WEAR WORK GLOVES (RUBBER COATED PREFERRED)

FOR GRIPPINGTHE ADAPTER. This tool is designed to

be used in drills chucks to set blind rivets up to 1/4" in

aluminum, steel and copper, and up to 7/32" in stainless

steel. No use esta herramienta fuera de la intención de

su diseño. Nunca modifique la herramienta para ningún

otro propósito o uso.

Estudie, entienda y siga todas las instrucciones

que se proveen con este producto. Lea las

instrucciones detenidamente antes de instalar,

operar, dar servicio o reparar esta herramienta.

Guarde estas instrucciones en un lugar seguro

y accesible.

APLICACIÓN DE LA HERRAMIENTA

HECHO en China

para Matco especificaciones

El fabricante garantiza este producto al usuario original contra defectos

de materiales o de mano de obra durante un periodo de un año a partir

de la fecha de compra.

El fabricante se reserva el derecho a determinar si una pieza o piezas

fallaron debido a material defectuoso, mano de obra, o por otras

causas.

Esta garantía no cubre fallas causadas por accidentes, alteraciones o

uso indebido.

El fabricante, a su entera discreción, reparará o reemplazará los

productos cubiertos por esta garantía sin costo alguno. Las

reparaciones o reemplazos de productos cubiertos por esta garantía

quedan garantizados durante el resto del periodo original de garantía.

El fabricante o sus representantes autorizados de servicio deben llevar

a cabo todas las reparaciones de garantía.Toda reparación hecha al

producto por representantes de servicio no autorizados invalida la

presente garantía. Los derechos que ampara esta garantía están

limitados al usuario original y no se pueden transferir a dueños

posteriores.

Esta garantía reemplaza a todas las demás garantías expresas o

implícitas, incluyendo garantías de comercialización e idoneidad para

un propósito particular. Algunos estados no permiten la exclusión o

limitaciones de daños incidentales o imprevistos, de manera que las

limitaciones mencionadas anteriormente pueden no ser aplicables en

su caso.

GARANTÍA LIMITADA DE UN AÑO

ADVERTENCIA

• El uso de este producto puede exponerlo a productos

químicos que incluyen etilenglicol, vapores de gasolina y

gases de escape del motor, que en el estado de California

son causantes de cáncer, defectos de nacimiento o daños

reproductivos. Para obtener más información, visite

www.P65Warnings.ca.gov . Siempre use equipo de

seguridad aprobado por ANSI, gafas de seguridad y ropa

cuando use este producto. Estudie, comprenda y siga

todas las instrucciones proporcionadas con este

producto. Si no lee y sigue todas las advertencias e

instrucciones de funcionamiento puede ocasionar daños

y lesiones graves o la muerte.

• Siempre use guantes del tipo aprobado por la ANSI para

trabajar con esta herramienta. (tanto usuarios como

espectadores).

• Nunca utilice esta herramienta para cualquier otra cosa

que no sean las aplicaciones para lo que fue diseñada.

• Sólo utilice los accesorios diseñados para esta

herramienta.

• No modifique o altere esta herramienta de ninguna

manera.

• El funcionamiento y/o mantenimiento inadecuado de la

herramienta, la modificación, o la utilización de la

herramienta con accesorios inadecuados podrían causar

lesiones graves o la muerte.

• Siempre usar los correctos accesorios para el trabajo que

Ud. está realizando.

• Trabaje siempre en un área limpia, segura, bien iluminada,

organizada y equipada adecuadamente.

INFORMACIÓN DEL PRODUCTO:

