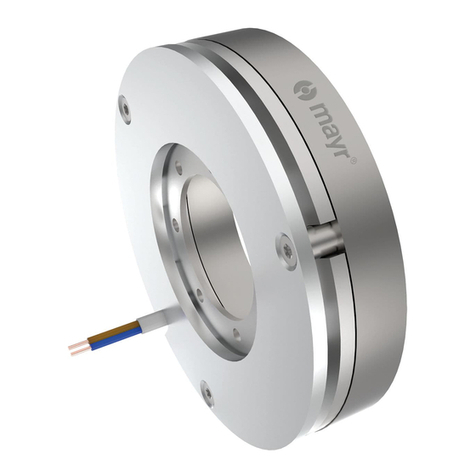

Installation and Operational Instructions for

ROBA-stop®Holding Brake Type 820.61_._ (B.1110.6.GB)

08/02/2010 K/GC/RJ/GF Chr. Mayr GmbH + Co. KG Tel.: 08341 / 804-0

Eichenstraße 1 Fax: 08341 / 804-421

D-87665 Mauerstetten http://www.mayr.de

Installation Conditions

Before mounting the brake, please observe the following

points:

The eccentricity of the shaft end against the mounting pitch

circle may not exceed 0,2 mm (on sizes 3 – 6),

or 0,4 mm on larger brakes.

The positioning tolerance of the thread for the

cap screws (13) may not exceed 0,2 mm.

The axial eccentricity deviation of the screw-on surface to

the shaft may not exceed the permitted axial eccentricity

tolerance according to DIN 42955 R.

The related diameter is the pitch circle diameter of the

brake attachment.

Larger deviations can lead to a drop in torque, to permanent

slipping on the rotor and to overheating.

The tolerances of the hub and the shaft must be selected

so that the hub toothing is not widened (please observe the

maximum join temperature of 200 °C). Widening the

toothing leads to the rotor clamping on the hub and

therefore to brake malfunctions.

(Recommended hub - shaft tolerance H7/k6).

The hub (1) must be positioned so that the

rotor toothing (35) carries holohedrally.

The rotor and the brake surfaces must be free of oil and

grease.

A suitable counter friction surface (steel or cast iron) must

be used. Sharp-edged interruptions on the friction surface

are to be avoided. Recommended surface quality in the

friction surface area: Ra = 1,6 µm.

Friction surfaces made of grey cast iron are to be

rubbed down with fine sandpaper (grain ≈400).

