Installation and Operational Instructions for

smartflex®-couplings Types 932.3_3 and 932.433 (B.9.8.GB)

20/08/2008 TK/NV/SU/GC Chr. Mayr GmbH + Co. KG Tel.: 08341 / 804-241

Eichenstraße 1 Fax: 08341 / 804-422

87665 Mauerstetten http://www.mayr.de

Page 2 of 6 Germany eMail: info@mayr.de

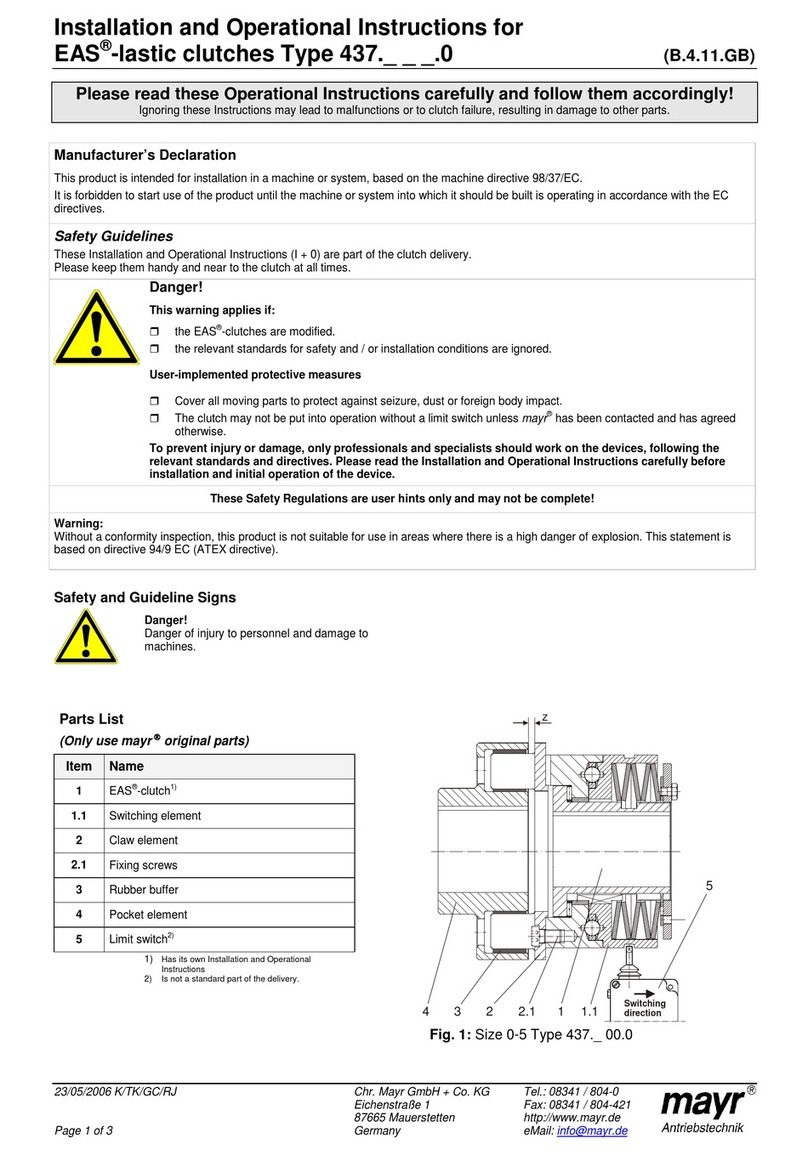

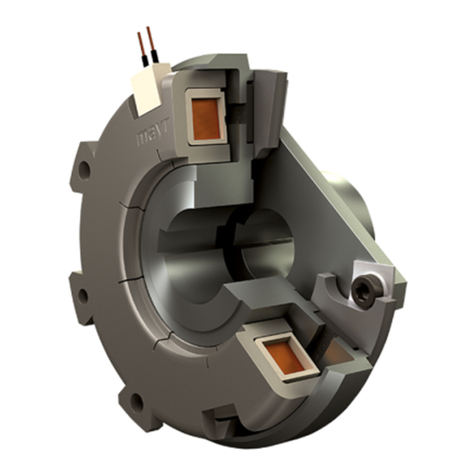

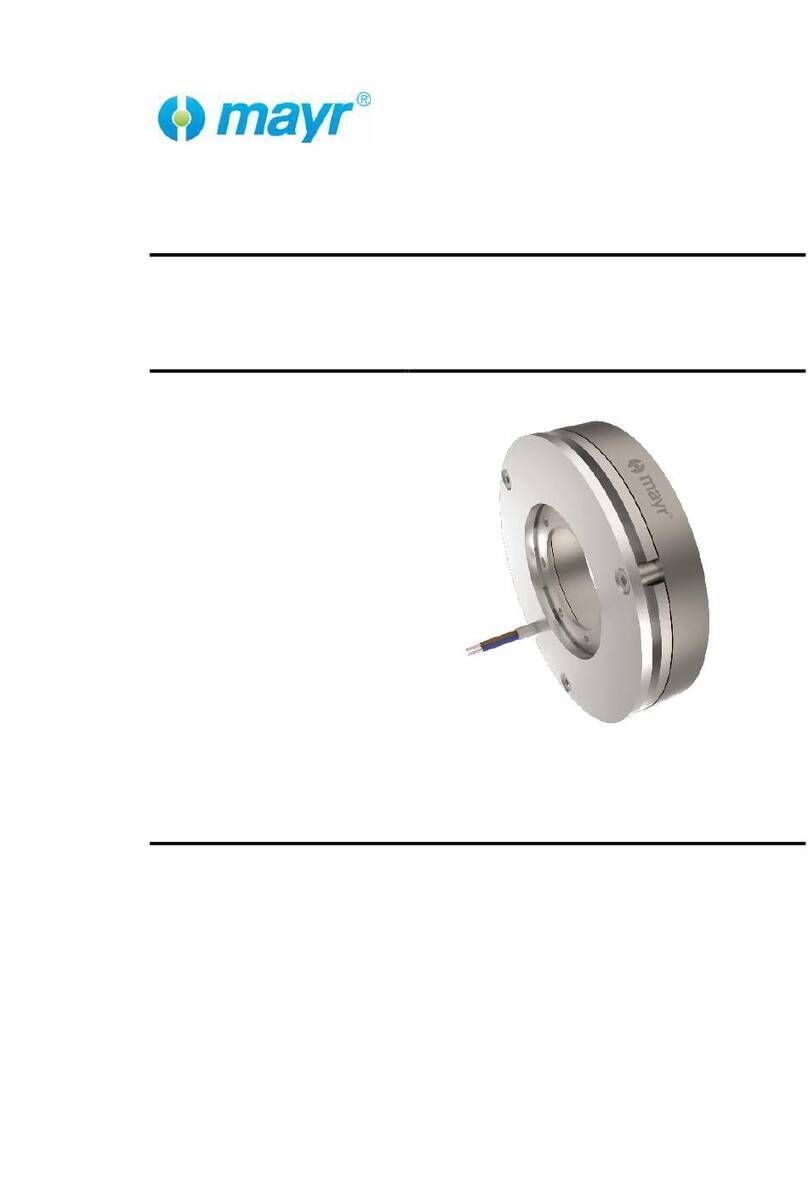

Parts List

Only use mayr®original parts

1 Steel bellows

2 Clamping ring

3 Holding spring

4 Cap screw

5 Reducing bushing

6 Reducing bushing with tapered bore

7 Washer

Fig. 1

Table 1: Technical Data

smartflex®Size 0 1 2 3 4 5

Bore reducing bushing (Item 5) from – to [mm]

8 – 19 11 – 25

16 – 36

18 – 50

30 – 62

40 – 85

Tapered bore (Item 6) [mm]

- - - 16 16 - - - - - - - - -

Coupling nominal torque TKN [Nm]

16 40 100 200 400 700

Max. speed nmax. [rpm]

10000 8000 6000 4000 3000 2500

Tightening torque clamping screw (Item 4) [Nm]

10±5% 14±5% 17±5% 41±5% 77±5% 133±5%

Axial displacement ∆Kaon Type 932.3_3 [mm]

±0,4 ±0,6 ±0,8 ±0,8 ±0,8 ±0,6

Axial displacement ∆Kaon Type 932.433 [mm]

- - - ±0,3 ±0,4 ±0,4 ±0,6 ±0,6

Radial misalignment ∆Kron Type 932.3_3 [mm]

0,3 0,4 0,5 0,5 0,5 0,5

