Installation and Operational Instructions for EAS®-compact®

Ratchetting clutch, Type 49_._ _0._ Size 4

Synchronous clutch, Type 49_._ _5._ Size 4 (B.4.14.4.EN)

17/03/2021 TK/GC/NU Chr. Mayr GmbH + Co. KG

Eichenstraße 1, D-87665 Mauerstetten, Germany

Phone: +49 8341 804-0, Fax: +49 8341 804-421

Page 10 of 22 www.mayr.com, E-Mail: public.mayr@mayr.com

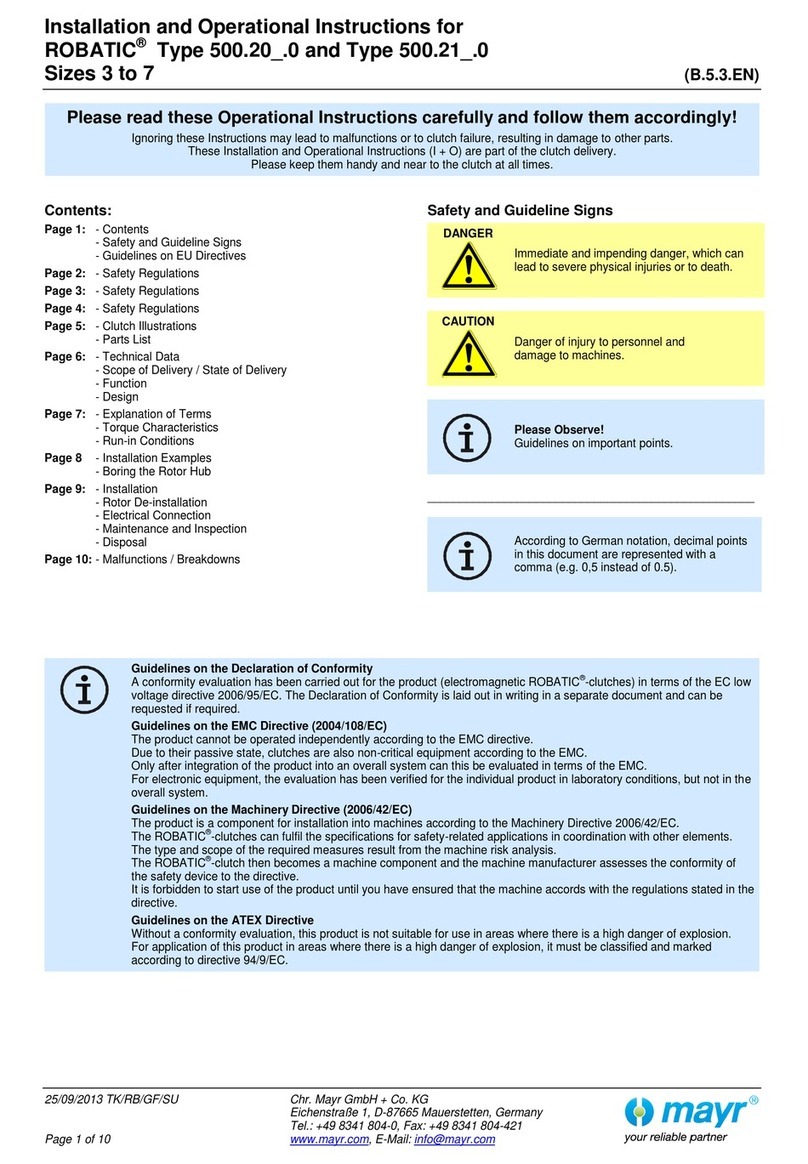

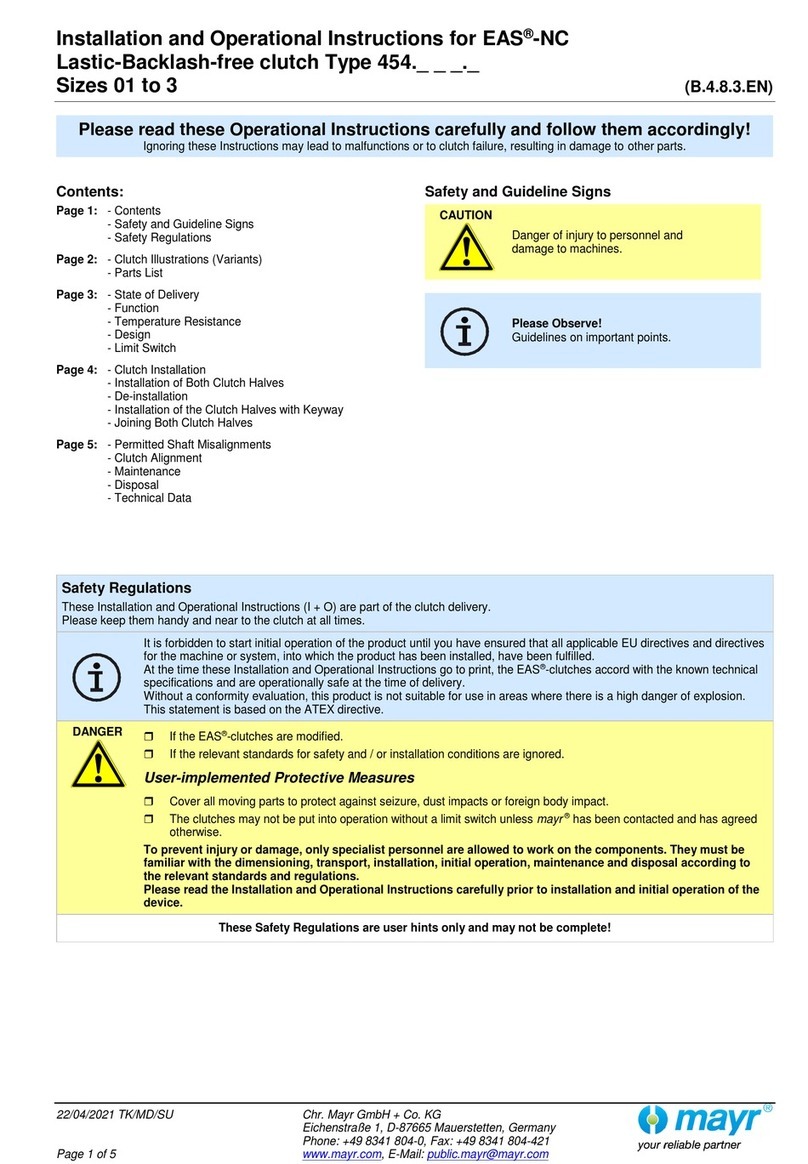

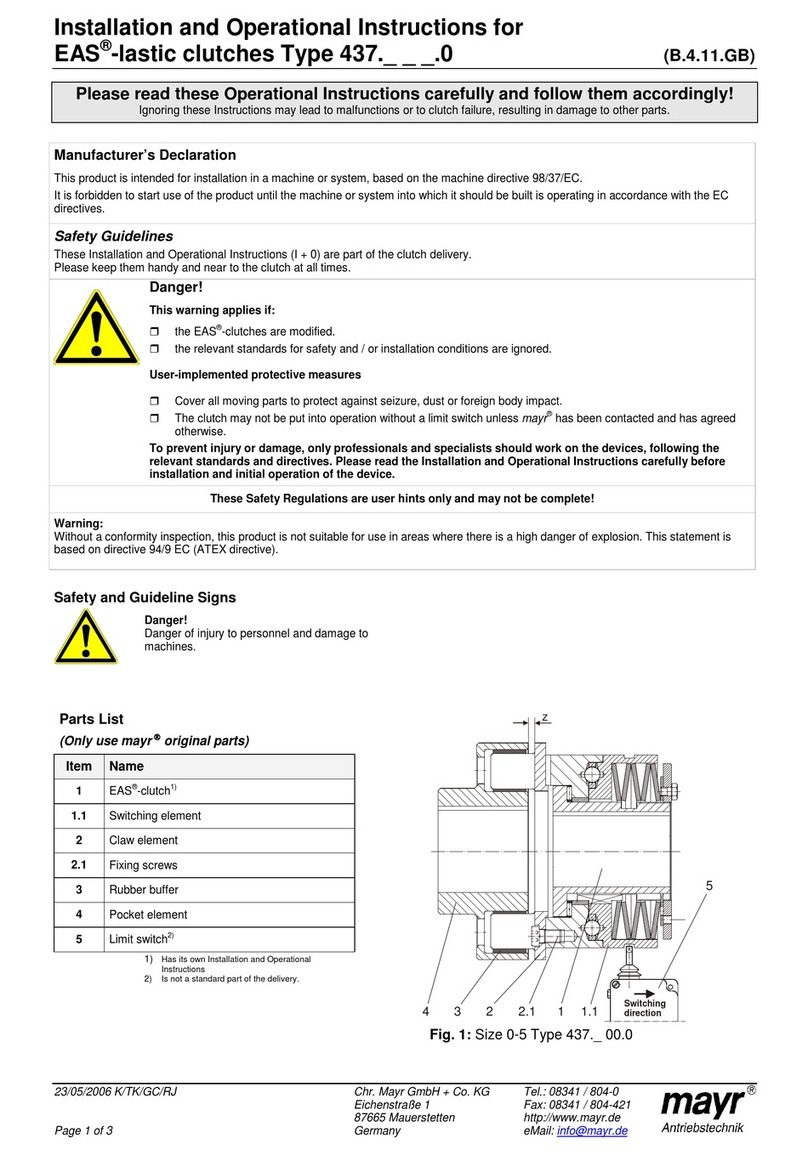

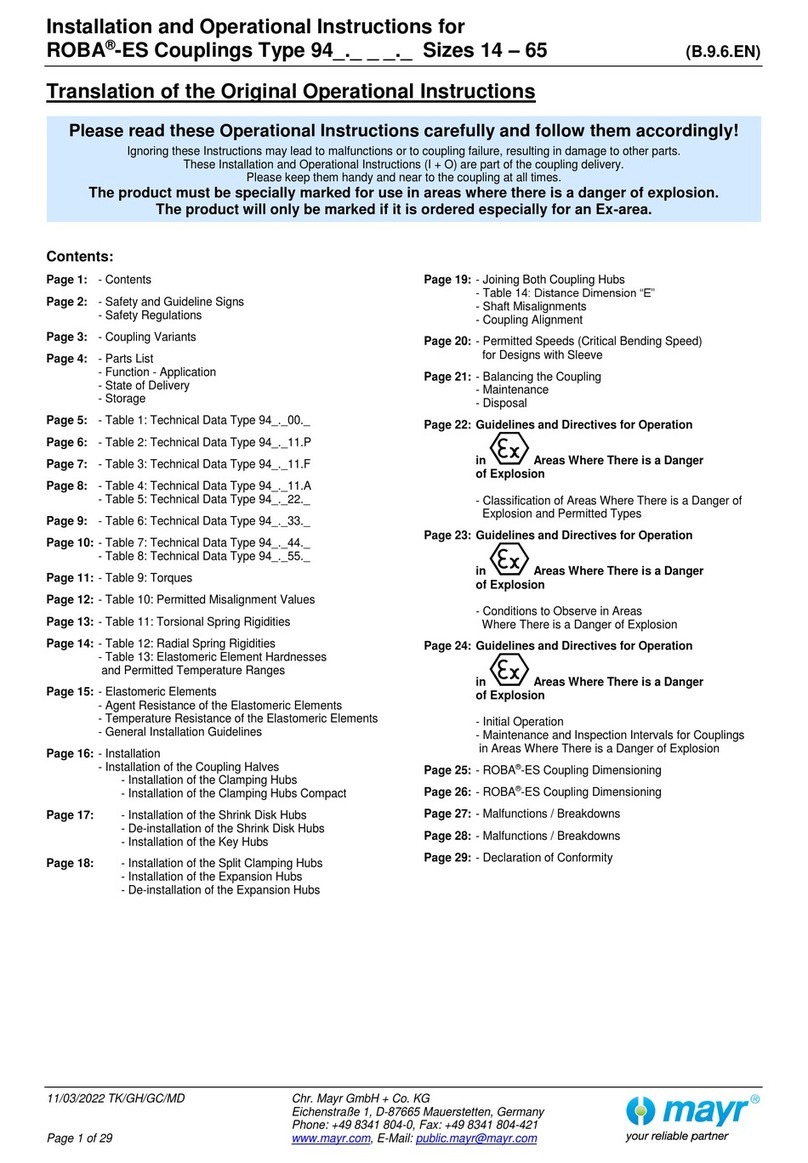

Cup Spring Layering (Fig. 5)

Correct cup spring layering is a prerequisite for problem-free

clutch function and torque adjustment.

Torque range “medium”:

one cup spring (Type 49_.5_ _._)

Torque range “high”:

two cup springs (Type 49_.6_ _._)

Torque range “very high”:

four cup springs (Type 49_.7_ _._)