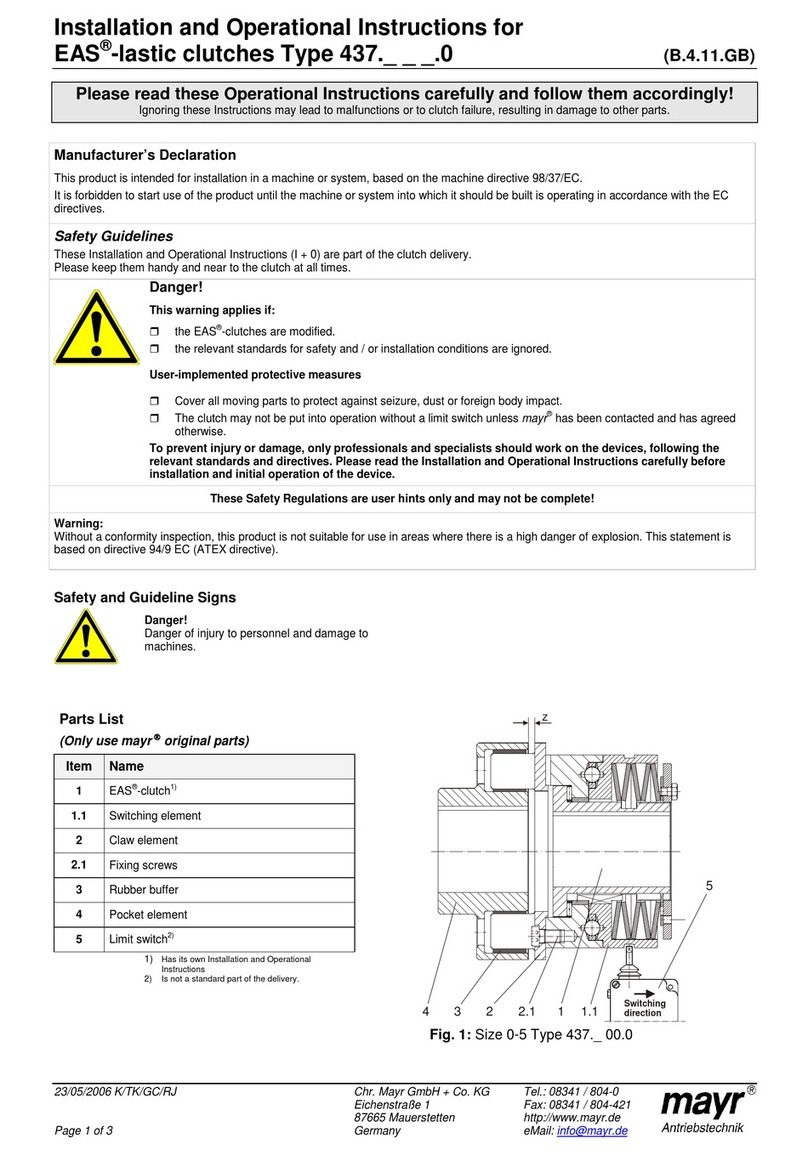

Installation

Mount the gear hub (1) onto the shaft and secure it axially.

Please avoid damage to the toothing.

Mount the gear hub (1) so that the rotor (35) toothing stays

in complete contact even after the friction linings (8) have

become worn.

Push the rotor (35) by hand onto the gear hub (1). The rotor

collar should be facing in the direction of the brake.

Make sure that the toothing moves easily.

Do not cause damage.

Screw on the brake using the fixing screws included in

delivery (13), and secure using spring rings (28).

Check the nominal air gap „a“ according to Table 1. The

nominal air gap must be present.

Observe the screw tightening torques according to Table 1.

The shoulder screws (10) prevent the individual parts from

falling apart. They do not affect the brake function and

should not be removed during installation.

Table 1

ROBA-stop®

size 3 4 5 6 7 8 9 10 11

torque (pos. 13)

[Nm]

3 3 6 8 8 10 10 10 40

Nominal air gap

“a” [mm]

0,20

0,20

0,25

0,25

0,35

0,35

0,40

0,40

0,50

Max. permitted

working air gap*

[mm]

0,30

0,30

0,40

0,45

0,50

0,50

0,50

0,50

0,70

* as the operating temperature increases, the max. air gap can decrease.

Air Gap Adjustment

The working air gap „a“ between the armature disk (5) and the

coil carrier (2) is set manufacturer-side to the nominal dimension,

see Fig. 2 and Table 1.

However, as the rotor (35) wears down, the air gap increases. By

turning the threaded distance ring, (31) it is possible to reset the

nominal air gap. Adjustment must take place at the latest when

the maximum permitted working air gap (acc. Table 1) has been

reached.

Adjustment

1. Take a screw plug out of the threaded distance ring (31).

Measure the air gap before adjustment in de-energised

conditions using a sensor gauge. The difference between

the measured air gap and the nominal air gap „a“ must be

readjusted according to Table 1.

2. Loosen the fixing screws (13).

3. Loosen the clamping bolt (59) and the lock washer (58).

4. Turn the threaded distance ring (31) anti-clockwise (facing

the rear side of the brakes). Turn the distance ring (31) one

graduation line on the imprinted scale. This equals an air

gap adjustment of 0,05 mm on sizes 3 to 6 and of 0,1 mm

on sizes 7 to 11.

5. Tighten the fixing screws (13) and observe the tightening

torques according to Table 1.

6. Tighten the clamping bolt (59).

7. Check the air gap. The nominal air gap „a“ according to

Table 1 must be present.

Re-adjustment can be repeated until the threaded distance ring

(31) lies against the coil carrier (2) collar, see Fig. 2. This contact

prevents unpermitted wear on the rotors (35). If no more re-

adjustment is possible, the rotor (35) must be replaced.

Fig. 2

Braking Torque Adjustment

ROBA-stop®brakes are set manufacturer-side to the braking

torque requested on order. By turning the set screws (14) to the

left, the braking torque is reduced. By turning them to the right,

the braking torque is increased.

During braking torque adjustment, all the set screws (14) must

be adjusted evenly.

Warning!

Do not confuse the set screws (14) with the fixing

screws (13)!