2

2.1 READ AND SAVE THESE INSTRUCTIONS

CHAPTER 2: IMPORTANT SAFETY INSTRUCTIONS

•If you experience any kind of pain, including but not limited to chest

pains, nausea, dizziness, or shortness of breath, stop exercising

immediately and consult your physician before continuing.

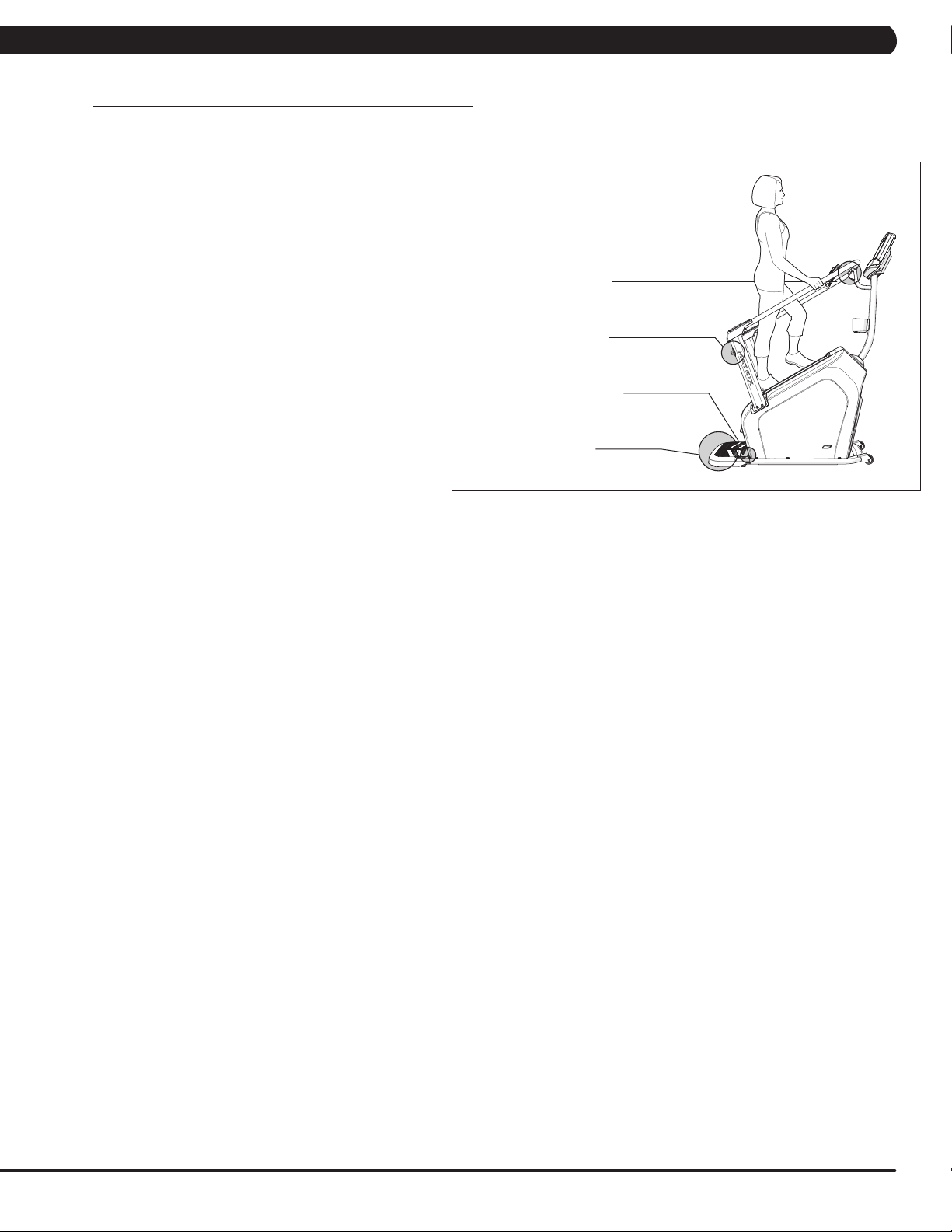

•When exercising, always maintain a comfortable pace.

•Do not wear clothes that might catch on any part of the equipment.

•Always wear athletic shoes while using this equipment.

•Do not jump on the equipment.

•At no time should more than one person be

on equipment while in operation.

•This equipment should not be used by persons weighing more

than specified on this card. Failure to comply will void the warranty.

•This equipment should not be used by persons weighing less

than specified on this card. Failure to comply may cause injury.

