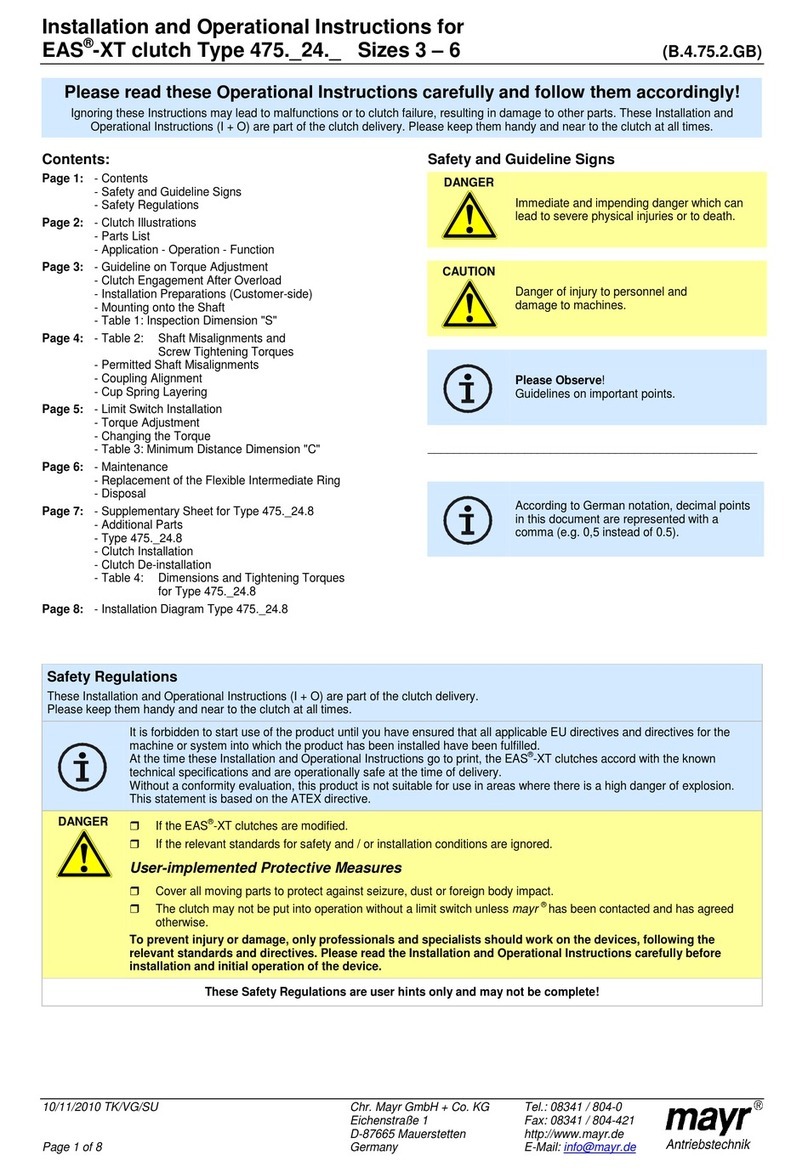

Installation and Operational Instructions for

EAS®-Compact®-R, EAS®-Compact®-RA

rustproof synchronous clutch Type 49A. _ _5._ Sizes 0 – 3 (B.4.14.5.GB)

07/03/2011 TK/GH/GF/SU Chr. Mayr GmbH + Co. KG Tel.: 08341 / 804-0

Eichenstraße 1 Fax: 08341 / 804-421

D-87665 Mauerstetten http://www.mayr.de

Page 5 of 9 Germany E-mail: info@mayr.de

Mounting onto the Shaft

EAS®-Compact® clutches include manufacturer-installed cone

bushings or keyways as part of the standard delivery.

Please observe the following when mounting cone

bushings:

Shaft tolerances

Up to diameter 38 h6 to k6

Over diameter 38 h8 to k6

Shaft surface:

finely turned or ground (Ra = 0,8 µm)

Shaft material: yield point at least 350 N/mm2,

e.g. St 60, St 70, C 45, C 60.

