Merck Milli-Q EQ 7008 User manual

SigmaAldrich.com

User Manual

Milli-Q®EQ 7008/7016

Ultrapure Water Systems

2

Table of contents

INTRODUCTION 1

System identication 1

Intended use 1

Installation component 2

Water process 5

QUICK START 8

Exit screensaver 8

Dispense pure water 8

Water quality values 9

Dispense archiving 9

View & manage Alerts and Alarms 10

Navigate the screen interface 11

Collect RO water from the tank front valve 13

CONSUMABLE MENU 14

Consumables identication with card reading 15

INFORMATION MENU 16

System 16

History 16

Flow schematic 17

SETTINGS MENU 18

Manager access (& password) 19

System conguration 20

HMI conguration 21

Accessories 22

Alarm conguration 23

Connectivity 24

Date Time & Language 24

Units 25

MAINTENANCE MENU 26

Consumable installation wizards 26

Cleaning & Sanitization 29

UV lampe 30

Depressurization 30

SELF HELP GUIDE 32

Troubleshooting tips 32

Icons 35

REQUIREMENTS AND SPECIFICATIONS 36

Water specications 36

System specications 37

Power and water consumption 39

Dimensions and weights 40

Ordering information 42

LEGAL INFORMATION & WARRANTY 44

Introduction 3

INTRODUCTION

Congratulations!

Thank you for buying a Milli-Q® water purication system.

The Milli-Q® EQ 7008/7016 water purication system produces ultrapure and pure water from a tap

water source. Installation of this product should be performed by a qualied service representative

with access to installation documentation.

This user manual is a guide to be followed during the normal operation and maintenance of a Milli-Q®

EQ 7008/7016 water purication system. It is highly recommended to fully read this manual and

comprehend its contents before using the water purication system.

System identication

System Catalogue number Production ow

rate Voltage Frequency

Milli-Q® EQ 7008

water system

(includes HMI)

ZEQ7008T0C 8 L/h 100-240 V 50/60 Hz

Milli-Q® EQ 7016

water system

(includes HMI)

ZEQ7016T0C 16 L/h 100-240 V 50/60 Hz

Manufacturing site:

Millipore SAS, 67120 Molsheim, France

For more information on your Milli-Q® system, please call your local representative or visit our website

www.sigmaaldrich.com.

Intended use

The Milli-Q® EQ 7008/7016 system is intended to produce ultrapure (type 1) and pure water from a tap

water source primarily for use in research and quality control in a variety of laboratories worldwide.

The product is designed to produce ultrapure and pure water with specic characteristics (refer to

the requirements and specications section) when it leaves the Q-POD® unit, provided that it is

fed with water quality within specications and properly maintained as required by the supplier.

We do not warrant the product for any specic application. It is up to the user to determine if

the quality of the water produced by the product matches their expectations, ts with

norms/legal requirements and to bear responsibility resulting from the usage of the water.

The product is not intended to produce: water for injection, water for dialysis, sterile water for irrigation

or injection, bacteriostatic water for injection, sterile puried water in containers, and sterile water for

injection in container or ingestion. The product is not intended to be used in explosive environments

according to ATEX Directive – equipment & protective systems intended for use in potentially explosive

atmospheres. In addition the product is not intended as a Medical Device, including In-Vitro Devices.

Introduction 4

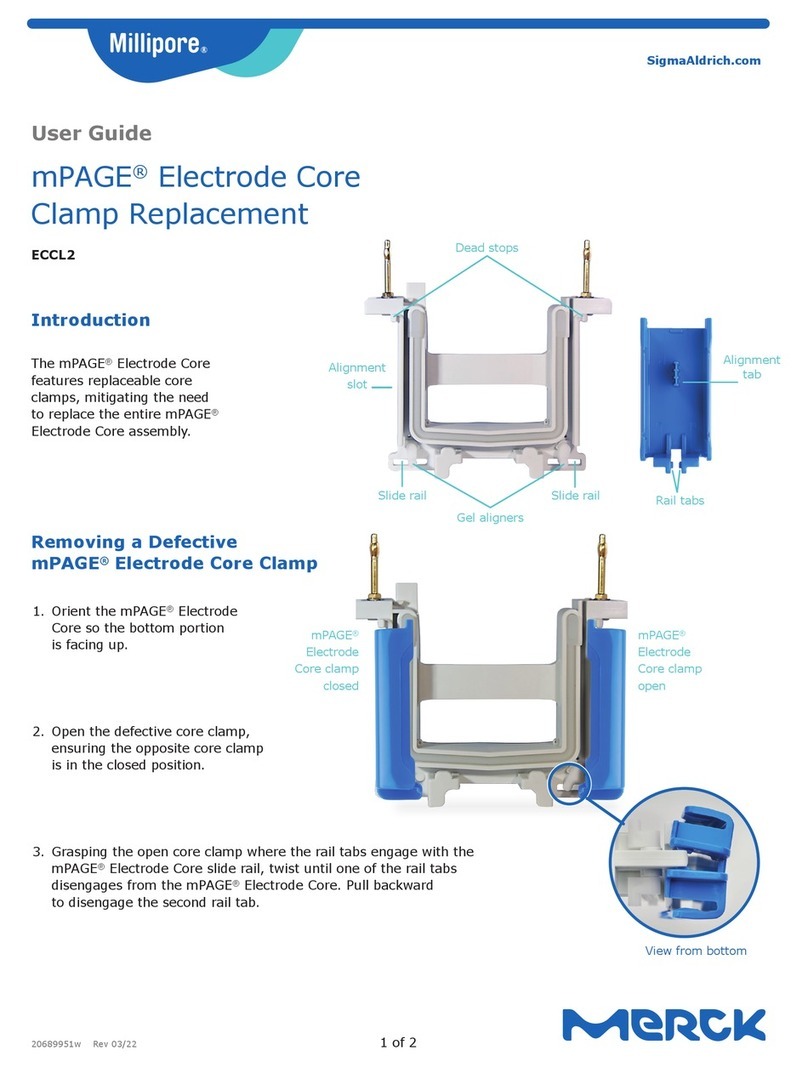

Installation components

Milli-Q® EQ 7008/7016 water system consists of at least 4 dierent components: water system

(Milli-Q® EQ 7016 on the photographs below), tank, HMI (human machine interface) display and

Q-POD® unit (Point of Dispense of ultrapure water).

1Front view of benchtop located Milli-Q®

EQ 7016 with Q-POD®unit and HMI 4Rear view of a Milli-Q® EQ 7016 system

2HMI display (bench top solution) 5Front cover

3

Front view of a wall mounted solution of

a Milli-Q® EQ 7016 water system with

Q-POD®unit and HMI

6Storage tank (50 L capacity in this ex-

ample)