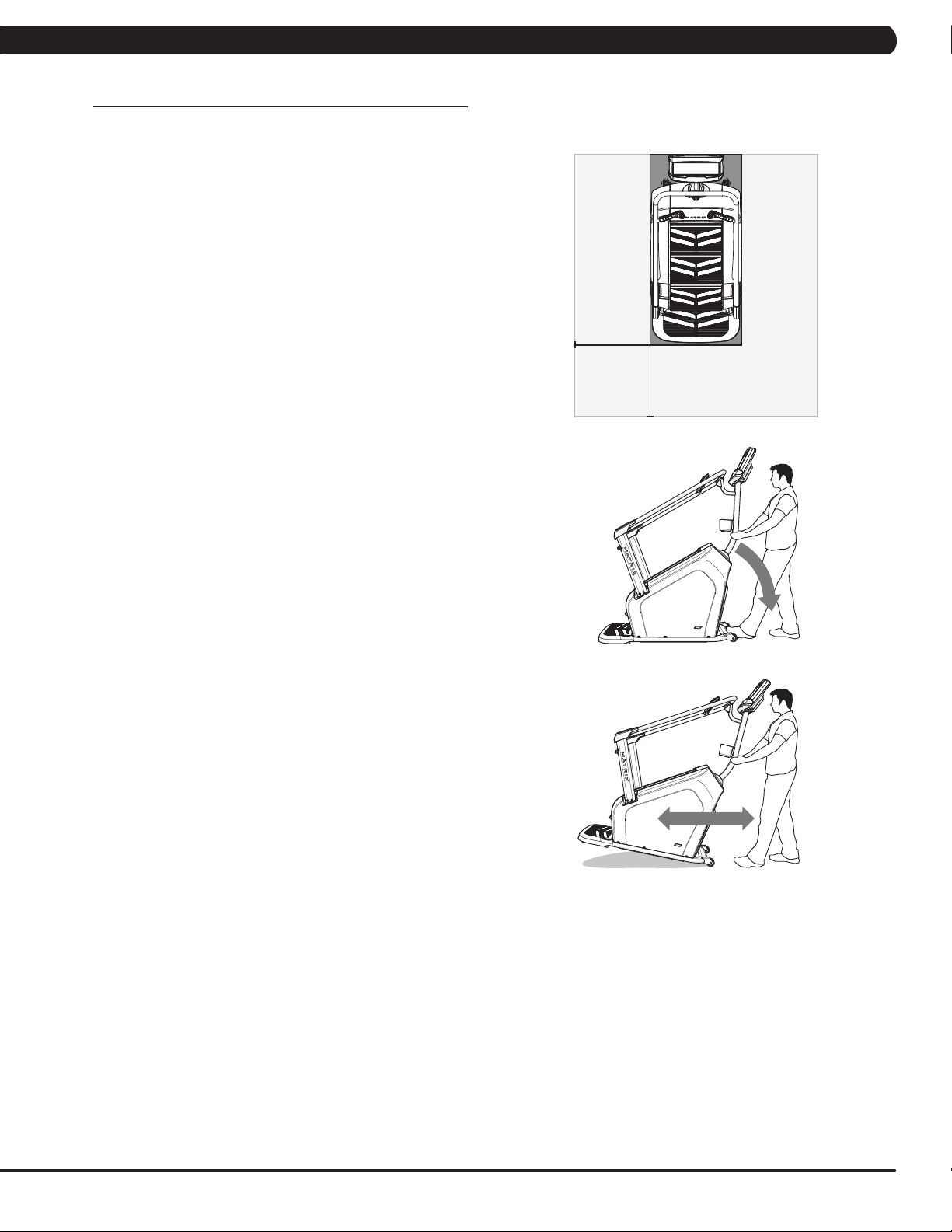

•Disconnect all power before servicing or moving the equipment. To

clean, wipe surfaces down with soap and slightly damp cloth only;

never use solvents. (See MAINTENANCE in OWNER’S MANUAL)

•The equipment should never be left unattended

when plugged in. Unplug from outlet when not in

use, and before putting on or taking off parts.

•Do not operate under blanket or pillow. Excessive heating can

occur and cause fire, electric shock, or injury to persons.

•Connect this exercise product to a properly grounded outlet only.

•At NO time should children under the age of 14

or pets be within 10 feet of the machine.

•Keep children under the age of 14 away from this

exercise equipment. Teenagers must be supervised

at all times while using this equipment.

•This equipment is not intended for use by persons with

reduced physical, sensory or mental capabilities, or lack

of experience and knowledge, unless they have been

given supervision or instruction concerning use of the

equipment by a person responsible for their safety.

•Use the equipment only for its intended use

as described in the owner’s manual.

•Do not use other attachments that are not recommended

by the manufacturer. Attachments may cause injury.

•Never operate the equipment if it has a damaged cord or

plug, if it is not working properly, if it has been dropped or

damaged, or immersed in water. Contact Customer Tech

Support at the number on the back cover to schedule service.

