Operational Instructions for

EAS®-reverse Type 4100/4103/4104

Sizes 3 –6 (B.4100.EN)

14/07/2021 VN/GF/GC/SU Chr. Mayr GmbH + Co. KG

Eichenstraße 1, D-87665 Mauerstetten

Phone: +49 8341 804-0, Fax: +49 8341 804-421

Page 8 of 16 www.mayr.com, E-Mail: public.mayr@mayr.de

4 Installation

4.1 Installation preparations (customer-side)

Bore or shaft surface quality:

Ra = 0.8 µm acc. ISO 4762.

Standard bore or shaft tolerances: h6.

Standard tolerance of the keyway: JS9.

4.2 Important Installation Guidelines for

Types 4103/4104

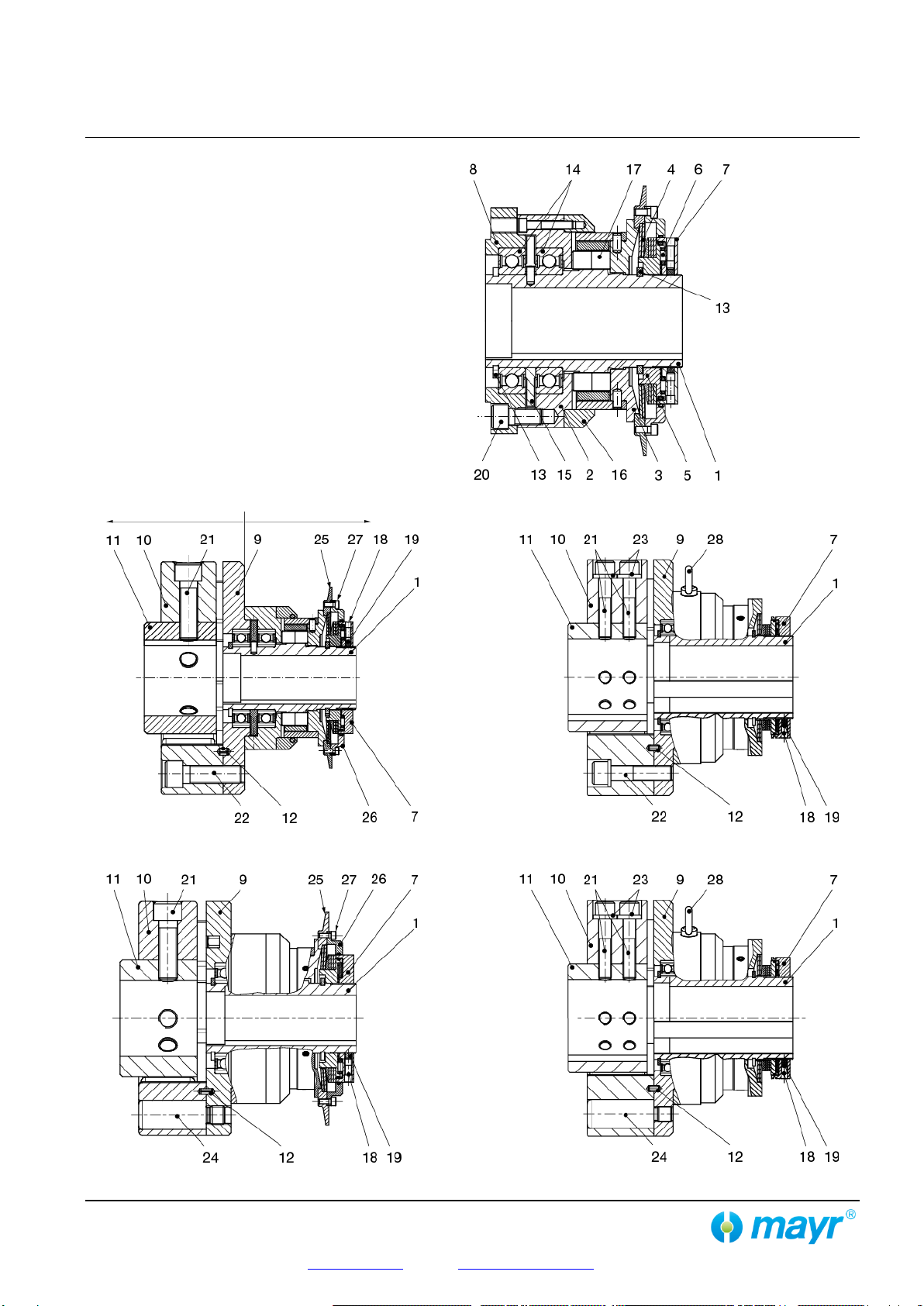

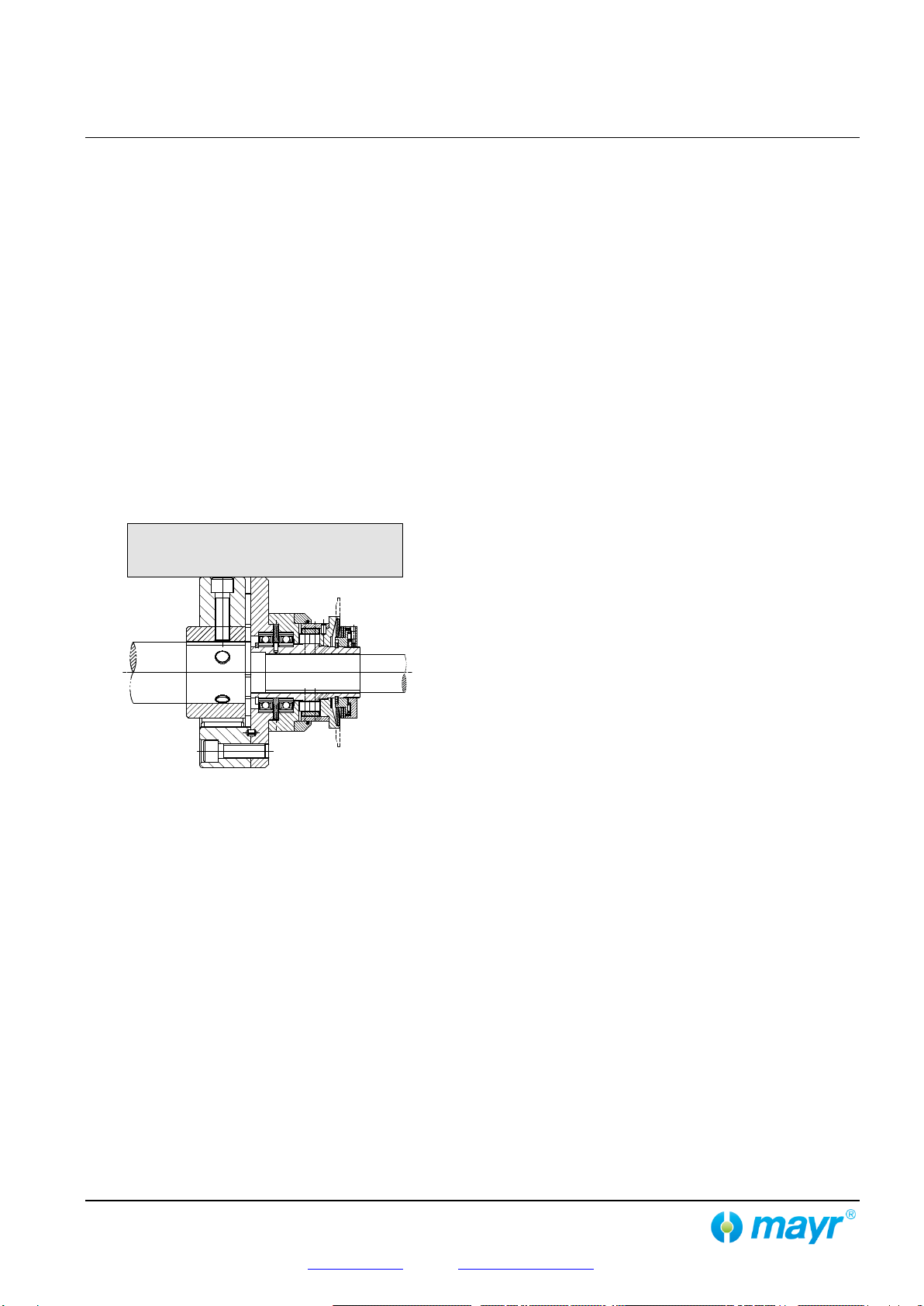

Tighten all cap screws (21) which connect the

elastomer ring (10) with the hub (11) to the

tightening torque according to the table (section

3.4) using the torque wrench.

When tightening the screw, ensure that the

aluminium bushing in the elastomer ring (10) is not

turned as well; instead it should sit straight (Fig.

6). In order to reduce the friction between the

screw head and the alumnum part, you must apply

a small amount of grease under the screw head

before starting the installation. If necessary,

prevent a rotation (tilt) of the elastomer ring (10)

when tightening the screws through the

application of counter-pressure using a suitable

tool.

If the clutch is pre-assembled on delivery, it should

not be dismantled again, but rather installed in its

pre-assembled state.

Checking the tightening torques.