1 2 3

4 5 6

Introduction 5

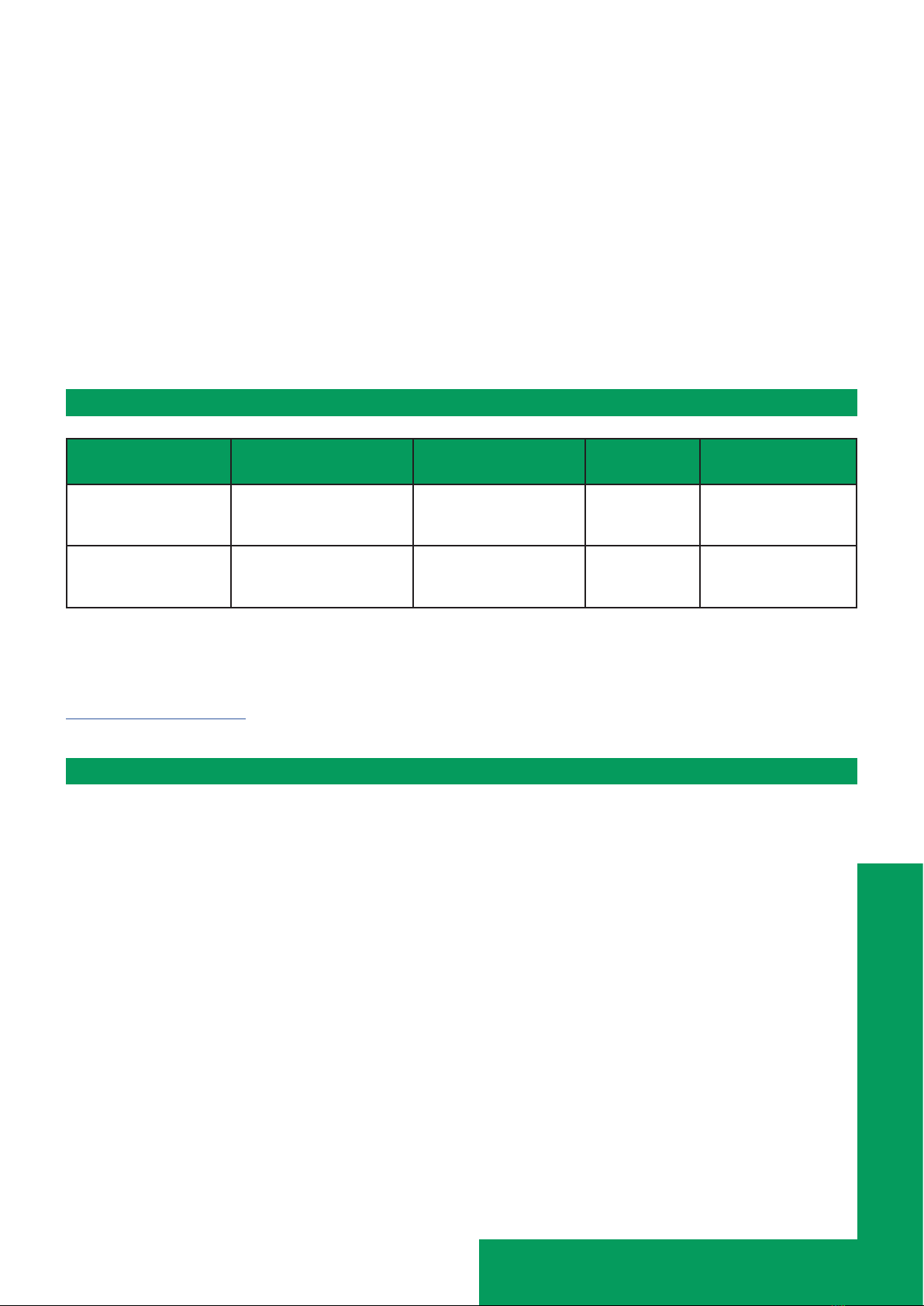

Water process

The Milli-Q® EQ 7008/7016 water system manages the production and the distribution of ultrapure

(Type 1) and pure water from a tap water source. It is composed of three dierent sections:

• Water purication unit manages the production of ultrapure water. It produces and lls the storage

tank with RO quality water.

• Storage tank stores and maintains the RO water quality.

• Point of dispense (Q-POD®unit) manages the dispensing of ultrapure water. ‘Check and Dispense’

LEDs provide information about the performance of the system.

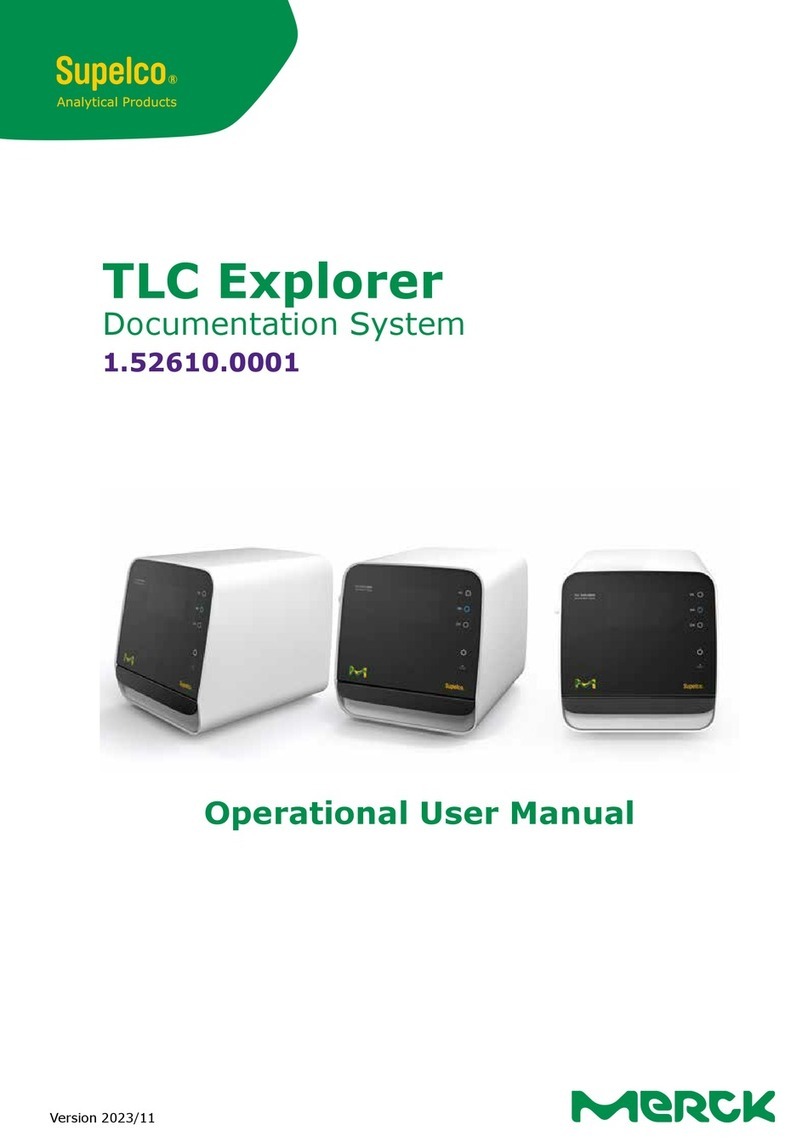

Production ow-schematic

Distribution ow-schematic

1Tap feed water 19 Storage tank (25, 50 or 100 L)

2Inlet strainer 20 Tank vent lter

3Inlet solenoid valve 21 Automatic sanitization module [OPTION]

4System feed pressure sensor 22 Distribution inlet solenoid valve

5IPAK Gard® pretreatment pack 23 Recirculation loop

6Pressure regulator 24 Distribution pump

7RO recovery loop 25 TOC indicator 3-way valve

8RO pump feed pressure sensor 26 IPAK Meta® polishing cartridge

9Reverse osmosis (RO) reject capillary 27 Strainers

10 Flow controller 28 UV lamp

11 RO ush solenoid valve 29 Intermediate thermistor

12 RO pump 30 Intermediate resistivity cell

13 Feed conductivity cell 31 IPAK Quanta® polishing cartridge

14 RO pressure sensor 32 Milli-Q® product thermistor

15 Thermistor 33 Milli-Q® product resistivity cell

16 RO membrane (1 for Milli-Q® EQ 7008 or 2 for

Milli-Q® EQ 7016 water systems) 34 Q-POD®unit

17 Permeate conductivity cell 35 Application POD-Pak

18 Permeate 3 way valve 36 Recirculation solenoid valve

1 2 3 45

6

9

812

10

11

13

14 15

16

17

7

18

19

20

19

20

22

23

24 25

26 27

27

27

28 29 30

31 32 33

34

36

35

21

21

Introduction 6

This system uses potable tap water as feed and produces ultrapure (Type 1) delivered by 1 Q-POD®

unit.

