Matrix A30 User manual

Other Matrix Fitness Equipment manuals

Matrix

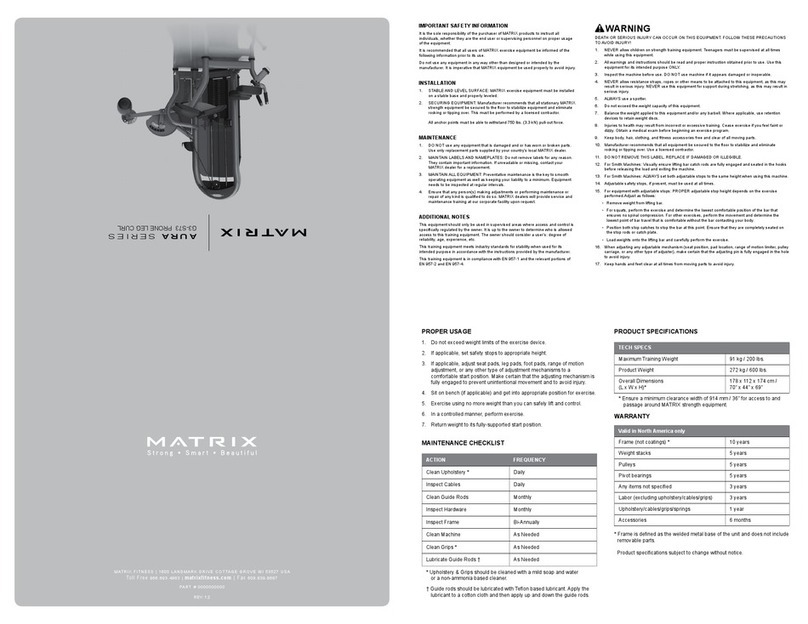

Matrix AURA Series User manual

Matrix

Matrix C7XE-05 User manual

Matrix

Matrix MAGNUM SERIES User manual

Matrix

Matrix ClimbMill C50-F User manual

Matrix

Matrix MAGNUM SERIES User manual

Matrix

Matrix A30 User manual

Matrix

Matrix VS-S13 User manual

Matrix

Matrix MX-S21 User manual

Matrix

Matrix MAGNUM SERIES User manual

Matrix

Matrix CONNEXUS STEP+ User manual

Matrix

Matrix IC3 User manual

Matrix

Matrix LIFESTYLE CLIMBMILL User manual

Matrix

Matrix ULTRA Series User manual

Matrix

Matrix MAGNUM MG-DP921 User manual

Matrix

Matrix AURA Series User manual

Matrix

Matrix AURA Series User manual

Matrix

Matrix G3 Seat Post Revision User manual

Matrix

Matrix CONNEXUS COMPACT GFTCOR User manual

Matrix

Matrix ROWER-02 User manual

Matrix

Matrix MAGNUM SERIES User manual