4.3 Guidelines for elastomer ring

Please only use the screws included in

delivery - they are marked by a colored

mass (blue) on the threads. This mass

contains micro-capsulated adhesive, which

glues the screws in the thread and

therefore reliably protects against

loosening. After screwing in, the hardening

time of this adhesive at room temperature

(20 °C) is approximately 4 - 5 hours to take

adequate effect. The clutch should not be

operated beforehand.

The hardening is fully completed after 24

hours. Higher temperatures accelerate the

hardening, e.g. the hardening time is only

15 minutes at +70 °C (heated via a warm

air blower). The micro-capsulated adhesive

is temperature-resistant from -80 °C to

+90 °C, and the screws can be re-used a

maximum of 3 times.

Any adhesive which may have been

removed during screwing in, will get caught

between the hub (11) and the aluminium

part. This is not a disadvantage; on the

contrary, it is an advantage as this

increases the frictional locking between

these parts. Attention: Anaerobic adhesives

(such as Loctite, Omnifit etc.) loosen the

rubber adhesion on the metal and therefore

lead to destruction of the clutch. If possible,

do not use these adhesives. If using these

adhesives cannot be avoided (e.g. for

securing screws), then apply economically,

so that no excess adhesive wets the

rubber. We cannot be held reliable for

rubber parts that have become defective

due to adhesives.