terminals. If the READY symbol appears after a few

minutes, then the tester has overheated, and testing can be

resumed. If not,check the wiring lamps to see if they

indicate a wiring fault which could cause a voltage

between the phase and neutral terminals.

(I) Where RCDs with a current rating not exceeding 30mA

have been installed, it is necessary for the RCD to trip

within 40 milliseconds when 150mA is applied. Set the

range switch to FAST for 150mA trip current and proceed

as before.

NOTE: Setting the range switch to FAST over-rides the trip current

selector switch.

(J) The time for the full trip current test is set to 2000mS or

500mS by means of a switch on the front edge of the tester

beside the mains inlet. A multi-purpose mains lead is

available for testing RCDs where the final sub-circuits

are not connected to socket outlets.