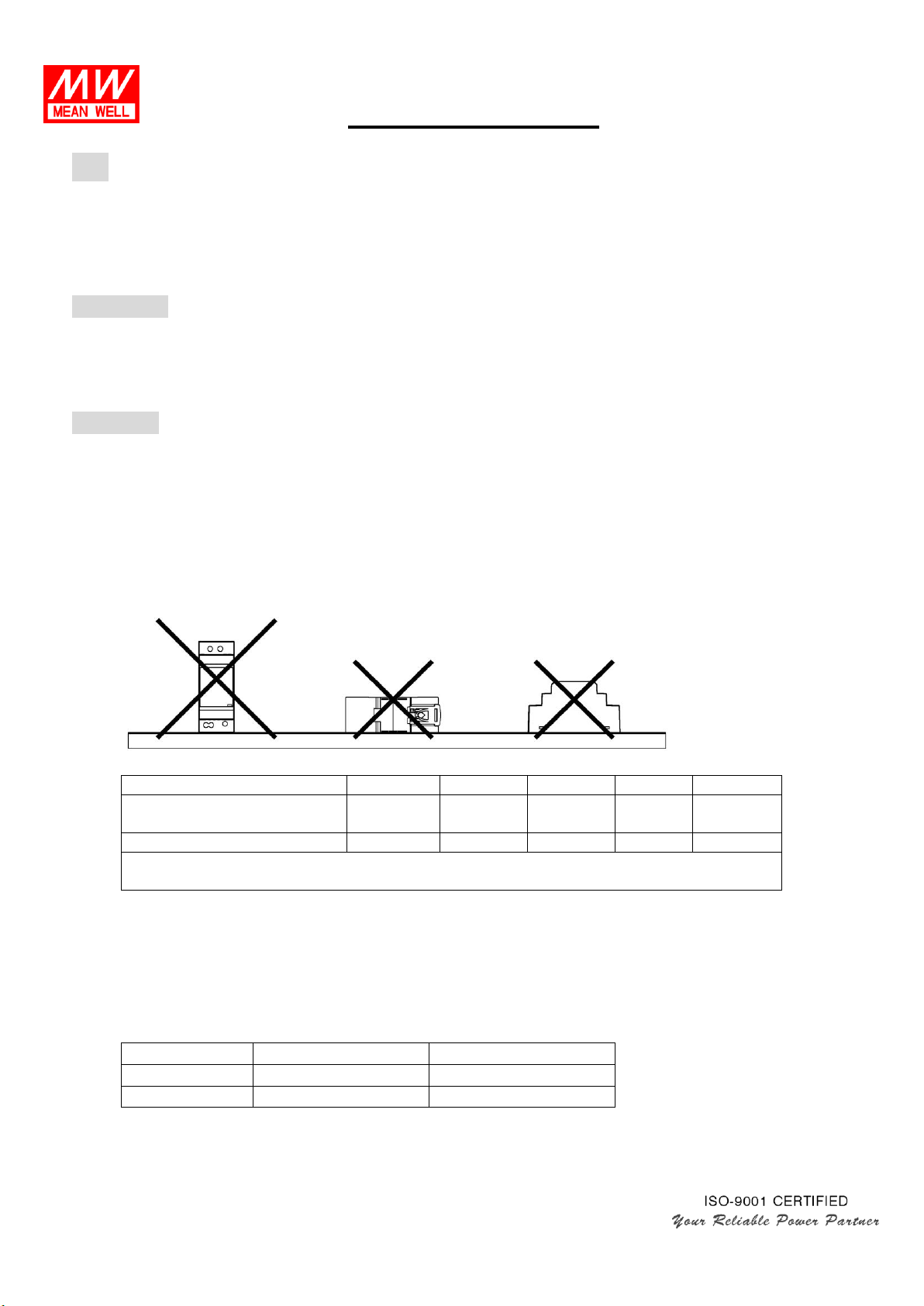

Meanwell ICL-16L Series User manual

Other Meanwell Power Supply manuals

Meanwell

Meanwell RCP-1000 Series User manual

Meanwell

Meanwell WDR Series User manual

Meanwell

Meanwell DRH-120-24 User manual

Meanwell

Meanwell DRP-3200 Series User manual

Meanwell

