1

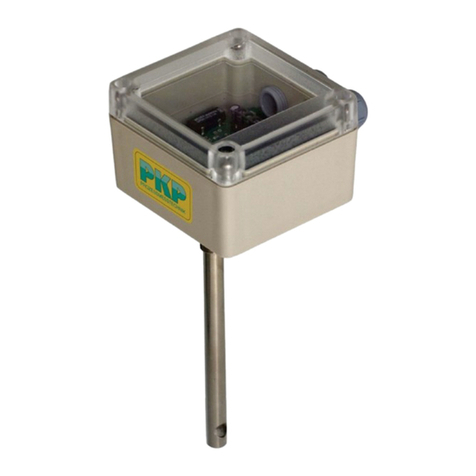

Flow data sensor ZE 3000

micro-processor controlled for accurate flow

measurement and evaluation

330501 - 05/06

Product description

The ZE3000 emits a 4..20 mA signal according to

industrial standards, generated in the DS15 by the

precise magnet angle detection of the magnetic

float.

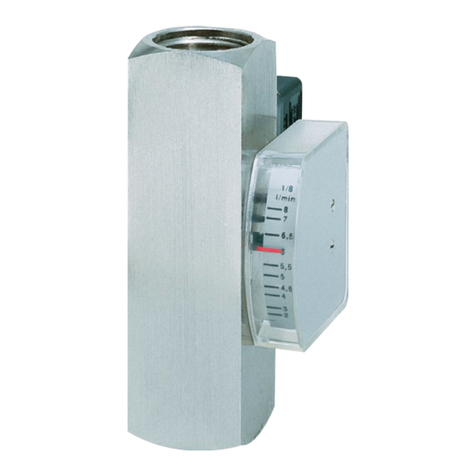

Existing flowmeters (with magnetic floats) can be

easily retrofitted with the ZE3000 to electrically

signal the flow and, for instance, to further process

the values in a PLC for process control or to directly

display the flow rate.

This micro-processor controlled unit is programmed

for the DS15 concerned! This guarantees accurate

flow measurement and evaluation.

IMPORTANT: The DS15 to which the ZE3000 is to be

fitted must be known in advance!

Features:

• 2-wire technology

• 4..20mA analog output

• 8..28VDC input

• Individual programming adapted to the DFM

• 11 point calibration

• non-volatile value storage

• 0 button to compensate for the surrounding

magnetic influences

• Factory setting of the lower limit value (low-cutoff)

0..99% according to customer’s specifications

• Factory settable time lag (low-pass-filter)

0.1...2.5 sec according to customer’s specifications

• Measuring accuracy better than 0.5%

Pin 1: 8..28VDC

Pin 2: GND

Installation

Screw clamps are used to fit the ZE3000 on the

dovetail guide of the flowmeter. The plug connector

is located in the upper section.

During installation, ensure that the notch of the

ZE3000 coincides with the 50% mark on the DFM

scale.

Following this, proceed with the wiring according to

the plug assignment plan.

Plug assignment

Start-up

Once installed and the voltage is applied, press the

0 button for at least 2 sec to compensate for

surrounding magnetic influences.

During this phase ensure that the float is in its

bottom position, i.e. no flow must take place!