Radial misalignment ∆Kron Type 932.433 [mm]

- - - 0,1 0,1 0,1 0,1 0,1

Angular misalignment ∆Kwon Type 932.3_3 [°]

3 3 3 3 1,5 1,0

Angular misalignment ∆Kwon Type 932.433 [°]

- - - 1,5 1,5 1,5 1,2 1,0

Table 2: Clamping Connection Bores and Corresponding Transmittable Torques TR [Nm]

Size Ø

8 Ø

9 Ø

11

Ø

12

Ø

14

Ø

16

Ø

18

Ø

19

Ø

20

Ø

22

Ø

25

Ø

28

Ø

30

Ø

32

Ø

35

Ø

36

Ø

38

Ø

40

Ø

42

Ø

45

Ø

48

Ø

50

Ø

55

Ø

60

Ø

62

Ø

65

Ø

70

Ø

75

Ø

80

Ø

85

0 9,6

11

14

16

16

16

16

16

1 24

26

31

35

39

40

40

40

40

2 60

68

72

75

84

100

100

100

100

100

100

3 120

127

133

147

167

187

200

200

200

200

200

200

200

200

200

200

4 240

256

280

290

305

320

340

360

390

400

400

400

400

5 420

440

475

510

530

580

640

660

690

700

700

700

700

Table 3: Preferred Bores

Size Preferred bores Ø dH7

0 8, 9, 10, 11, 12, 14, 15, 16, 18, 19

1 11, 12, 13, 14, 15, 16, 18, 19, 20, 22, 24, 25

2 16, 17, 18, 19, 20, 22, 24, 25, 26, 28, 30, 32, 35, 36

3 19, 20, 22, 24, 25, 28, 30, 32, 35, 36, 38, 40, 42, 45, 48, 50

4 30, 32, 35, 36, 38, 40, 42, 45, 48, 50, 55, 60, 62

5 40, 42, 45, 48, 50, 55, 60, 62, 65, 70, 75, 80, 85