DESEMPACADO

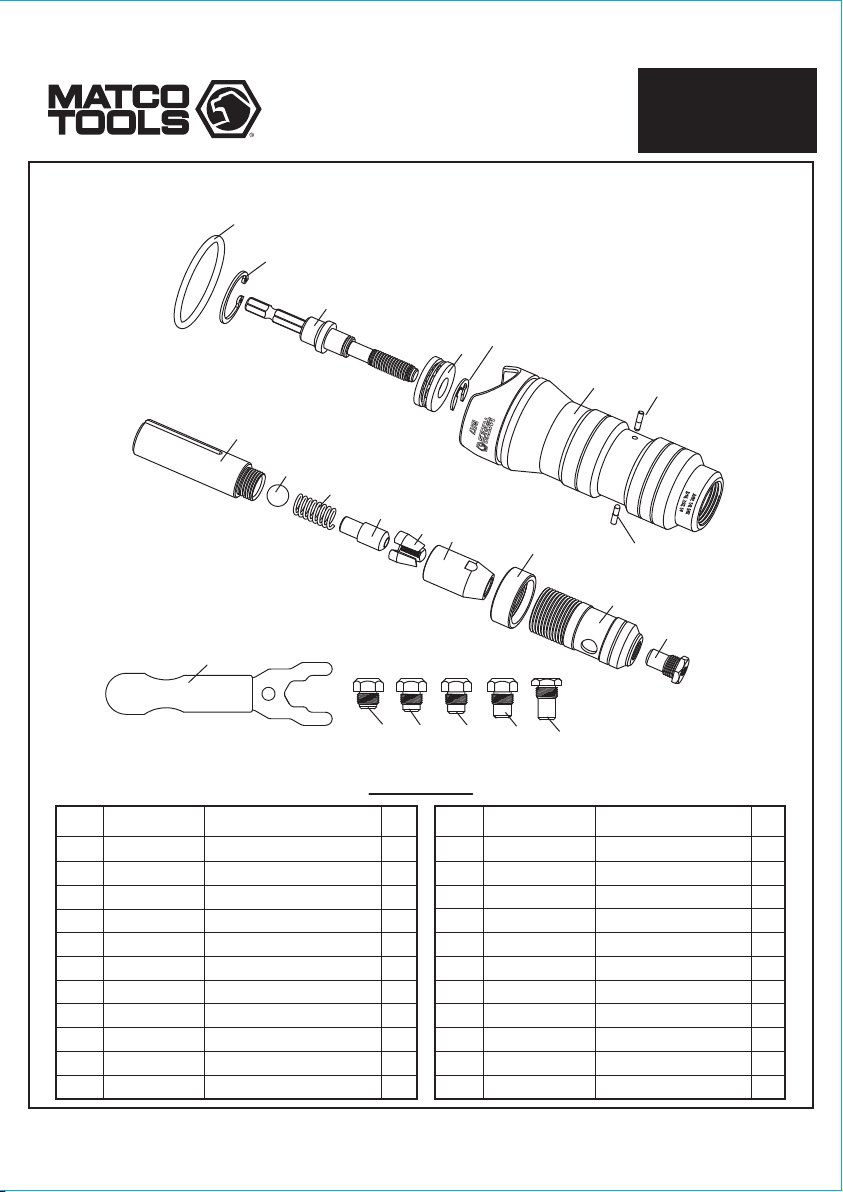

Cuando desempaque el producto, revise el diagrama y la

lista de piezas en página 4 para verificar que se hayan

enviado todas las piezas. De perder piezas o tener piezas

dañadas, favor llamar a su distribuidor inmediatamente.