The system is divided into three sections. These are the production, the storage and the distribution.

Production: Tap water is rst puried by the IPAK Gard® pretreatment pack

which retains particles greater than 0.5 microns and removes chlorine. This helps

to prevent clogging and/or chlorine oxidation of the reverse osmosis cartridge(s).

Following the IPAK Gard® pretreatment pack, water is puried using Reverse Osmosis (RO). This is

used to remove a large percentage of ions, particles, bacteria, and large size organic molecules. The

water from this purication stage is called permeate water. This is the water that lls the storage tank.

Storage: The RO water is stored in high-quality polyethylene tank, which is equipped with

a vent lter and as a potential option with the mercury-free ech2o® automated sanitization

module (ASM) lamp. The tank vent lter maintains the consistent purity of stored water and

provides eective protection against airborne contaminants. The optional ech2o® ASM lamp

further protects the integrity of the stored water with regular exposure to bactericidal UV light.

Distribution: resistivity, TOC temperature and pressure are monitored. Tank is congured with a 2 or

5 meters connectors to the main production unit depending on the laboratory setting. The RO water

stored in the tank, is puried one step further by the IPAK Meta® polishing cartridge composed of ion-

exchange resins, removing the bulk of the ions. Water then ows to the UV oxidation lamp. Organic

molecules are partially oxidized, resulting in a release of ions. These can then be captured in the next

stage when the puried water enters the IPAK Quanta® polishing cartridge, composed of ion-exchange

resins and synthetic activated carbon. The IPAK Meta® and IPAK Quanta® polishing cartridges always

need to be replaced together to ensure optimal purication down to trace levels of contaminants.

Throughout the purication steps, quality parameters are monitored with resistivity and temperature

sensors and the TOC (total oxidizable carbon) indicator. The TOC indicator gives an indication of the

total organic content measured in ppb at the point of distribution.

The Q-POD®dispenser is detachable from its support. The dispenser uses an adjustable selector

wheel which allows dispensing of water at either a low, medium or high ow, from 0.5 to up to higher

than 1.8 L/min. At the outlet of the dispenser, the nal purication is performed by the application-

specic POD-Pak.

The large 7” touchscreen on the HMI oers a wide range of applications for users. It also has a USB

port to easily export data.

