Installation and Operating Instructions

for ROBA-stop®-S Size11 (B.8.3.1.GB)

25/10/2005 K/TK/BG/KR Chr. Mayr GmbH + Co. KG Tel.: 08341 / 804-241

Eichenstraße 1 Fax: 08341 / 804-422

87665 Mauerstetten http://www.mayr.de

Safety Regulations

With this safety regulations no claim on completeness is raised!

Attention!

Hazardous conditions when contacting hot

connections and components.

Only qualified and well-trained specialists should work on

the units to avoid any personal injury or damage to

machinery.

Danger!

If the electromagnetic brake is used in an improper way.

If the electromagnetic brake has been modified or

reconverted.

If the relevant standards of the safety or installation

conditions are not observed.

Attention!

The installation and operating instructions must be

read carefully and all safety regulations observed

before installation and initial operation as danger to

personnel and damage to machinery may be

caused.

The electromagnetic brakes are developed and

manufactured in conformance with the temporally

known rules of the technology and they are basically

considered as fail-safe at the time of the delivery.

Attention:

Based on the guideline 94/9/EC (ATEX-guideline) this product is

not suitable for the application in potential explosive areas

without evaluation of the conformity.

Observe!

Only qualified and well trained specialists who are familiar

with the transport, installation, initial start-up, maintenance

and operation of the units as well as with the relevant

standards may carry out the corresponding works.

Technical data and indications (Type tag and

documentation) are to be kept absolutely.

Correct supply connection according to Type tag.

Supply connections must not be released and assembly,

maintenance or repair must not be made when the unit is

energized.

Electrical leads must not be under tension when

connected.

Check current carrying components regarding damage

before installation. Current carrying components must not

be in contact with water or other liquids.

The braking torque does not exist any more, if the friction

lining and/or friction surface come into contact with oil or

grease.

Intended use

mayr®-brakes are determined for the use in machines and

equipment and may only be used for the ordered and confirmed

purpose.

The use beyond of the corresponding technical indications is

considered as incorrect.

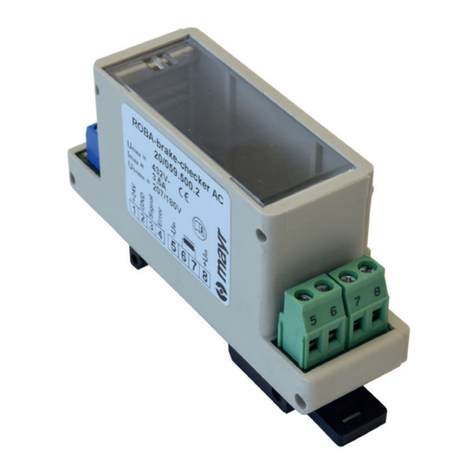

Notes to the electromagnetic compatibility

(EMC) There are no emissions from the listed single

components within the meaning of the EMC-

directive 89/336/EEC, however, increased

interference levels can occur when working

components are operated outside their specification

limits as for example, energising the brake with

rectifiers, phase demodulators or ROBA®-switch in

the line side.

Therefore, the installation and operating instructions

must be read carefully the EMC-directives are to be

observed.

Conditions of the unit

The catalogue values are reference values, which

can deviate in some cases. When selecting the

brake, site of installation, braking fluctuations,

permissible friction work, behaviour during run-in,

wear and ambient conditions are to be carefully

checked and agreed with the unit manufacturer.

Observe!

The mounting and connecting dimensions at the site of

installation must match to the size of the brake.

The brakes are designed for a relative switch on period

of 100 %.

The brakes are designed for a dry running only.

Should oil, grease, water or similar materials come in

contact with the friction surfaces the braking torque could

be reduced.

The braking torque depends on the corresponding running-

in condition of the brake.

The metallic surface of the brake is protected against

corrosion arranged by the factory.

Protection class I

The protection is not only based on the basis isolation, but that

all conductive components must be connected with the

protective conductor (PE) of the fixed installation. In case the

basis isolation fails, no contact voltage can remain existing.

(VDE 0580).

Protection IP 67:

Dust-tight and protection against contact as well as protection

against temporary submerging into water.

Ambient temperature –20°up to +40 °C

Attention!

The torque could be severely reduced in case of temperatures

over or under the freezing point due to dewing or the rotors can

freeze respectively. The user must provide corresponding

counter measures.

Thermal class F (+155 °C)

The magnetic coil as well as the casting compound is designed

for a max. operating temperature of +155 °C.