Installation and Operational Instructions for

EAS®-element clutch

Sizes 6 –14 (B.4.3.EN)

11/02/2013 TK/GH/SU Chr. Mayr GmbH + Co. KG

Eichenstraße 1, D-87665 Mauerstetten, Germany

Tel.: +49 8341 804-0, Fax: +49 8341 804-421

Page 4 of 11 www.mayr.com, E-Mail: info@mayr.com

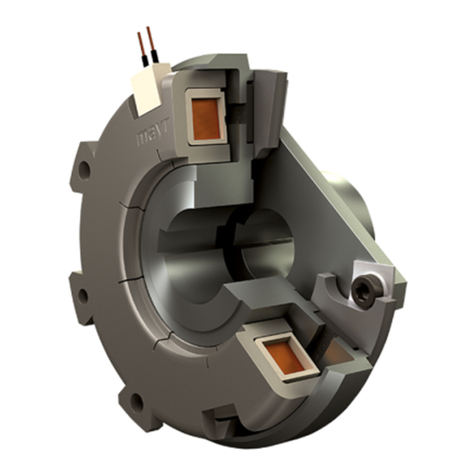

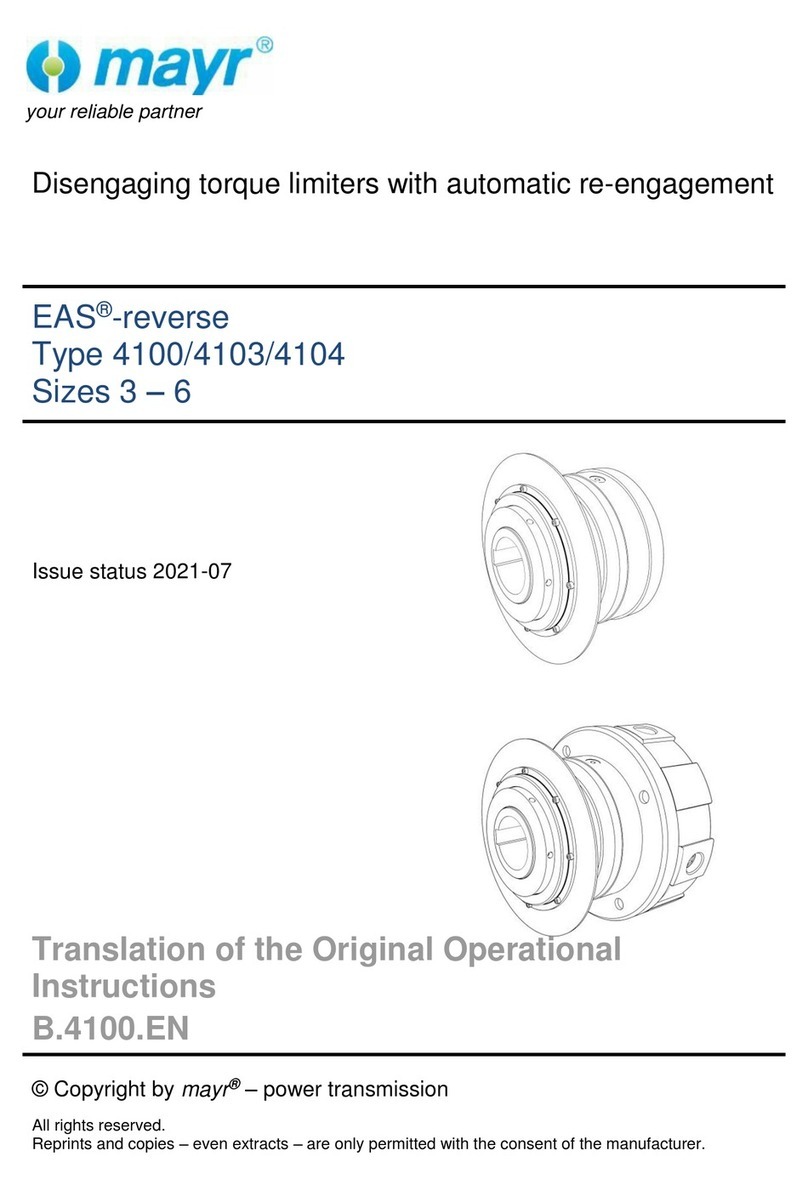

Design

The EAS®-element clutches are designed as mechanically

disengaging overload clutches with overload elements (2)

according to the ball-detent principle.

Function

The EAS®-clutch protects the drive line from excessively high,

unpermitted torque impacts which can occur due to unintentional

blockages.

After overload has taken place, the transmitting mechanism is

completely disconnected. Only the bearing friction continues to

have an effect.

This means that no re-engagement impacts or metallic sliding

movements occur on the clutch torque transmission geometries

when using this clutch variant.

When in operation, the set torque is transmitted from the hub (1)

(input) via the pressure flange (11) or the flange hub (24)

(flexible coupling) onto the output.

If the set limit torque is exceeded (overload), the clutch

disengages.

On disengagement, the bolts (2.2.1) in the overload elements (2)

perform an axial movement (stroke);

a contactless limit switch provided customer-side can be used

here for recognition of overload.

The bolts (2.2.1) remain disengaged. Input and output are

separated residual torque-free.

After-acting masses can run free.

After overload occurrence, the clutch has no

load-holding function.

The run-out time after disengagement must be

max. 10 minutes.

In order to prepare the clutch for renewed operation, the

bolts (2.2.1) must be re-engaged manually (see section Re-

engagement).

Scope of Delivery / State of Delivery

The EAS®-clutch is manufacturer-assembled ready for

installation.

The torque is set manufacturer-side according to the

customer's request (please compare the torque stipulated in

the order with the torque imprinted/engraved in the

identification).

Otherwise, the clutch must be adjusted to the required

torque by using the Adjustment Diagram (attachment) (see

section Torque Adjustment).

Please check the scope of delivery according to the Parts List as

well as the state of delivery immediately after receiving the

goods.

mayr®will take no responsibility for belated complaints.

Please report transport damage immediately to the deliverer.

Please report incomplete delivery and obvious defects

immediately to the manufacturer.

General Installation Guidelines

The bore tolerances in the hub (1) and in the flange hub (24) are

produced to tolerance quality H7. The surface roughness depth

in the bores is produced to Ra 1,6 µm.

Please secure screws with Loctite 243 (medium hard).

Please observe the screw tightening torques

acc. Table 1!

Before initial operation of the clutch, please

remove the eyebolt (28) (installation aid).

Mounting onto the Shaft

Mount the EAS®-element clutch using a suitable mounting device

onto the drive shaft and secure it axially (e.g. using a washer

and a screw, screwed into the shaft threaded centre hole).