15 16

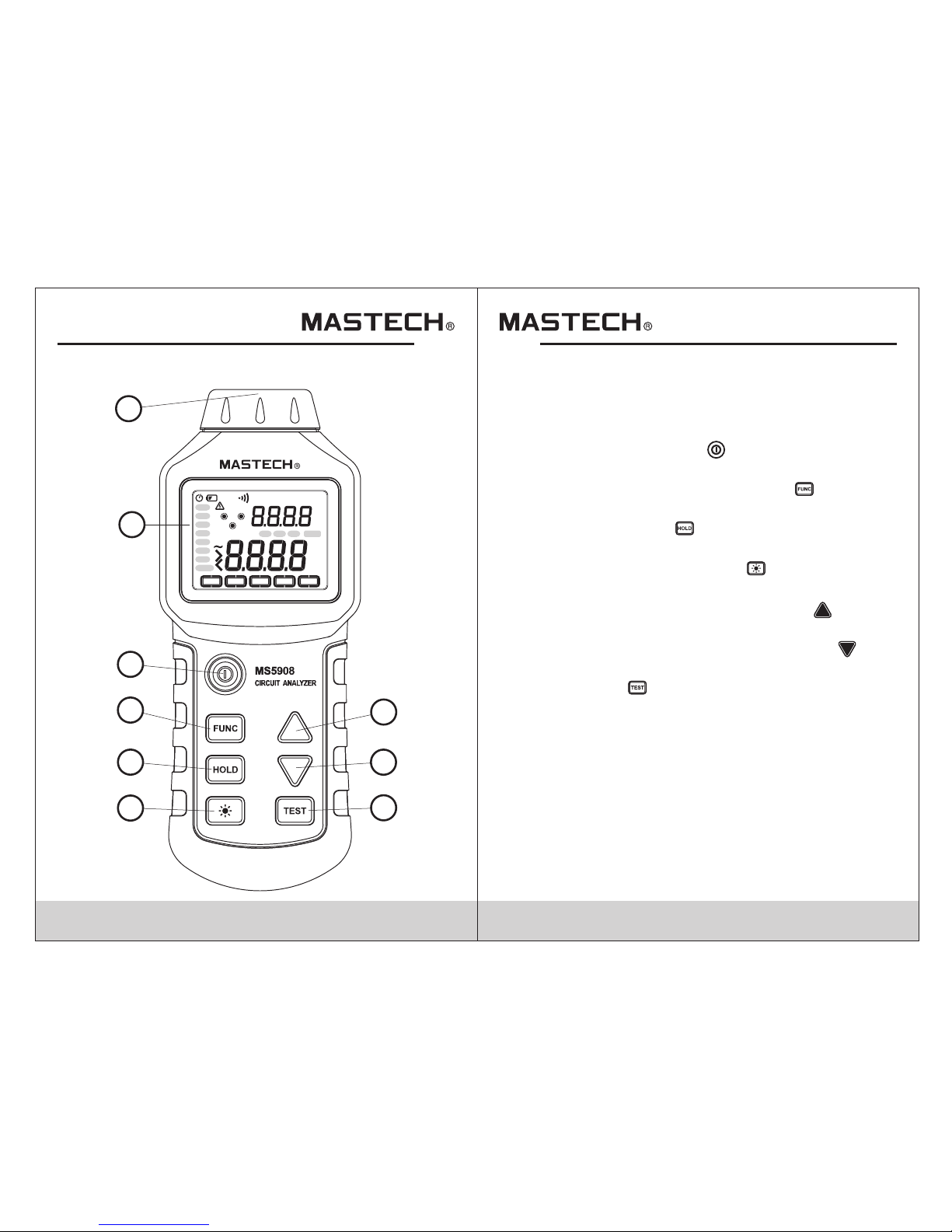

Voltage drop (V ) measurement

Dummy load shall be used in the circuit to

measure the load phase voltage and then calculate

the voltage drop. The voltage drop and load phase

voltage will be displayed when the load reaches

12A, 15A and 20A.

In terms of qualified circuit, when measurement

is made in the most remote socket from the

switchboard, the voltage drop shall be less than 5%.

During the measurement of the remaining sockets

of the same area, the farthest socket from the

switchboard shall be measured first and then other

measurements shall be made from the distant to

the near. The reading of the voltage drop shall be

shown on the downward trend.

If the voltage drop exceeds 5% and no obvious

drop of reading is found during the measurement

made near the switchboard, it indicates that the

first connection point goes wrong. In this case,

perform a visual inspection of the wire connection

among the first connection point, equipment and

switchboard and the connection of breaker

(air-break switch). Usually, a high impedance point

generates heat. To locate this problem, infrared

radiation thermometer can be used. In addition, we

can directly measure the voltage on both sides of

the breaker (air-break switch) to locate the point of

failure.

d If the voltage drop exceeds 5%, and during the

measurement made near the switchboard, the

reading drops constantly and no obvious change

is found between the two sockets, it indicates that

the lead wire diameter is too small compared with

the transmission distance, the transmission

distance is too long or the circuit is overloaded.

Under such circumstances, check the cable to see

if the lead wire diameter complies with the required

standard, and measure the lead wire current to see

if it is overloaded.

If the voltage drop exceeds 5% and there is an

obvious change of voltage drop reading between

the two sockets, it indicates that a high impedance

point exists between the two sockets. Usually,

problems are found at the contact, such as poor

connection, loose connector, or socket problem.