Matco warrants its air tools for a period of 1 year to the consumer. We will repair any air tool covered

under this warranty which proves to be defective in material or workmanship during the warranty period.

In order to have your tool repaired, return the tool to any Warranty Center, freight prepaid. Please include

a copy of your proof of purchase and a brief description of the problem. The tool will be inspected and

if any part or parts are found to be de fec tive in ma te ri al or work man ship, they will be repaired free of

charge and the re paired tool will be re turned to you freight pre paid.

This warranty gives you specific rights. You may also have other rights which vary from state to state.

The foregoing obligation is Matco's sole liability under this or any implied warranty and under no cir cum-

stanc es shall Matco be liable for any incidental or consequential damages.

Note: Some states do not allow the exclusion or limitation of incidental or consequential damages so the

above limitation or exclusion may not apply to you.

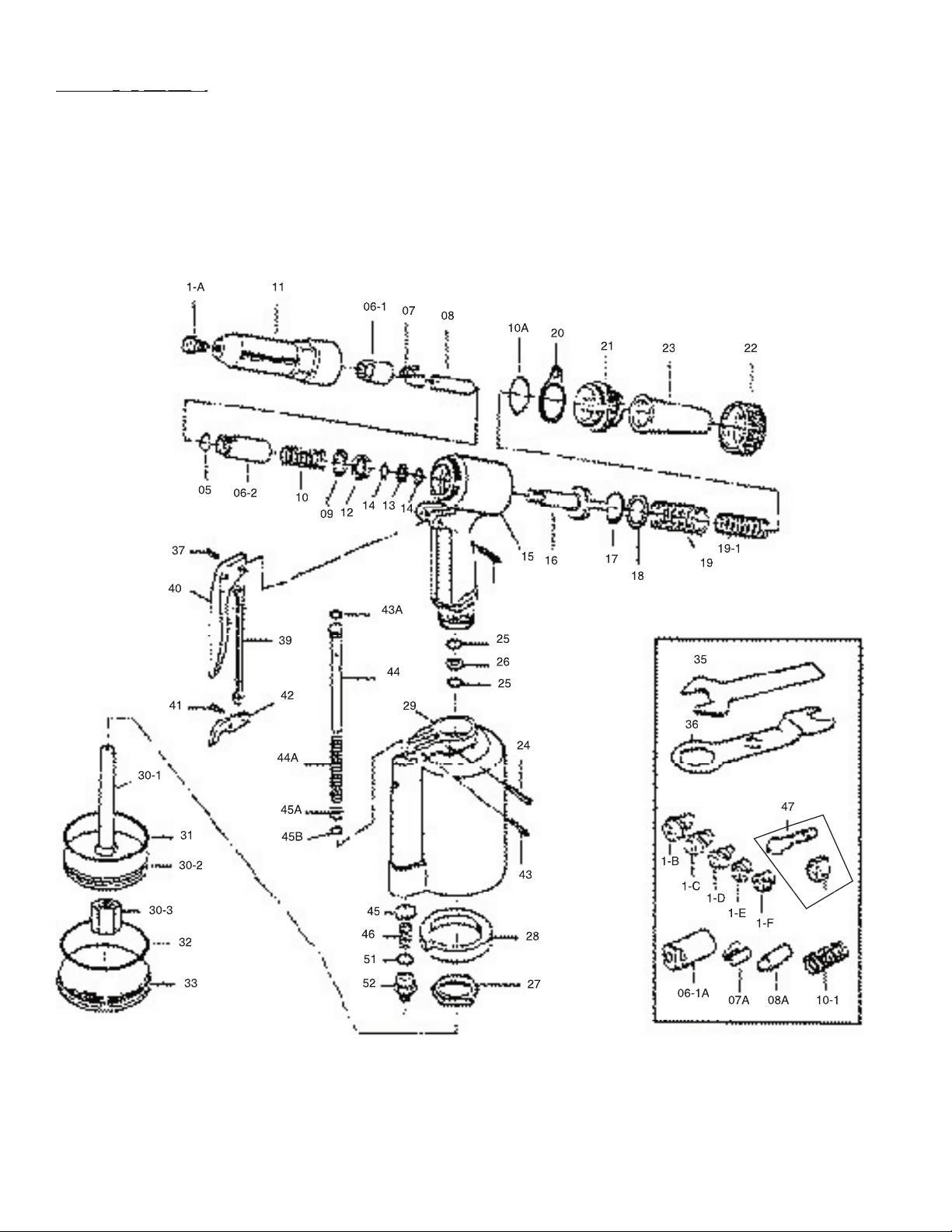

Ref. # Item # DESCRIPTION

1A 38401A 5/32" Nosepiece (optional)

1B 38401B 1/8" Nosepiece (optional)

1C 38401C 3/32" Nosepiece (optional)

1D 38401D 1/4" Nosepiece (standard)

1E 38401E 7/32" Nosepiece (optional)

1F 38401F 3/16" Nosepiece (optional)

05 38405 Jaw Case End Tart O-Ring

06-1 38406-1 Jaw Case Front Tart (3/32", 1/8",

06-2 38406-2 Jaw Case End Tart

06-1A 38406-1A Jaw Case Front Tart (1/4", 7/32",

08 38408 Jaw Pusher (3/32", 1/8", 5/32")

08A 38408A Jaw Pusher (1/4", 7/32", 3/16")

09 38309 Case Washer Ring

10 38410 Jaw Pusher Spring (5/32")

10-1 38410-1 Jaw Pusher Spring (1/4")