Meanwell AP User manual

Meanwell

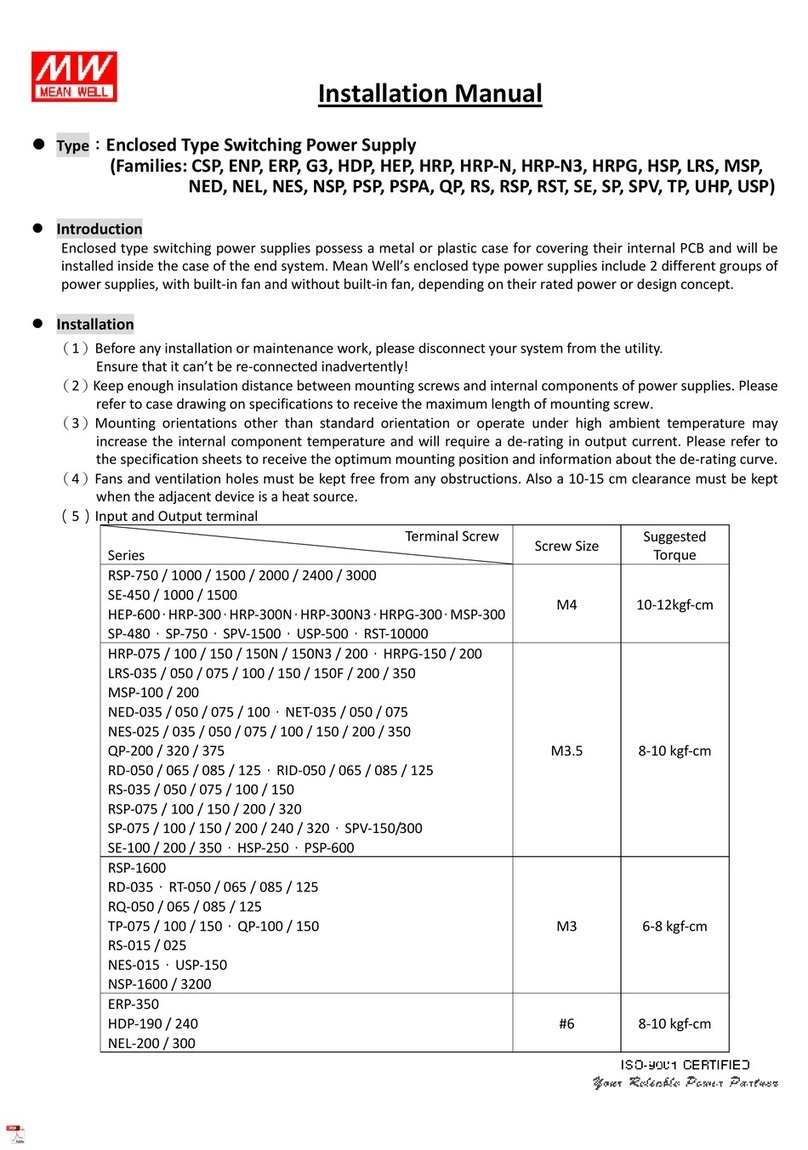

Meanwell CSP Series User manual

Meanwell

Meanwell RST-7K5-HV Series User manual

Meanwell

Meanwell LPHC-18 User manual

Meanwell

Meanwell RKP-CMU1 User manual

Meanwell

Meanwell VFD Series User manual

Meanwell

Meanwell RKP-1U User manual