Introduction 7

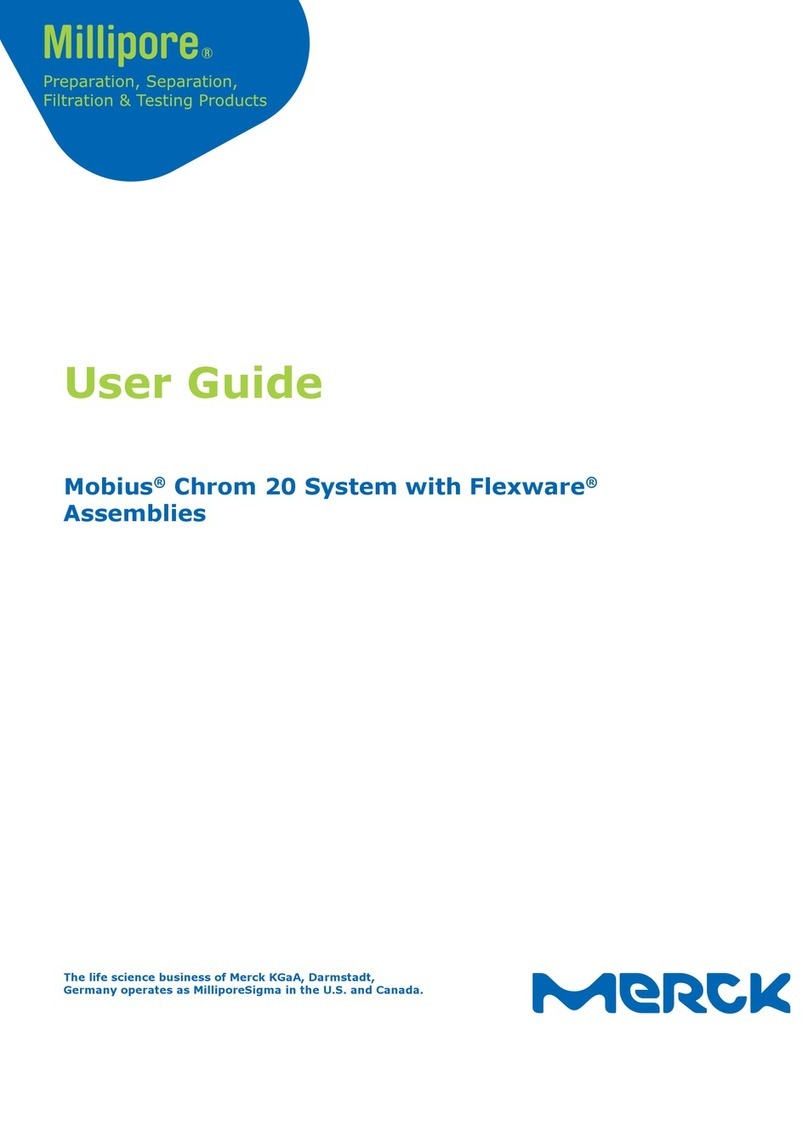

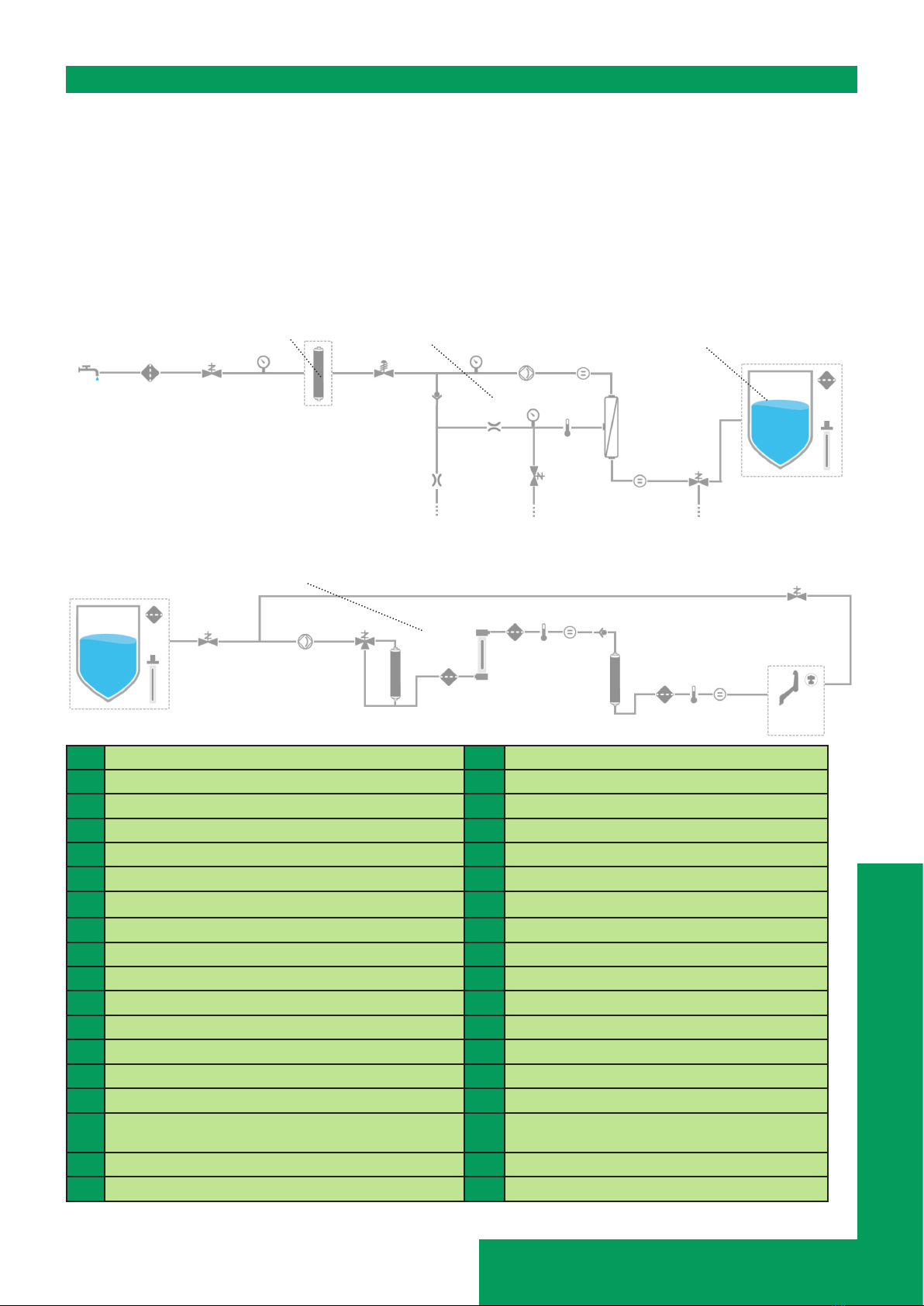

LEDs overview

On the Q-POD® unit, 3 ‘check and dispense’ LEDs indicate the dierent states of the system:

1LEDs on the Q-POD®mast 3Water Quality LED

2System Power LED 4System Alarm / Alert LED

LEDs description

LED Meaning

2

The system is powered on.

STEADY: The water quality ts the requirements (water

quality values are below alarm setpoints).

BREATHING: The system is in recirculation mode.

A water quality alarm is raised.

An alert or alarm is raised.

An alarm stop has occurred. A portion or all of the

system has stopped for safety reason.

Note:

- The 3 LEDs light up when powering the system on.

- The 3 LEDs are breathing in case of maintenance (see page 26)

1

2

3

4

Quick start 8

QUICK START (after installation performed by a qualied eld service representative)

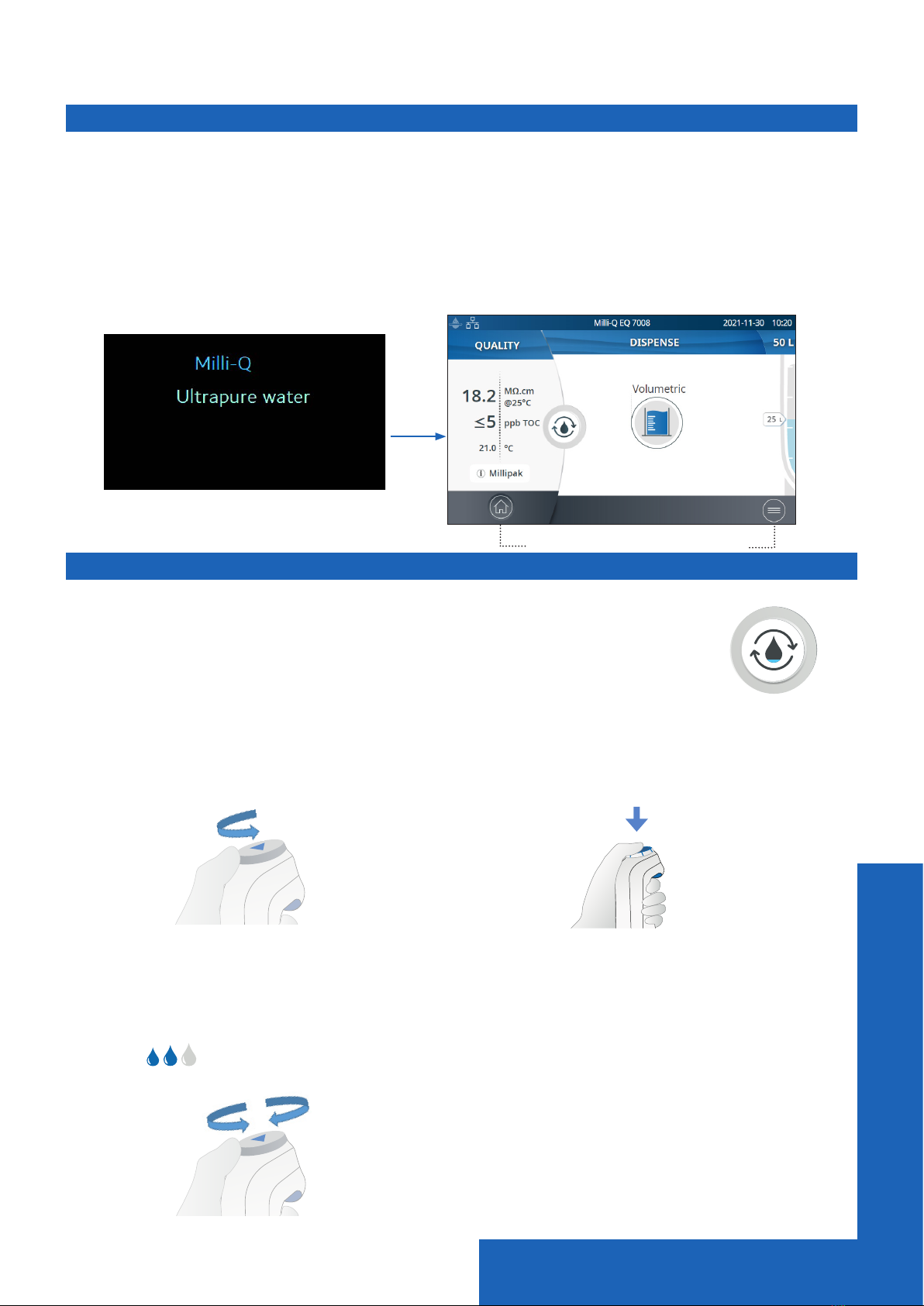

Exit screensaver

A screensaver automatically appears after a few minutes if the HMI touchscreen is not used.

Screensaver

Tap anywhere on the screen or initiate a manual dispense by pressing the dispenser wheel to exit

the screensaver.

Dispense ultrapure water

It is a good practice to recirculate water for a minute or longer before dispensing.

To do this, press on the recirculation icon,

this also refreshes the water quality parameters:

• Product resistivity

• TOC

• Temperature

There are several options to dispense ultrapure water:

Manual Dispensing

To start dispensing in low ow, turn the dis-

pense wheel one notch counter-clockwise.

To start dispensing at full ow, press down on

the dispense wheel.