•Keep power cord away from heated surfaces. Do not carry

this unit by its supply cord or use the cord as a handle.

•Never operate the equipment with the air opening blocked.

Keep the air opening clean, free of lint, hair, and the like.

•To prevent electrical shock, never drop or

insert any object into any opening.

•Do not operate where aerosol (spray) products are

being used or when oxygen is being administered.

•To disconnect, turn all controls to the off

position, then remove plug from outlet.

•Do not use equipment in any location that is not

temperature controlled, such as but not limited to

garages, porches, pool rooms, bathrooms, car ports or

outdoors. Failure to comply may void the warranty.

•This equipment is intended for in-home use only. Do not

use this equipment in any commercial, rental, school or

institutional setting. Failure to comply will void the warranty.

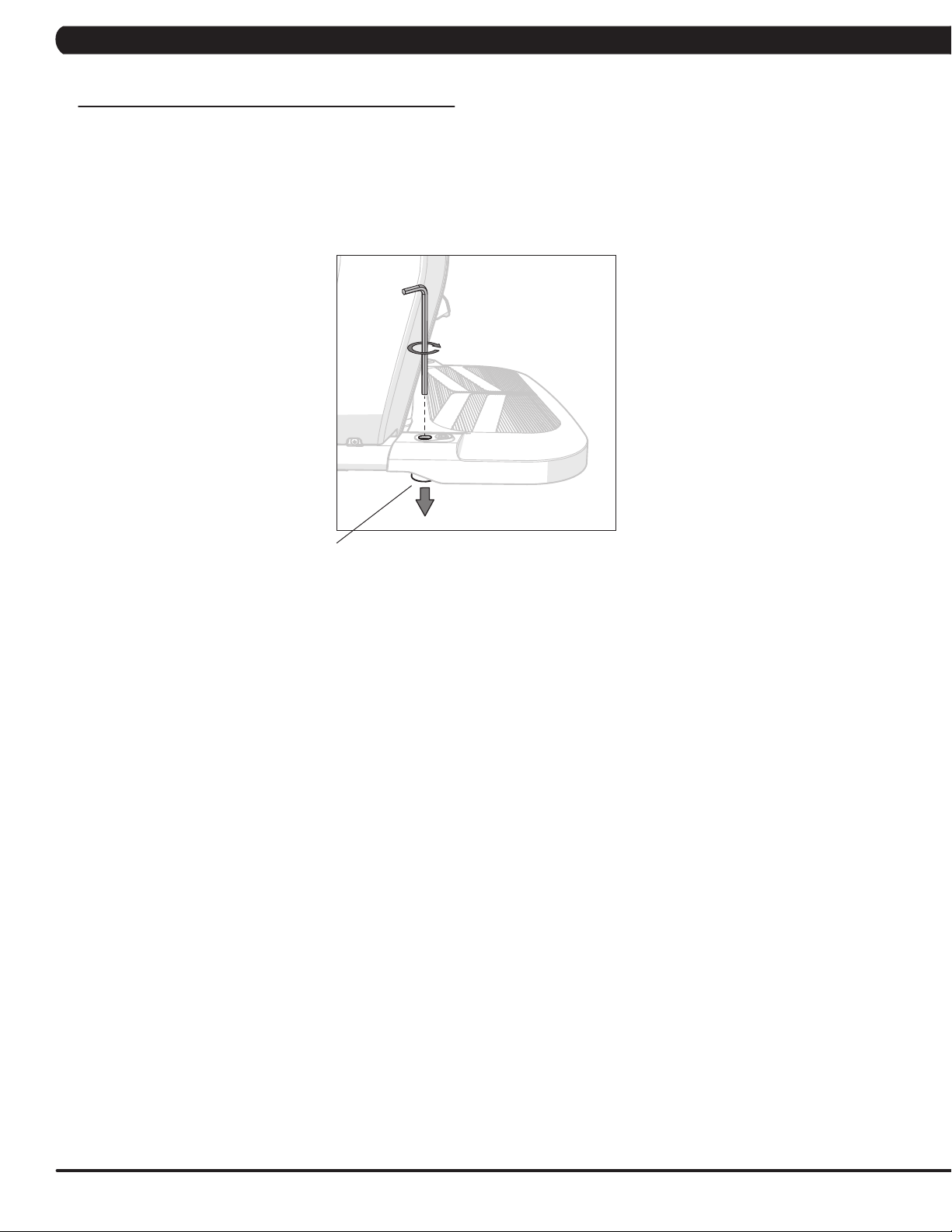

•Do not remove the console covers unless instructed

by Customer Tech Support. Service should only be

done by an authorized service technician.