9

8

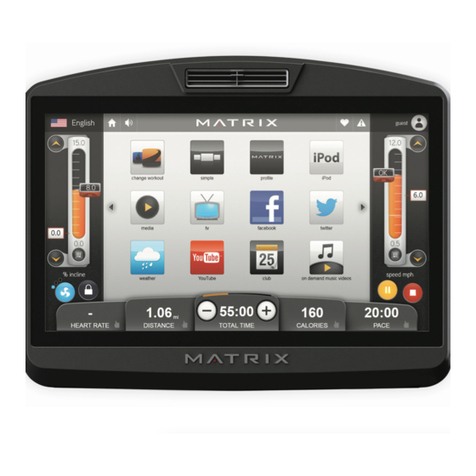

C5X CONSOLE DESCRIPTION

WORKOUTKEYS: Simple program view and selection buttons.

GO: One touch start.

ENTER: To confirm each program setting.

uP / DoWn leVel: Easy information and level selection.

UP/DOWNTIME: Easy information and time adjustment.

stoP: Ends workout and shows workout summary data.

NUMBERKEYPAD: Workout data input for workout setup. Level adjustment during workout.

COOLDOWN: Puts the Climb Mill into Cool Down Mode.

FAN: Allows for fan speed selection (fan has 3 operating speeds).

TOGGLEDISPLAY: Changes information displayed from top row to bottom one.

LANGUAGE: Select language.

4.1 CONSOLE DESCRIPTION

CHAPTER 4: CONSOLE OVERLAY AND WORKOUT DESCRIPTION

To set up a workout, choose the program wanted, then press ENTER.

Follow the prompts to begin your workout.

Go - Press to immediately begin a workout. Workout, resistance level,

and time will automatically go to default settings. All energy expenditure

values will be calculated using the default weight measurement.

manual - Manual allows the user to input more information while

defining their own workout. Calorie expenditure will be more accurate

when inputting information in Manual than by pressing GO.

rollinG Hills - The Rolling Hills program is a level based

program that automatically adjusts the resistance level to simulate real

terrain.

interVals - The Intervals program is a level based program that

automatically adjusts the resistance of the machine from low to high

intensity settings at regular intervals to burn calories.

Goal traininG - The Goal Training program is designed to help

users burn a target number of calories.

Calorie traininG - The Calorie Training program is designed

to help users burn a target number of calories.

Constant Watts - The Constant Watts program allows

you to vary your cadence or SPM and the machine's resistance will

adjust according to your selected goal. The quicker you step, the less

resistance for the goal selected.

Fat burn - The Fat Burn program is a level based workout that is

designed to help users burn fat through various resistance changes.

tarGet Heart rate - The Matrix Climb Mill comes with

standard digital contact heart rate sensors and are POLAR telemetry

compatible. The heart rate control workout mode allows the user

to program their desired heart rate zone, and the Climb Mill will

automatically adjust the level based upon the user's heart rate. The

heart rate zone is calculated using the following equation: (220-Age)*% =

target heart rate zone. The user must wear a POLAR telemetric strap or

continually hold onto the contact heart rate grips for this workout.

Locate the metal sensors on the handlebars of the Climb Mill. Notice

that there are two separate pieces of metal on each grip. You must be

making contact with both pieces of each grip to get an accurate heart

rate reading. You can grab these sensors in any program to view your

current heart rate.

FITNESSTEST(WFI) - The WFI (Wellness Fitness Initiative)

protocol is a test used by firefighters in a series of intervals lasting a

maximum of 16 minutes, where the speed is increased every minute

until the Target Heart Rate is exceeded for 15 seconds. When the

test is complete, the display provides a summary of V)2max, Highest

SPM, Elapsed Time, and Target Heart Rate. The test requires constant

monitoring of the user's heart rate, so the use of a telemetric heart rate

strap is highly recommended.

CPAT

The Candidate Physical Ability Test (CPAT) is a new minimum requirement

for the position of Firefighter. The job of a Firefighter is one of the most

physically demanding jobs in North America. Participants wear a 50-pound

(22.68-kg) vest to simulate the weight of self-contained breathing

apparatus (SCBA) and firefighter protective clothing. An additional 25

pounds (11.34 kg), using two 12.5-pound (5.67-kg) weights that simulate

a high-rise pack (hose bundle), is added to your shoulders for the stair

climb event. The candidate must maintain 60 SPM (steps per minute) for

3 minutes.

FITNESSTEST(SUBMAXIMAL)- The Submaximal test

measures cardiovascular fitness and provides an estimated Sub-maximal

VO2 max result. This assessment is a 4 stage test lasting 3-5 minutes

where the speed is increased until your Heart Rate is between 115 - 150

bpm for 2 of the stages. When the test is complete, a Fitness Rating is

displayed as High, Good, Average, Fair, or Low along with your age and

VO2 max. The test requires constant monitoring of the user's heart rate,

so the use of a telemetric heart rate strap is highly recommended.

FITNESS RATING NORMS (V02 MAX)

AGE 20-29 30-39 40-49 50-59 60+

MEN

HIGH 51.4+ 50.4+ 48.2+ 45.3 42.5+

GOOD 51.3-46.8 50.3-44.6 48.1-41.8 45.2-38.5 42.4-35.3

AVERAGE 46.7-42.5 44.5-41.0 41.7-38.1 38.4-35.2 35.2-31.8

FAIR 42.4-39.5 40.9-37.4 38.0-35.1 35.1-32.3 31.7-28.7

LOW 39.4 OR

LESS

37.3 OR

LESS

35.0 OR

LESS

32.2 OR

LESS

28.6 OR

LESS

WOMEN

HIGH 44.2+ 41.0+ 39.5+ 35.2+ 35.2

GOOD 44.1-38.1 40.9-36.7 39.4-33.8 35.1-30.9 35.1-29.4

AVERAGE 38.0-35.2 36.6-33.8 33.7-30.9 30.8-28.2 29.3-25.8

FAIR 35.1-32.3 33.7-30.5 30.8-28.3 28.1-25.5 25.7-23.8

LOW 32.2 OR

LESS

30.4 OR

LESS

28.2 OR

LESS

25.4 OR

LESS

23.7 OR

LESS

4.2 WORKOUT SETUP STEPS

CHAPTER 4: CONSOLE OVERLAY AND WORKOUT DESCRIPTION