Adjust owrate Stop

To increase the ow rate keep turning the

wheel counter-clockwise until full ow is

reached. To decrease the ow rate, turn the

wheel clockwise.

Low ow Full ow

To stop dispensing, press down on the wheel

or rotate the wheel clockwise until no more

water ows from the dispenser.

+

+_

Recirculate

Home screen

Status bar

Home Menu

Quick start 9

Volumetric Dispensing

Enables a user to auto dispense a pre-selected volume (10mL up to 25L using the custom value).

Note: Make sure there is enough water in the storage tank before dispensing.

The water level in the storage tank is displayed on the right side of the HMI home screen:

Select the volume to dispense, press ok to

validate. The input value can be customized,

go to page 21 Settings > System conguration

Press the Play button to start dispensing the pre-

selected volume.

The system will automatically stop once the requested volume is reached.

Water Quality values

When the dispensing is nished, the resistivity and temperature are instantly displayed on the left

side of the HMI. Ninety seconds later a new TOC value is displayed.

The green LED is lit if the water quality is within specications.

If the calculated TOC value is from 0 to

5 ppb, ≤ 5 ppb will be displayed

If the calculated TOC value is from 6 to 10 ppb,

≤ 10 ppb will be displayed

When TOC values are greater than 10 ppb, then integer values are displayed (example: 13 ppb).

Dispense archiving

After each time a dispensing is done, the water quality values are automatically archived and can be

retrieved in the history report section available in the information menu. Go to page 16 Information >

History for further information.

Quick start 10

View & manage Alerts and Alarms

Alerts give you advanced warning when maintenance is required and alarms notify you when the

system has encountered a technical issue.

Yellow LED is displayed when an alert is raised.

Red LED is displayed when an alarm is raised.

Press on the alert or the alarm

1

icon

present in the bottom bar to display the alert(s)

or/and alarm(s) which are active.

Note: The notication number indicates how many active alarms are present. When there are no

active alerts or alarms, the relevant icon disappears.

Select a specic alert or alarm to get further

information and to better understand the root

cause. Advice is provided in the information

section to help the user troubleshoot.

If the issue is not resolved and depending upon

the alert and alarm, either select the Contact tab

to nd the technical support hotline number for

further assistance or the Order tab containing

ordering information when applicable.

In order to protect the system and user

applications, alarms of a serious nature will

automatically stop the system from dispensing

water.

Note: These are displayed on the screensaver to

tell the user when the system is not in active use

Alerts provide advanced warning of any

maintenance actions that will be required. Press

Close to cancel the alert for 24 hours. Press Start

on the HMI in order to begin a series of steps

which will clear the alert for a long time.

An Order tab appears when an alert is caused by

a consumable needing replacement soon. The

Order tab contains catalogue numbers of the

consumable(s).