Meanwell

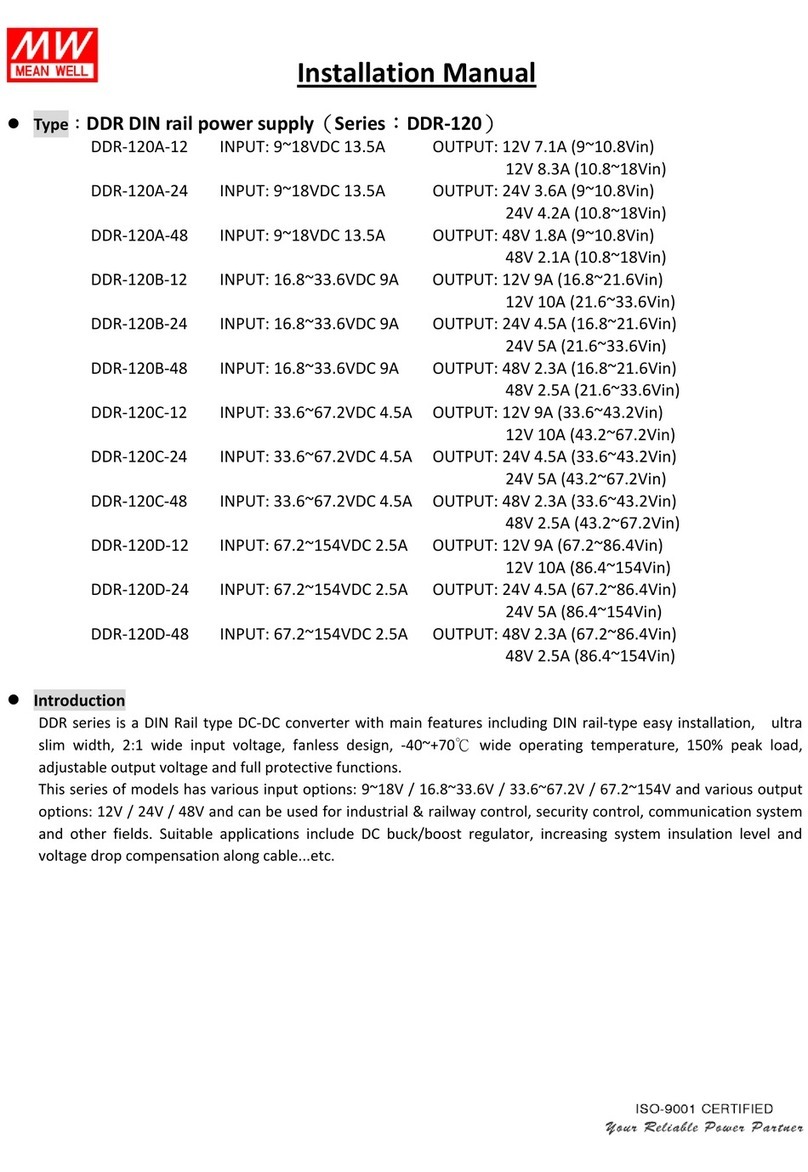

Meanwell DDR-120 Series User manual

Meanwell

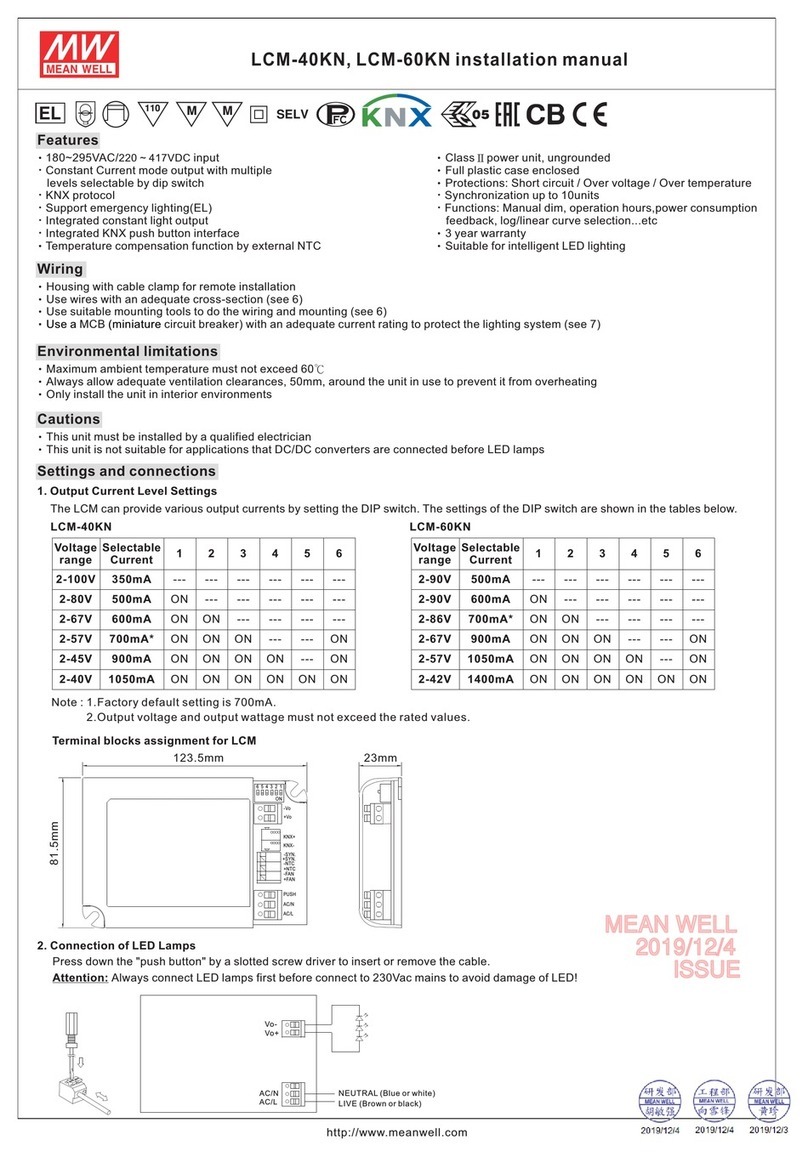

Meanwell LCM-40KN User manual

Meanwell

Meanwell DR-RDN20 User manual

Meanwell

Meanwell RCP-1600 Series User manual

Meanwell

Meanwell XLG-25 Series User manual