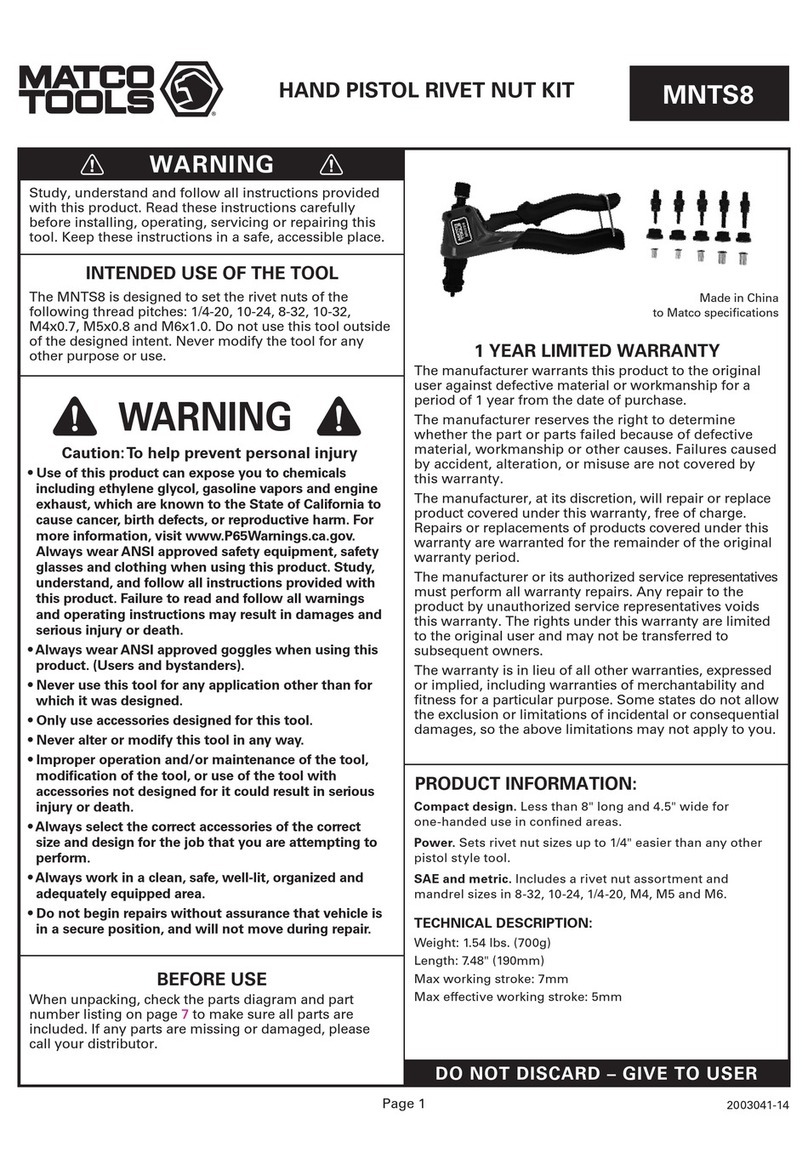

• Adaptability. Easily convert your cordless,

pneumatic or corded drill into a power pop

riveter.

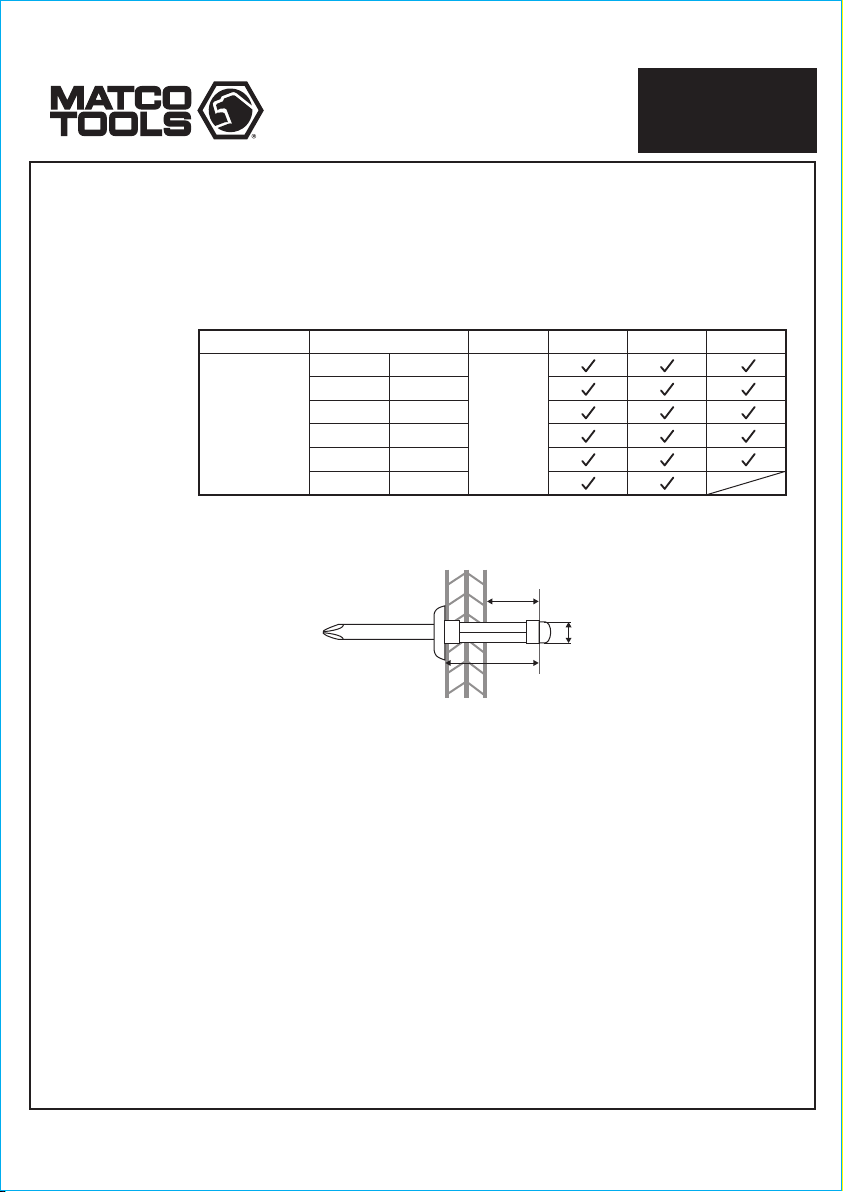

• Versatility. Includes nose pieces for 3/32",

1/8", 5/32", 3/16", 7/32" and 1/4" for steel,

aluminum and copper, or up to 7/32" in

stainless.

• Durability. Features large shielded bearings

and billet aluminum machined body.

• Works on up to 8-6" rivet bodies, with a

maximum stroke of 0.7".

ADVERTENCIA

BLIND RIVET

ADAPTER KIT

BR7

NO LO DESCARTE O DESECHE, ENTREGESELO AL USUARIO

Página 1 1802031-14