Quick start 11

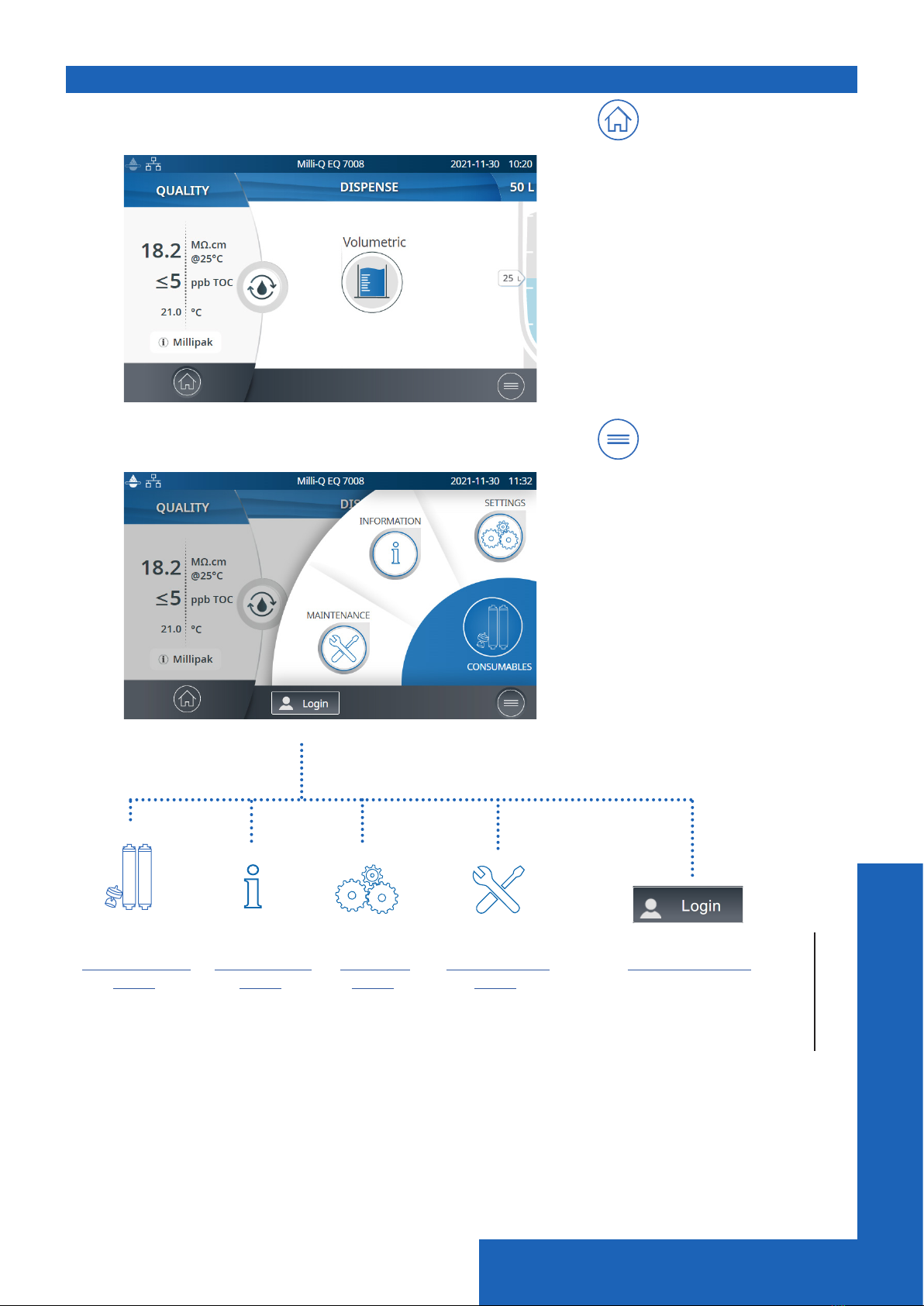

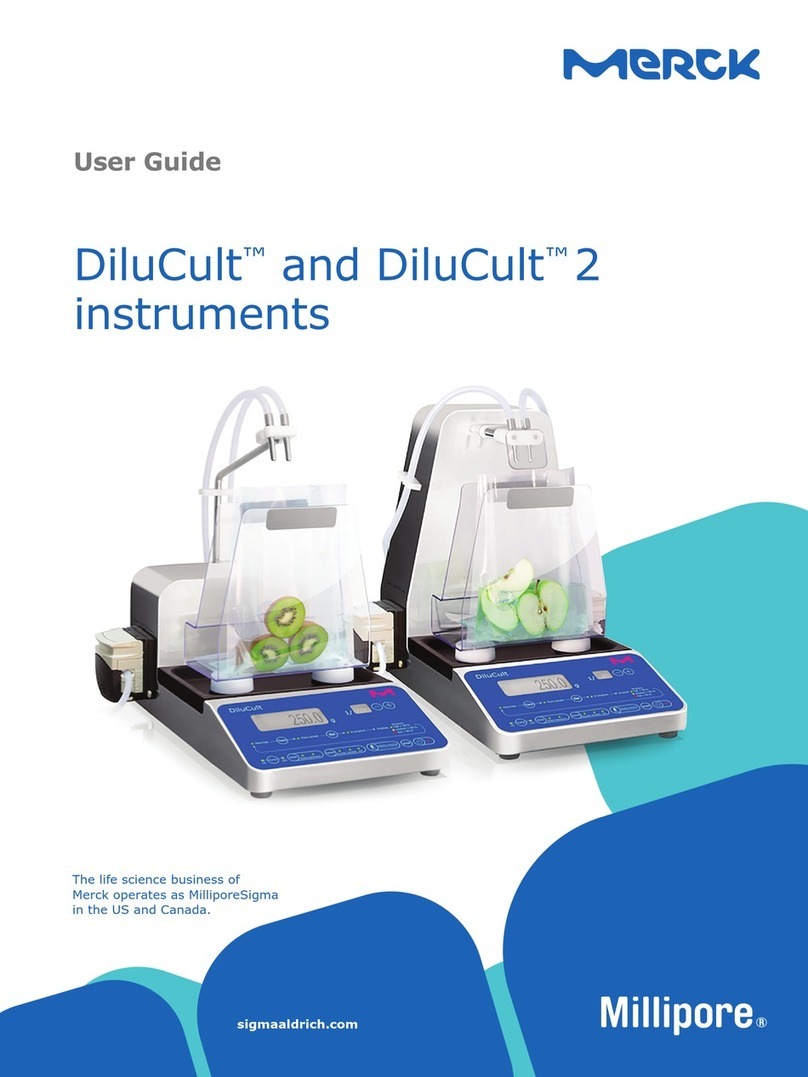

Navigate the screen interface

HOME SCREEN

Home

- Water quality information

- Dispensing functions

- Alerts & Alarms

(when generated by the system)

- Water level in tank

- Recirculation start icon

MAIN MENUS Menu

- Settings

- Information

- Maintenance

- Consumables

- Login

Go to

Consumables

Menu

Go to

Information

Menu

Go to

Settings

Menu

Go to

Maintenance

Menu

Go to

Manager access

Quick start 12

Apps

When there

are multiple

lines, a

scroll bar

is present

to swipe up

and down

Indicates how many screens are present and where you are.

Swipe left & right anywhere on screen to switch between screens.

Pops-up screens

When a text box is selected, the keypad will

automatically appear.

To remove the keypad click on or on any

zone outside the keypad.

Note: When in a menu or app level screen, the system automatically goes to the home screen after

1 minute of inactivity.

When a pop-up type of screen is displayed, the system does not automatically return to the home

screen after 1 minute of inactivity.

Quick start 13

Collect RO water from the tank front valve

Follow the steps below to collect RO water from the front of the tank.

1. Clean the tank front valve : use a lint free cloth towel, wet it with the cleaning agent and wipe

down all exposed exterior surfaces of the valve. Cleaning agents that can be used include :

- KLERCIDE™ Isopropanol 70% or equivalent composition

- SPOR-KLENZ® (Ready to use) or equivalent composition

Be sure to follow the safety precautions listed with the recommended cleaning agent.

2. Open the front valve and discard the rst liter of water dispensed from the tank front valve.

3. Open the front valve to dispense water for your needs.

4. Close the front tank valve.

5. Clean the front tank valve again using one of the cleaning agents listed above.

Consumable Menu 14

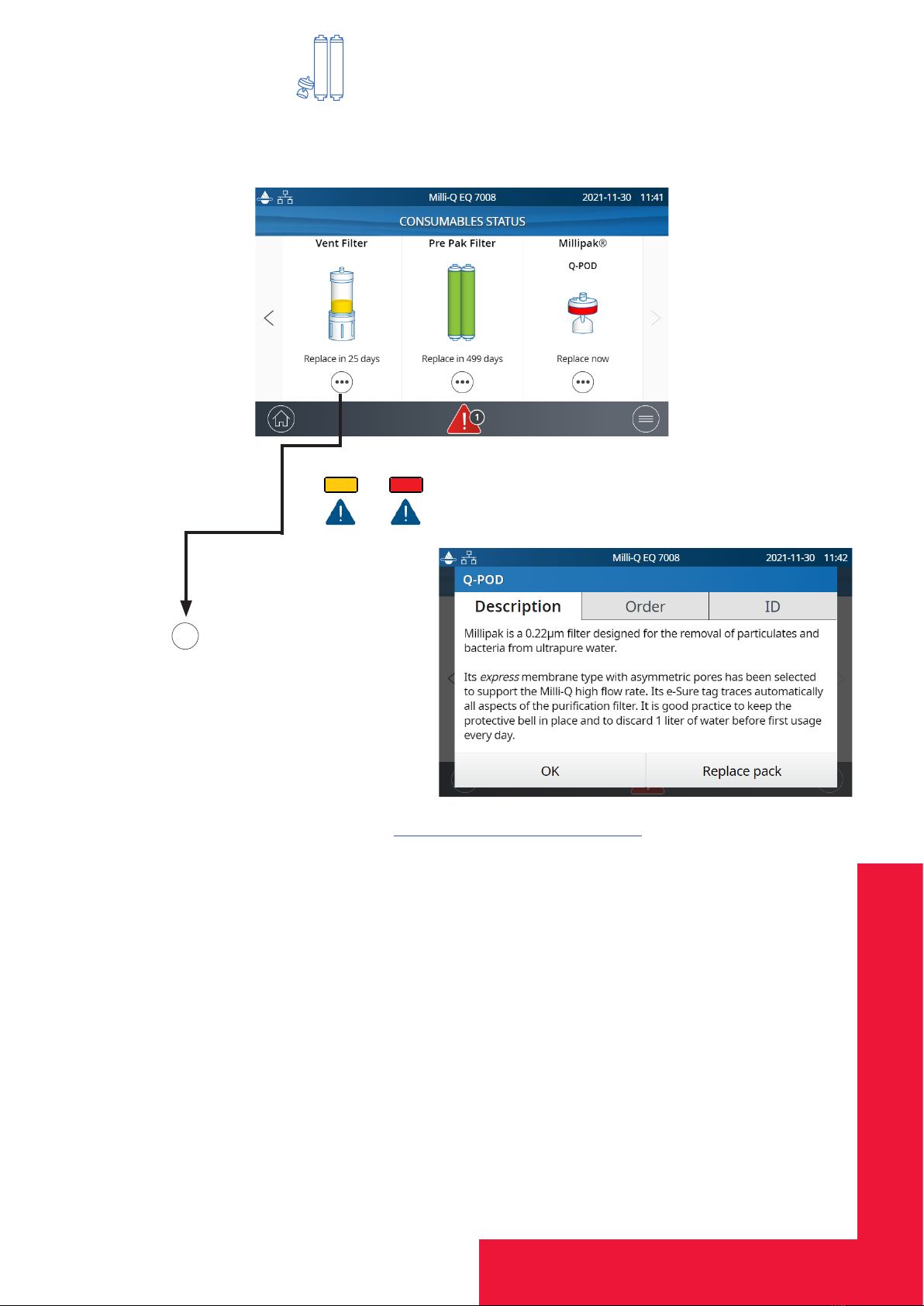

CONSUMABLE MENU

Viewing Consumables Status

By using dierent colors, the status of installed consumables are indicated.