Degrease or remove preservation layers on the shafts and

bores before installing the clutch or the clutch hubs.

Greasy or oily bores or shafts do not transmit the

torque TRspecified on order.

Mount the clutch onto the shaft using a suitable device and

bring it into the correct axial position.

The gauge cover (Item 15, Type 49A._ 15.C) must not be

turned as otherwise the calibration will be incorrect.

Tighten the tensioning screws in steps (in 3 to max. 6

tightening sequences) and cross-wise evenly using a torque

wrench to the torque stated in Table 5.

The clutch carries out an axial movement in the

direction of the cone bushing (13) when

tightening the cone bushing (13).

De-installation on Type 49A._15._

In the cone bushing, tapped extracting holes are located next to

the tensioning screws (11 or 14).

1. Loosen all tensioning screws (11) by several thread turns.

On Type 49A._ 15.C: Screw out all tensioning screws (14)

and remove the gauge cover (15).

Please observe the position of the marking

grooves of the gauge cover (15) to the

adjusting nut (5), and keep to these positions

on re-installation.

2. Screw out the tensioning screws located next to the tapped

extracting holes and screw them into the tapped extracting

holes up to their limits.

3. Tighten the tensioning screws (11 or 14) evenly and in steps

so that the cone bushing (13) is loosened from the hub.

4. Screw the tensioning screws out of the tapped extracting

holes.

Shaft Installation via Key Connection

On the EAS®-Compact®with keyway, the clutch must be secured

axially after mounting onto the shaft, e.g. using a press cover

and a screw screwed into the shaft threaded centre hole and/or

a set screw.

The gauge cover (Item 15, Type 49A._ 25.C)

must not be turned as otherwise the calibration

will be incorrect.

Cup Spring Layering

Correct cup spring layering is a prerequisite for problem-free

clutch function and torque adjustment.

On all sizes, the lower torque range has one cup spring

(Type 49A.5_5._), the medium torque range has two cup springs

(Type 49A.6_5._) and the high torque range (not possible on

designs with cone bushing) has four cup springs (Type

49A.725._), see Fig. 6.

1x layered 2x layered 4x layered

Type 49A.515.0 Type 49A.615.0 Type 49A.725.0

Fig. 6

Torque Adjustment

In order to guarantee low-wear clutch operation, it is essential to

adjust the torque to a sufficiently high service factor (overload

torque to operating torque). Our experience has shown that an

adjustment factor of 1,3 to 3 gives good results. For very high

load changes, high accelerations and uneven operation, please

set the adjustment factor higher.

The respective torque adjustment range is printed onto the Type

tag (22). Torque adjustment is carried out by turning the

adjusting nut (5). The installed cup springs (9) are operated in

the negative range of the characteristic curve (see Fig. 9). This

means that tightening the adjusting nut (5) causes the spring

force to decrease, and loosening the adjusting nut (5) causes the

spring force to increase.

If no particular torque adjustment is requested customer-side,

the clutch will always be pre-set and marked (calibrated)

manufacturer-side to approximately 70 % of the maximum

torque.

Turning the adjusting nut (5) clockwise causes

a reduction in torque.

Turning it anti-clockwise causes an increase in

torque.

You should be facing the adjusting nut (5) as

shown in Fig. 8 and Fig. 11.

If no changes to the pre-set clutch torque are

required customer-side, the hexagon head

screws (10) must nevertheless screwed out,

painted with Loctite 243 and screwed back in

again by the customer.

It is possible to check the "Spring operation in the operating

range" (Fig. 9) using the dimension "a".

Please see Tables 2 and 3 for the respective values.

Type 49A._ _5.0:

Dimension "a" is the distance from the adjusting nut facing side

(5) to the thrust washer facing side (3), see Fig. 9, Table 2.

Type 49A._ _5.C:

Dimension "a" is the distance from the adjusting nut facing side

(5) to the sealing ring facing side (16), see Fig. 12, Table 3.