Meanwell

Meanwell LCM-25KM User manual

Meanwell

Meanwell HEP-2300 Series User manual

Meanwell

Meanwell PWR-40-24 User manual

Meanwell

Meanwell DRA Series User manual

Popular Power Supply manuals by other brands

ZALMAN

ZALMAN WattBit II user manual

StarTech.com

StarTech.com ATXPOWER300 instruction manual

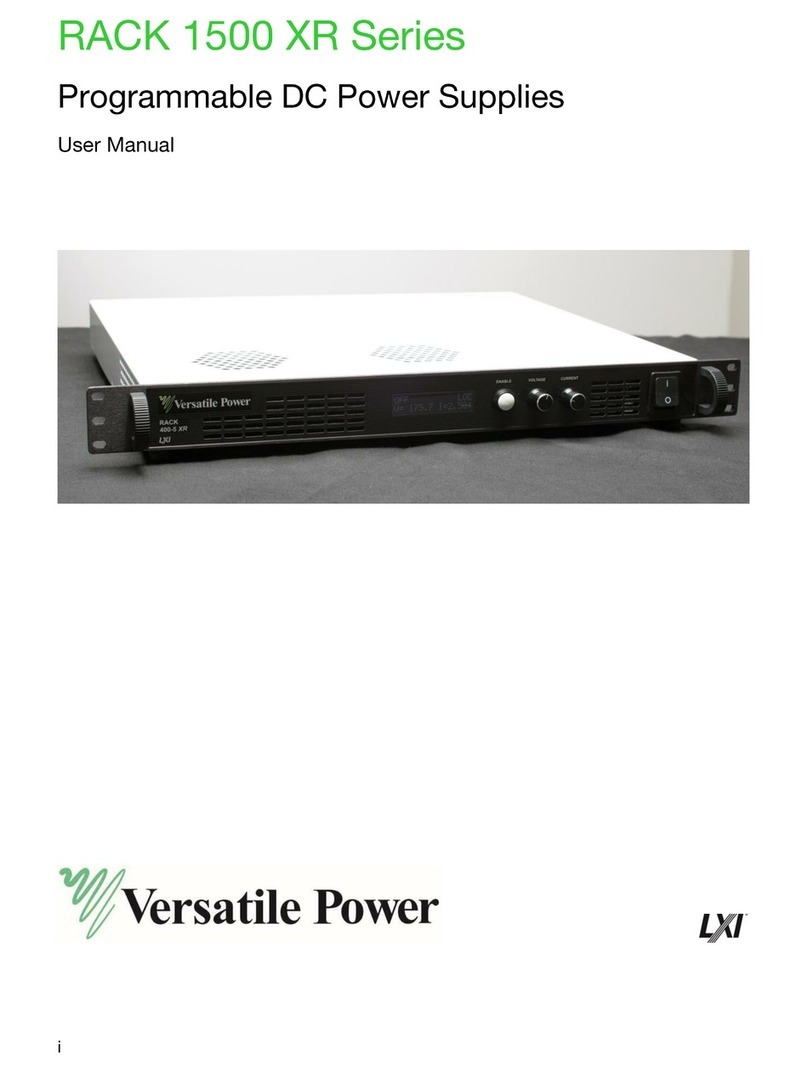

Elektro-Automatik

Elektro-Automatik PSI 9000 DT Series operating guide

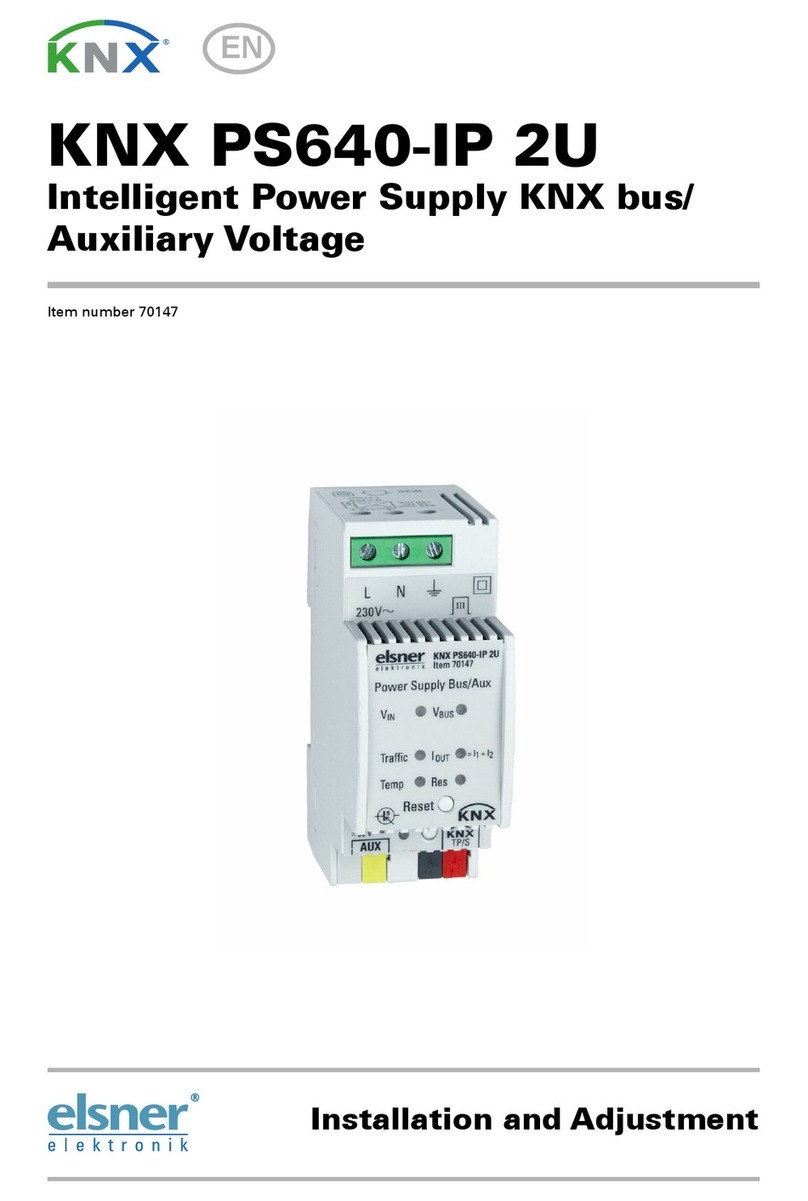

elsner elektronik

elsner elektronik KNX PS640-IP 2U Installation and adjustment

MFJ

MFJ MFJ-4275MV instruction manual

Njoy

Njoy cStation 600 user manual