LEDs

Green:no action required

Yellow: notice for a maintenance action

Red: maintenance required!

Press on the

•••

icon to get a description of

the consumable, the ordering information,

and the consumable’s ID.

Certicates of quality are available online www.mymilliqconsumables.com

All cartridges have been designed to be easily replaced by a user. A shortcut to access to the re-

placement wizard is available by clicking on the “Replace pack” button in the pop-up.

Note: In case of application of PrePak lter pretreatment pack (PRPK00001 or PRPK000A1), it is rec-

ommended to replace the PrePak at the same time as the IPAK Gard® pretreatment pack.

Consumable Menu 15

Consumables identication with card reading

For each consumable, the following pieces of information are available:

• lot number

• catalog number

• installation date

The IPAK Quanta®and Meta® polishing cartridges, IPAK Gard® pretreatment pack and application

POD-Paks information is automatically registered during their installation.

The tank vent lter comes with a RFID card enabling the transfer of the data into the system. Go to

page 26 Maintenance>Consumables installation wizard for further information.

Information 16

INFORMATION MENU

This menu provides system information and system status. Dispensing is available while in this

menu.

Available apps:

System

Find system details

Select System ID to nd the information on the

water system model and installation details.

History

2 user reports exist:

• Daily quality measures report

Each row represents a day (midnight to midnight) and is dated. It contains daily averages for

product resistivity, TOC and temperature dispensed each day. Also included is the total volume

dispensed during the day.

• Dispensing events report

Each row contains a record of a single dispensing. It is an archive of all the dispense reports.

To export data or preview a graph:

1. Select a time period of interest with a start

and end date.

2. A graph pre-view of the last 30 records is

available on the HMI screen.

3. Export the report in .ods (open document

source) format to visualize the full data and in-

tegrate them into a data management system.

Note: A complete history report with all system activity is available. By default it is only

available when logged-in as the system manager. This can be modied by de-activating

the system manager prole in the settings menu, go to page 19 Settings>Manager access.

System History Troubleshooting

Contacts Flow schematic

Information 17

Flow schematics

Flow schematics are graphic representations of the hydraulic components of the water purication

system. Components change color depending on the state and system status.

Grey - inactive Blue - active

Yellow - maintenance alert Red - sensor error or consumable replacement overdue alarm

Troubleshooting

Used to access a diagnostic summary.

Open this app to get information which can be communicated with a technical service representative

in case of troubleshooting.

• System information & last service visit

• Water quality & consumables (installed dates)

• Active alerts, alarms & auto-test results

• Diagnostics

Contacts

To edit contact information, login as the system manager, go to page 19 Settings>Manager access.

The user parameters are used on various reports generated by the system and can quickly help users

identify the right contact for any questions or issues.

Internal contact

Technical support

Responsible for system conguration & quality settings

In case of troubleshooting

Production ow schematic shows all

components and operating values used to

produce RO quality water and to store it.

Distribution ow schematic shows all

components and values used to purify RO

quality water from the storage tank into

ultrapure water that is dispensed

Settings 18

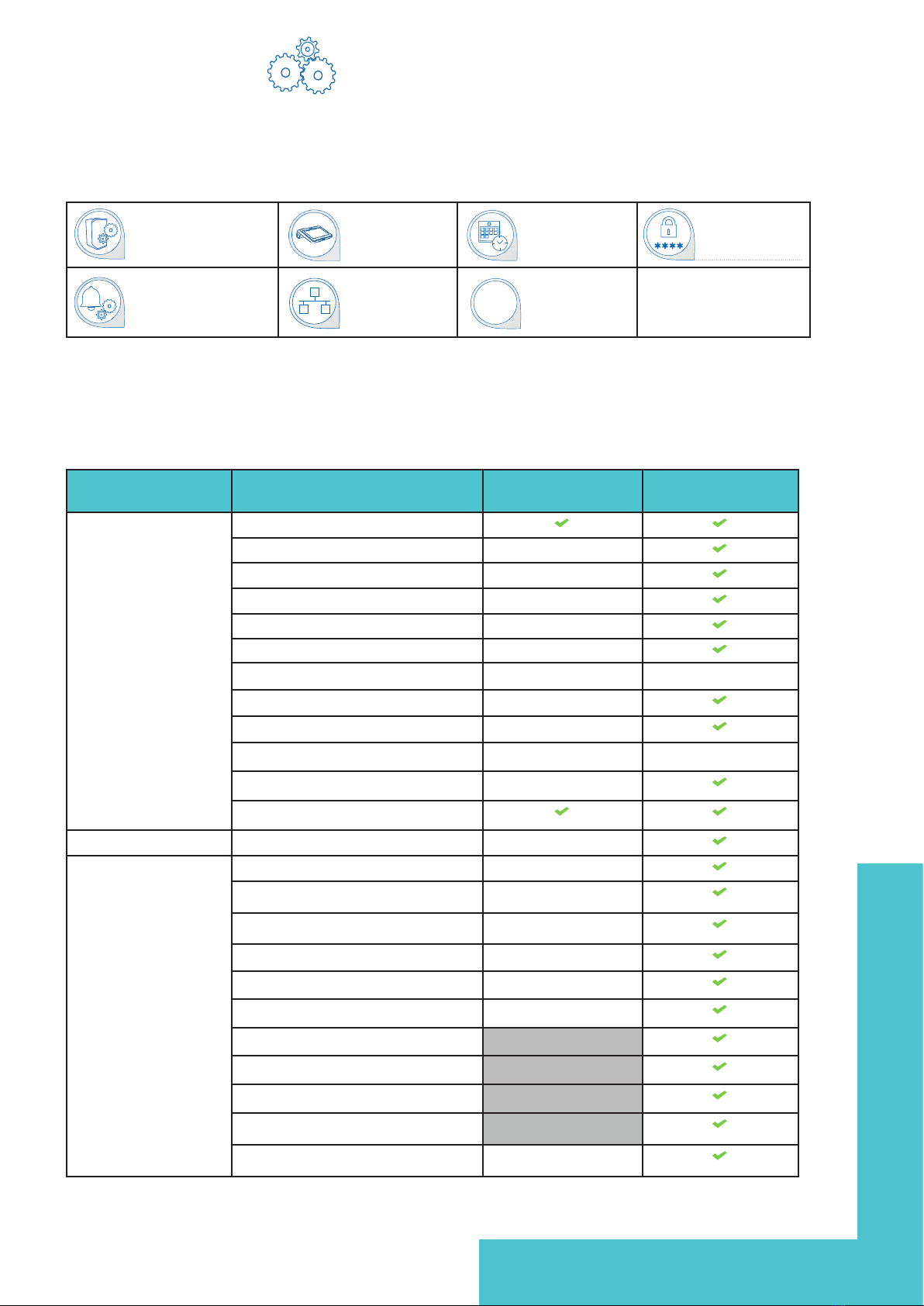

SETTINGS MENU

Dierent settings are available to customize the water purication system operation. Depending on

the user prole (end-user operator / system manager) some of the settings will have either read-

only or read & write access.

Available apps:

°C / °F

Note: Dispensing while in this menu is not available.

