Content

Page 2

Table of contents

1.1 About this operating manual........................................................................................3

2Safety.........................................................................................................................4

2.1 Intended use...............................................................................................................4

2.2 Qualification of personnel............................................................................................4

2.3 General safety instructions..........................................................................................4

2.4 Special safety instructions...........................................................................................5

3Installation.................................................................................................................6

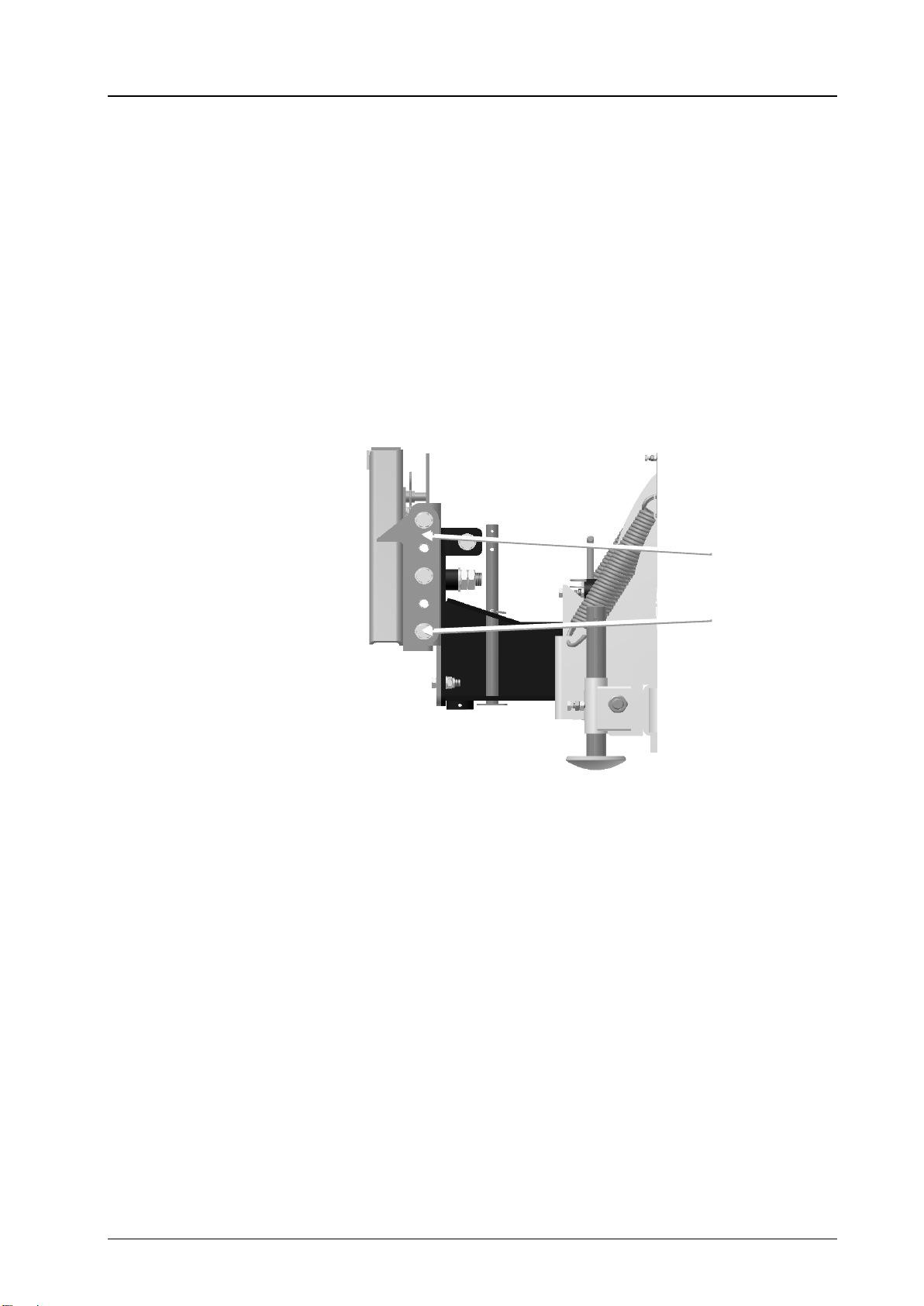

3.1 Preparations on the snow blade..................................................................................6

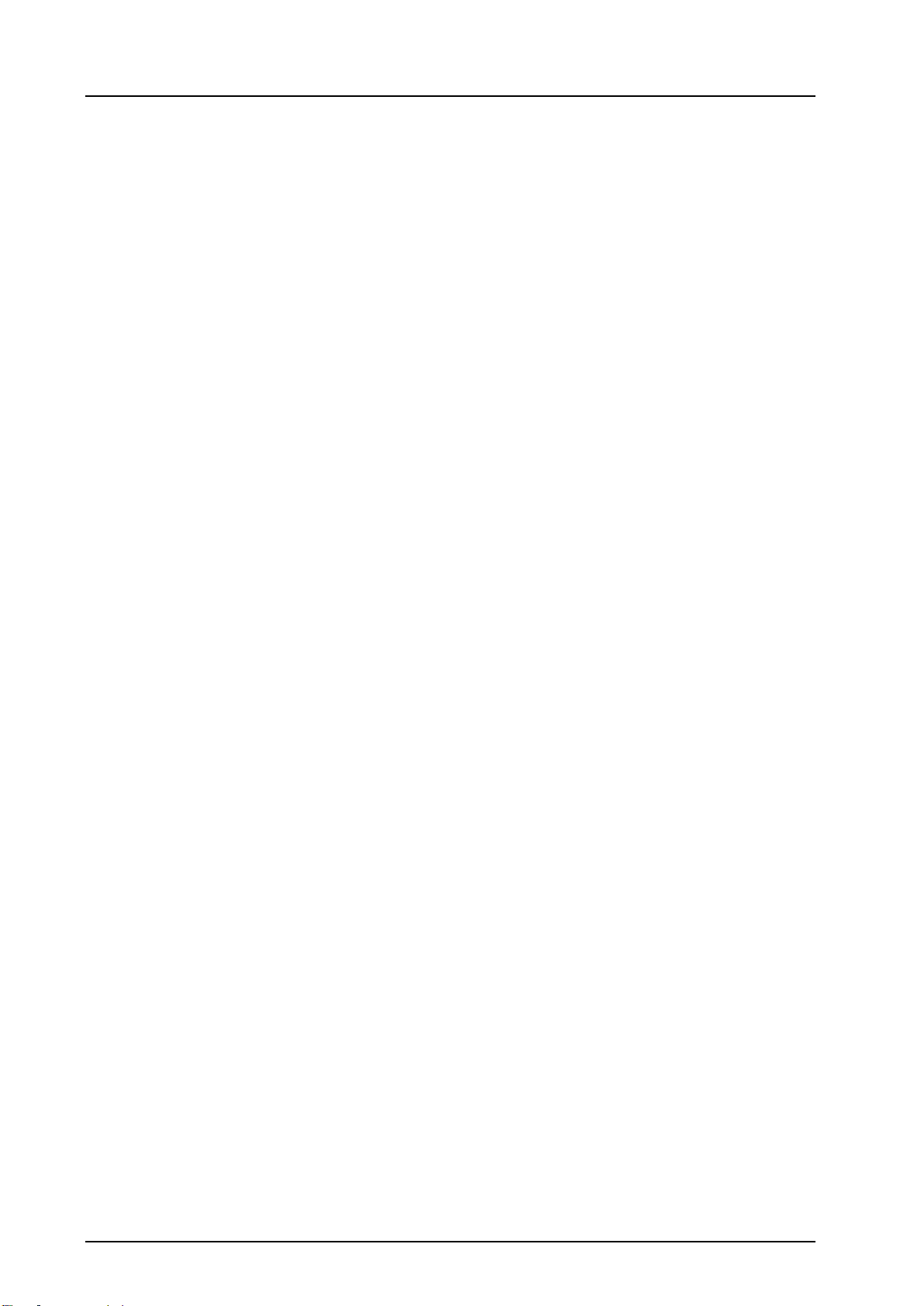

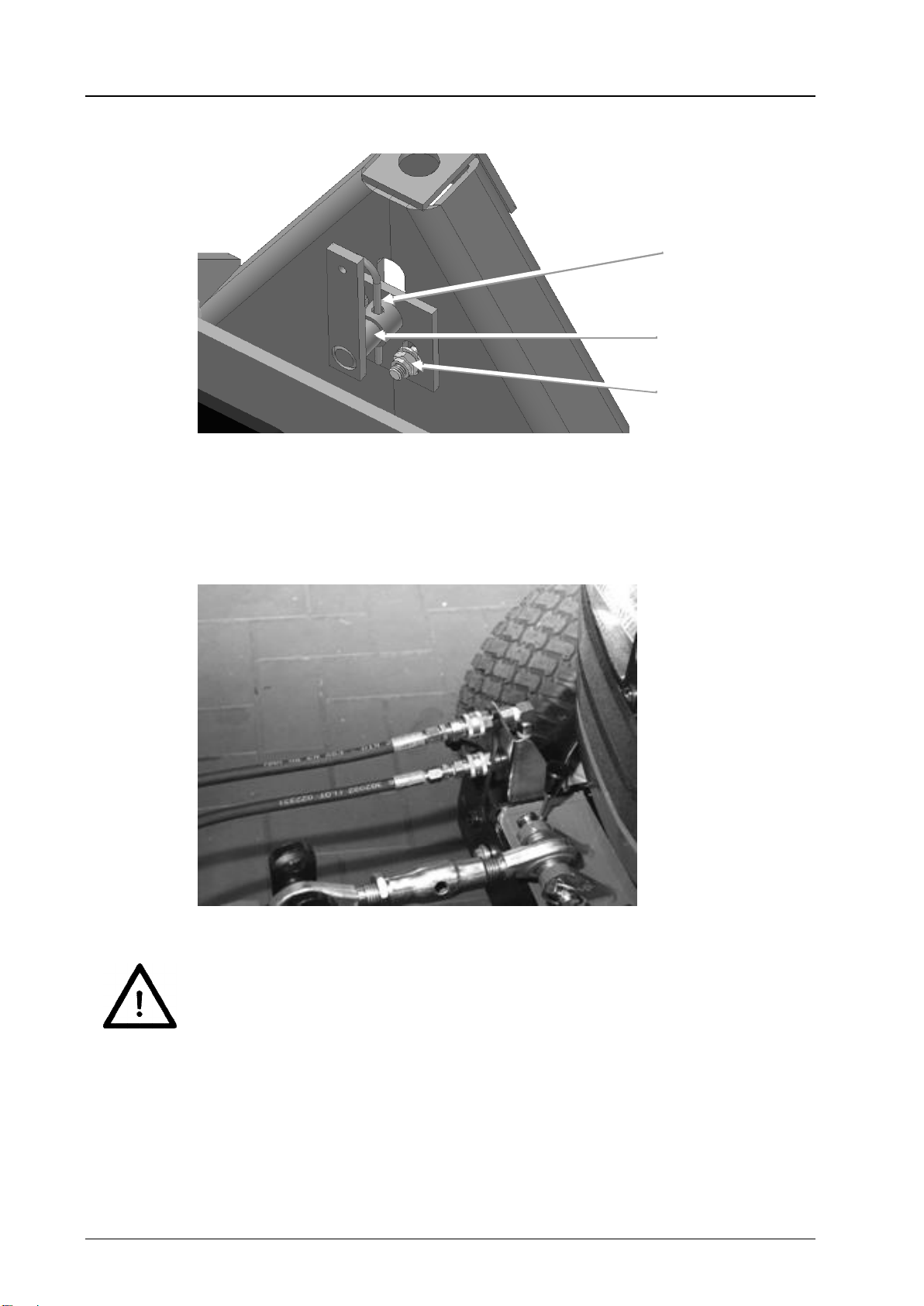

3.2 Installation of pressure contol valve ............................................................................8

3.3 Attaching the snow blade on the tractor ......................................................................9

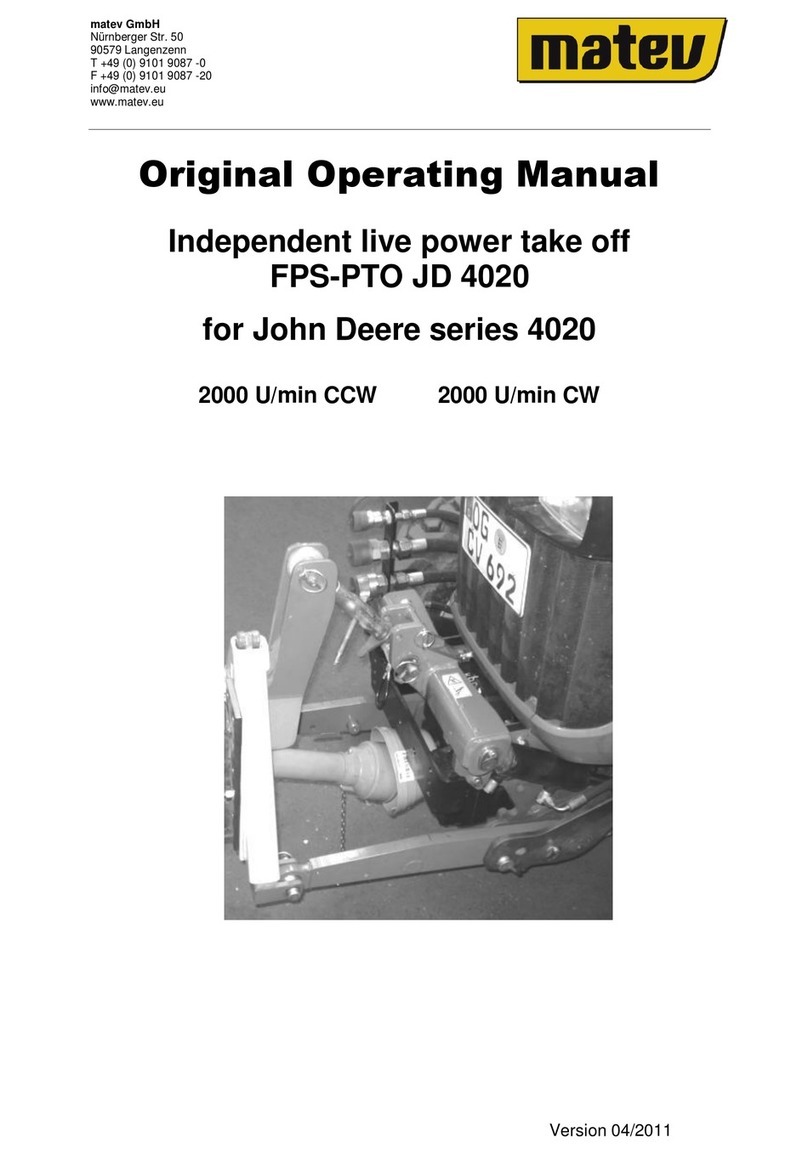

3.4 Adjustments on the snow blade ................................................................................13

4Operation and fault correction...............................................................................16

4.1 Operation..................................................................................................................16

4.2 Faults........................................................................................................................16

4.3 Contact .....................................................................................................................17

5Service.....................................................................................................................18

6Disposal...................................................................................................................20

7Guarantee................................................................................................................20

8Technical data and accessories.............................................................................20

8.1 Technical data...........................................................................................................20

9List of illustrations..................................................................................................21

10 EC Declaration of Conformity ................................................................................22