•When the season is over, always clean off any feed material and wash machine.

•Fully grease.

•Apply a covering of oil to the chains prior to storage otherwise some links may seize up while not in

use

•Have both rams in the closed positions and if any of the chrome shaft is showing put grease onto that

area. If the rams are not closed, rust spots may appear on the chrome shaft which will damage the

seals. In the closed position, the smaller ram will still have 75-80mm of shaft out. When the rams are

used regularly they are lubricated by the oil in the ram. It is when they are not used is when the

damage occurs. This applies to any rams on farm machinery.

•Check tyre pressure before you use it again.

WHEN INSPECTIONS AND ADJUSTMENTS ARE BEING MADE, HYDRAULIC

POWER MUST BE DISCONNECTED

OPERATION

SET UP

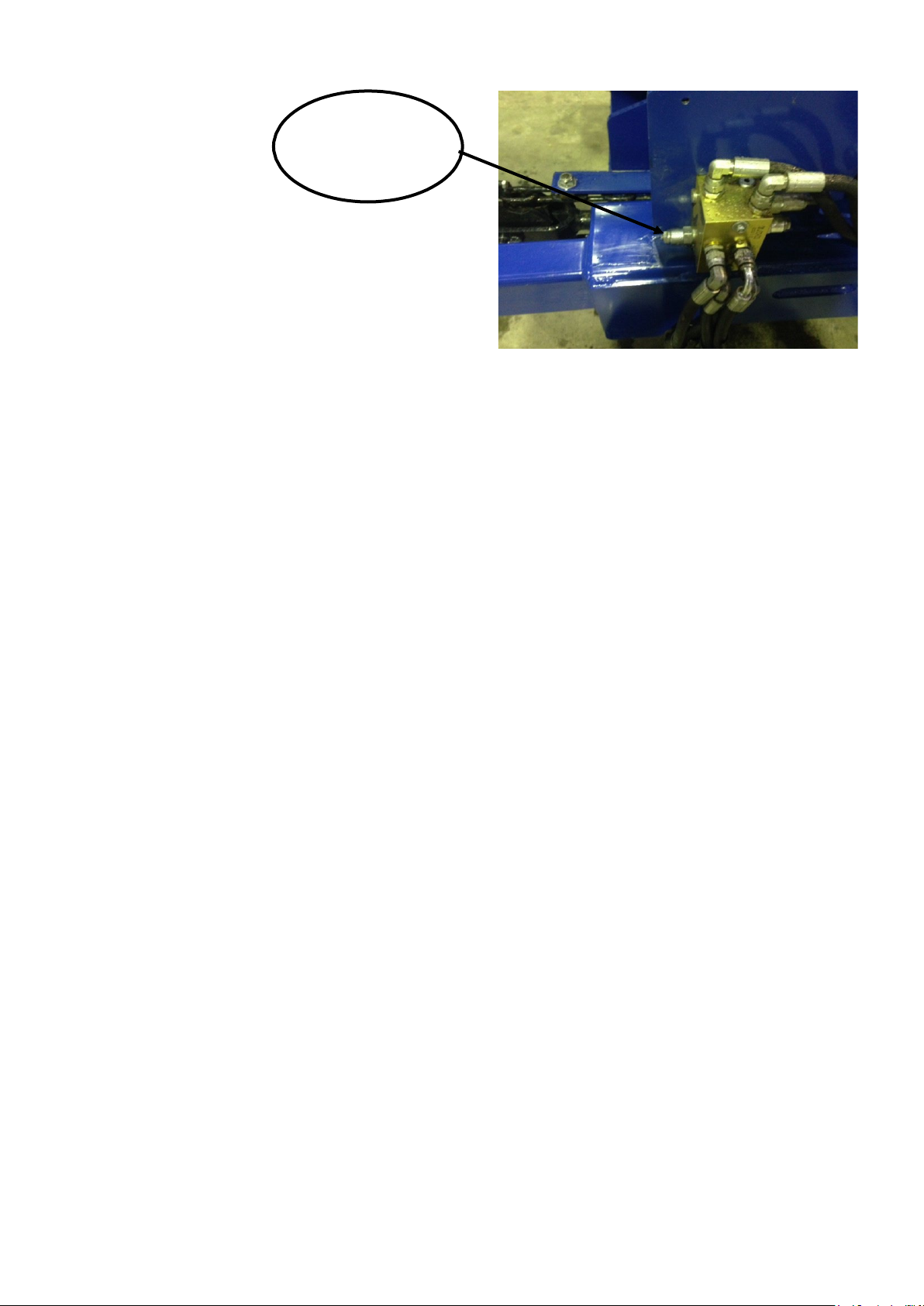

The ½ inch hoses drive the cradle and the 3/8 inch hoses operate the lifting arm.