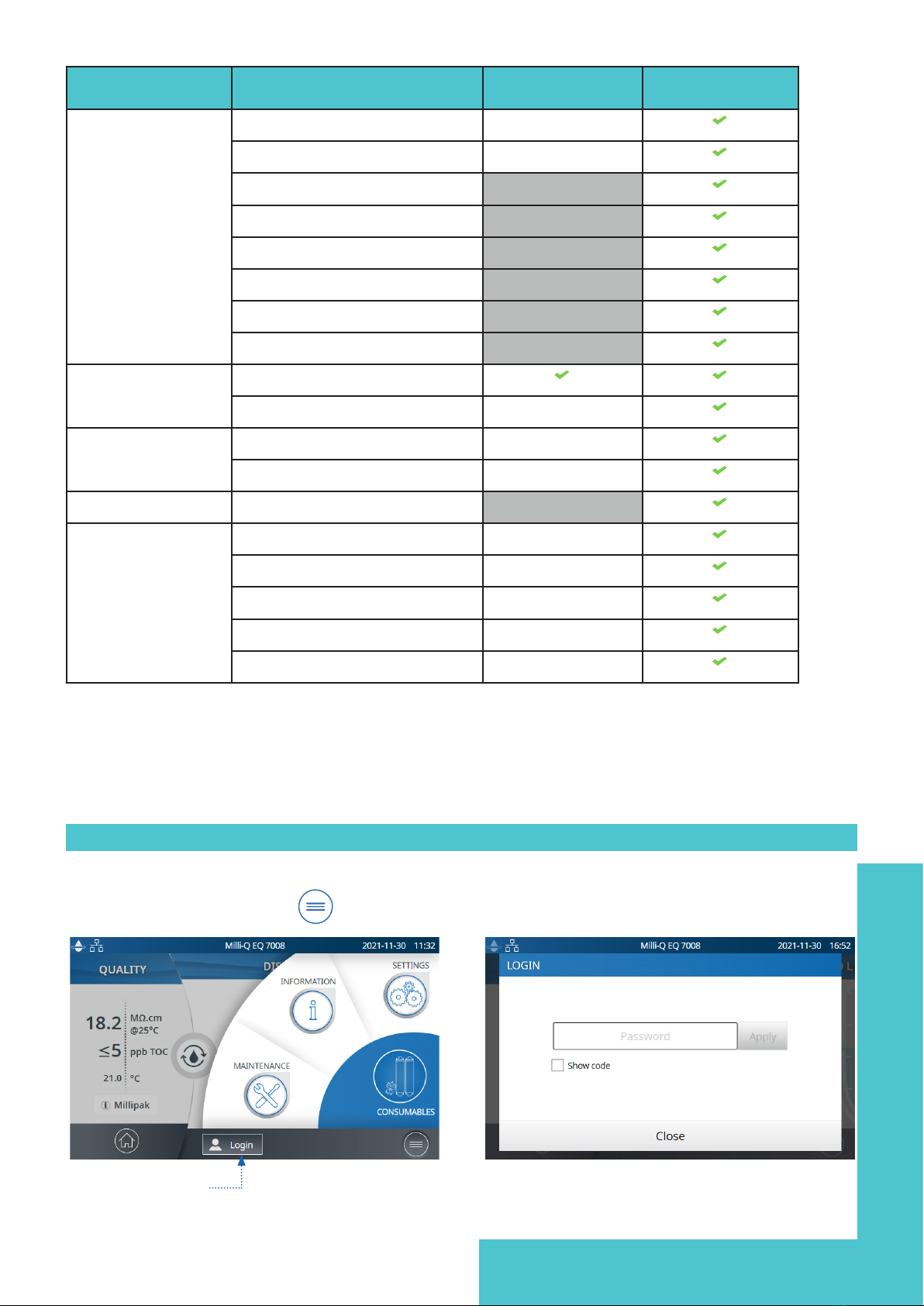

Settings End-user System

Manager

System

Conguration

Lab close

Screen saver Read only

Water sensor Read only

Alarm relay Read only

Foot pedal Read only

Periodic RO ush check time Read only

Tank capacity Read only Read only

Tank rell setpoint Read only

ech2o ASM lamp Read only

Recirculation duration Read only Read only

Safety ow stop Read only

Custom volume

Connectivity Local network Read only

Alarm conguration Permeate conductivity Read only

RO ionic rejection Read only

RO feed conductivity RO high Read only

RO feed conductivity tap high Read only

Inlet strainer clean Read only

Cl2 clean Read only

Pre Pak lter

IPAK Gard (lifetime)

IPAK Gard (volume)

Vent lter

Tank empty Read only

System

Conguration

HMI congu-

ration

Date, Time &

Language Password

Alarm

Conguration Connectivity Units

The table below shows the list of settings. A green tick mark symbol means that the setting can be

modied.

Settings 19

Settings End-user System

Manager

Alarm conguration Ultrapure resistivity Read only

Ultrapure TOC Read only

IPAK polishing cartridges

Millipak

Millipak Gold

LC-pak

VOC-pak

EDS-pak

HMI

conguration

Brightness

Buzzer Read only

Date, Time & Lan-

guage

Time zone - Date - Time Read only

Language Read only

Password System manager

Units Resistivity / Conductivity Read only

Temperature Read only

Storage tank Read only

Temperature compensation mode Read only

Pressure Read only

Manager access (& password)

Login as a Manager

1. Press on the menu button from the Home page.

2. Press on Login.

Settings 20

3. Enter system manager password.

To display & see the password while typing, select the Show code checkbox.

Once logged-in, the manager icon is displayed in the top left corner.

If a manual logout is not performed, the system manager prole will be automatically logged out

after 1 hour of inactivity.

Note: By default the Manager password is active. The default password is PASS

Log out as a Manager

1. Press on the menu button .

2. Press on Logout.

Modify system manager settings

This can only be done when logged-in as a

manager.

In the Password app:

1. Deactivate/re-activate the manager password

through the password activation slider button.

2. If required, change the password.

Note: Contact your technical service

representative if the password is lost or forgotten.

Important! Deactivating the system manager prole will allow any user to have read & write access

with all settings.

System conguration

Lab close

If the water system is not going to be used for more than 3 continuous days, then the Lab Close mode

can be activated in order to save energy. Before starting this mode, the tank is manually emptied.

During this mode, periodic recirculation occurs once a day instead of once per hour. A few hours

before the completion of this mode, the tank is automatically relled.

Follow the self-guided wizard to activate the lab close. It is important to realise that it can take a long

time to manually empty the tank before starting a lab close mode. The time it takes depends upon

the capacity and volume of water within the tank. It may take up to 1 hour for a 100 L tank.

In case of multi system conguration with one tank:

• If 1 Milli-Q® EQ 7000 water system is connected to 1/2 Milli-Q® EQ 7008/7016 water system(s), lab

close mode shall only be toggled on Milli-Q® EQ 7000 water system (ASM highly recommended).

In case of quality alarm/alert upon lab reopening, simply empty the tank through POD dispensing.

• If the multi system conguration is composed of 2 Milli-Q® EQ 7008/7016 water systems, both lab

close wizards shall be activated simulateanously on both systems step by step.

This manual suits for next models

1

Table of contents

Other Merck Laboratory Equipment manuals

Merck

Merck Millipore Milliflex User manual

Merck

Merck Millipore ReadyStream User manual

Merck

Merck Millipore CellASIC ONIX2 User manual

Merck

Merck DiluCult User manual

Merck

Merck Millipore Auto2D User manual

Merck

Merck Millipore Scepter 3.0 Installation guide

Merck

Merck Pellicon Capsule User manual

Merck

Merck APC SmartTouch User manual

Merck

Merck Millipore DiluCult User manual

Merck

Merck Millipore Auto2D Plus User manual