10A 38410A Frame Cap O-Ring

17 38417 Oil Piston O-Ring

19 38419 Return Spring (Old)

19-1 38419-1 Return Spring (Small)

Ref. # Item # DESCRIPTION

24 38424 Setting Screw Pin

30-1 38430-1 Air Piston Stem

30-3 38430-3 Air Piston Lock Nut

31 38431 Air Piston O-Ring

43A 38443A Valve Pusher O-Ring

46 38346 Valve Spring (Bottom)

47 38447 Inlet Bushing and Nut

51 38351 Valve Cap O-Ring

Ref. # Item # DESCRIPTION

1A 38401A 5/32" Nosepiece (optional)

1B 38401B 1/8" Nosepiece (optional)

1C 38401C 3/32" Nosepiece (optional)

1D 38401D 1/4" Nosepiece (standard)

1E 38401E 7/32" Nosepiece (optional)

1F 38401F 3/16" Nosepiece (optional)

05 38405 Jaw Case End Tart O-Ring

06-1 38406-1 Jaw Case Front Tart (3/32", 1/8",

06-2 38406-2 Jaw Case End Tart

06-1A 38406-1A Jaw Case Front Tart (1/4", 7/32",

08 38408 Jaw Pusher (3/32", 1/8", 5/32")

08A 38408A Jaw Pusher (1/4", 7/32", 3/16")

09 38309 Case Washer Ring

10 38410 Jaw Pusher Spring (5/32")

10-1 38410-1 Jaw Pusher Spring (1/4")

10A 38410A Frame Cap O-Ring

17 38417 Oil Piston O-Ring

19 38419 Return Spring (Old)

19-1 38419-1 Return Spring (Small)

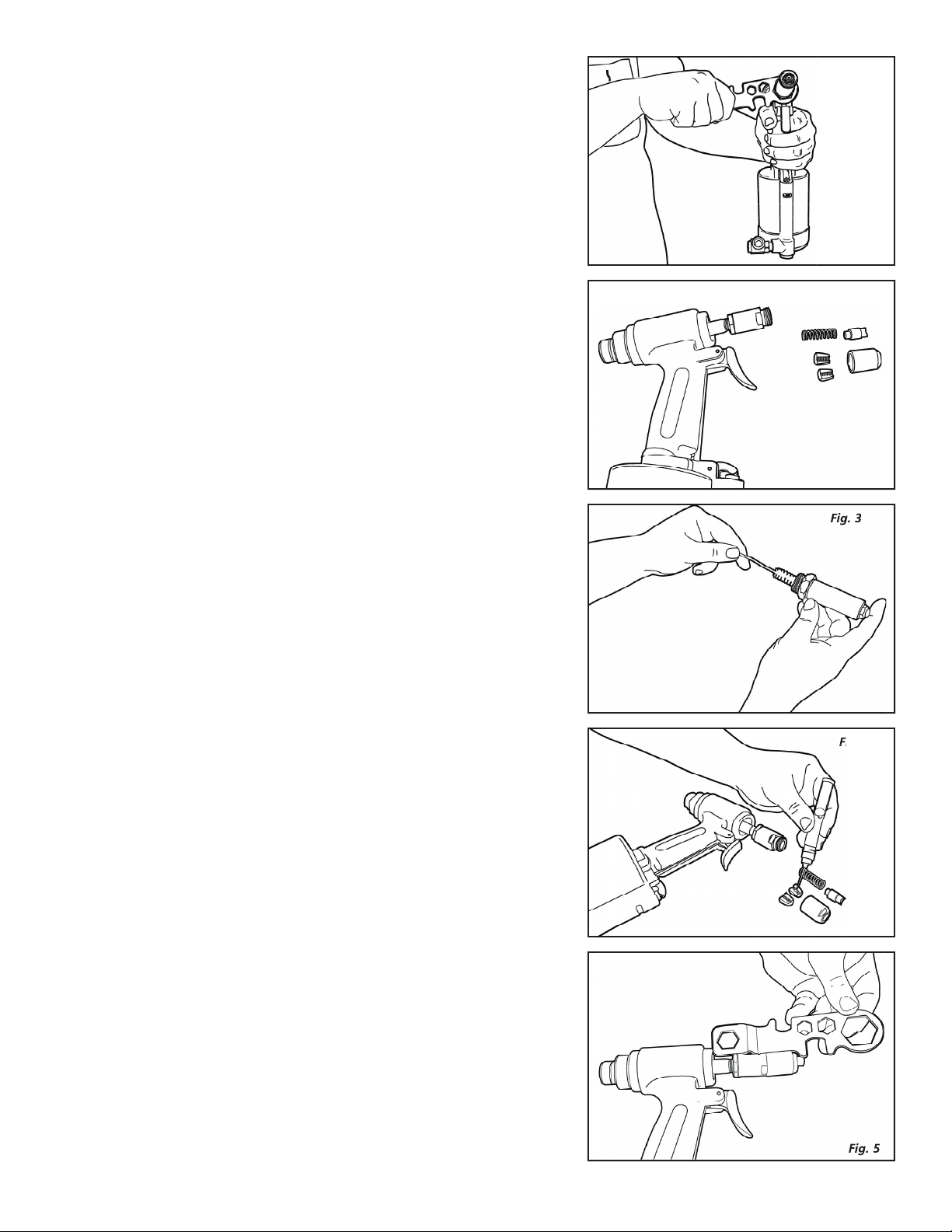

NOTE: in changing nosepieces, be sure to install the correct jaw case front tart, jaws, jaw pusher, and