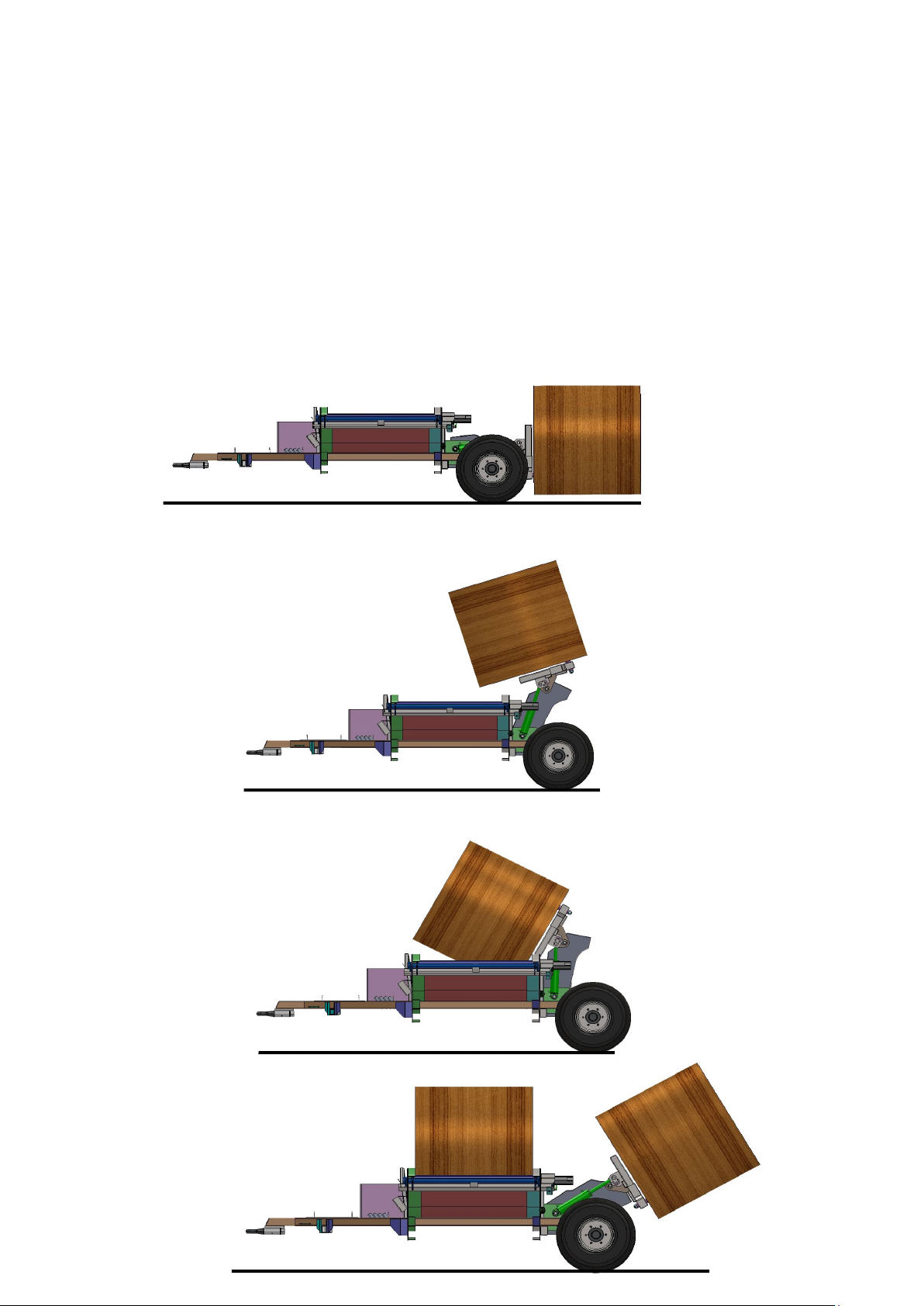

LOADING THE BALE

Lower the forks as low as they go. In this position they are set up for a standard 4 - 5 foot bale.

If feeding out 6 foot bales, lift the forks at the tyne end 100 - 150mm. Once you have loaded a few bales you

will get the right area, it does not need to be exact. If the bale is coming over and hitting the front frame, you

need to lift the forks a bit higher. If it is coming down with the back end of the bale hitting the cradle first,

then put the forks in a bit lower in the bale.

It is easier to have the two bales lined up first before loading the first bale. Once you have placed the first

bale into the cradle, you cannot see the forks when backing into the second bale so all you have to do is back

straight back into the second bale. This solves a lot of problems. Leave a gap between the bales so you can

cut the plastic off.

Before loading each bale, cut the plastic off the end of the bale, then back into it. Lift the bale over until

approximately 400mm above the cradle. This distance can vary as it depends on the bale and what height you

find it best to remove the netting. For finer chop bales you may need it higher.

You can either cut the netting underneath and pull it off or get the end of the netting and pull it off while

standing on the checker plate. Once the netting is off, you can lower the bale onto the cradle.

Another way is to cut the plastic and net off the top half of the bale, load the bale, pull out the forks, then

remove the half of the plastic and net which is the now on the top.Cut above the half way point of the bale

otherwise if may fall apart before loading on the tray.

When loading a bale, flip it right over in one movement. If you stop the bale at its full height, the second ram

may not have enough power to flip the bale over and you will have to go down and then back up. Load the

bales with the tractor idling, with a slow flow you will have more control. Once the bale is above the cradle

you will not be able to lift if up again so with the first few bales try different heights to get the net off until