Torque range “maximum”:

five cup springs (Type 49_.8_ _._)

1x layered 2x layered

Type 49_.5_ _._ Type 49_.6_ _._

4x layered 5x layered

Type 49_.7_ _._ Type 49_.8_5._

Fig. 5

Mounting onto the Shaft

EAS®-compact®clutches Size 4 include

cone bushings, shrink disks, clamping hubs or keyways as part of

the standard delivery.

During installation of cone bushings or shrink disks, please

observe the following:

Recommended shaft tolerance

for cone bushings: h6

for clamping hubs: see Table 8

for shrink disk hubs: see Tables 9 and 12

Shaft surface: finely turned or ground

(Ra = 0.8 µm).

Shaft material: yield point at least 400 N/mm2,

e.g. C45 +QT, 42CrMoS4 +QT.

Degrease or remove conserving layers on the shafts and

bores before installing the clutch.

Greasy or oily bores or shafts do not transmit the torques

defined in the catalogue.

Mount the clutch or clutch hubs onto both shaft ends using a

suitable device and bring it / them into the correct position.

Tighten the tensioning screws (12) of the cone bushing (11) in

2 steps cross-wise and then in 3 to max. 6 tightening

sequences evenly using a torque wrench to the torque stated

in Table 5.

Type 494.-:

Tighten the tensioning screws (34) in the shrink disks (38)

stepwise (in 3 to max. 6 tightening sequences) and cross-

wise evenly using a torque wrench to the torque stated in

Table 5.

Type 496.-:

Tighten the tensioning screws (21) in the shrink disks (20)

using a torque wrench evenly and one after the other in max.

6 sequences to the torque stated in Table 5.

The transmittable torques of the shaft-hub connection are

dependent on the bore diameter and the quality of the drive

shafts used. Please observe the respective transmission

Tables 8, 9 and 12.

The clutch or clutch hub carries out an axial

movement in the direction of the cone bushing

(11) when tightening the cone bushing (11).

Because of this effect, please ensure that on

the EAS®-compact®clutch with disk pack (Type

496._ _ _._), first the cone bushing (11) is

completely tightened, then the other (disk pack)

side.

De-installation

of the Cone Bushings and Shrink Disks

In the cone bushings and the shrink disks, there are tapped

extracting holes next to the tensioning screws.

1) Loosen all tensioning screws by several thread turns.

2) Screw out the tensioning screws located next to the tapped

extracting holes and screw them into the tapped extracting

holes up to their limits.

Then tighten these screws until the tensioning connection

loosens.