5. Operation

5.1 Safety

5.1.1 Safety measures

The importance of following safety procedures in the operation of industrial meat grinders

cannot be over-stressed. Meat grinders are capable of inflicting bodily damage to operators.

However by using common sense and being careful, as well as following all safety measures in

the operation of meat grinders, the operator will get the best possible performance out of this

versatile machine, and minimize the of accidents.

Your personal safety is more important than the quick operation of the machine.

It is recommended that only authorized persons who have received the correct training in the

operation of industrial band saws may operate them. They must also be aware of the danger

factors and safety measures.

PLEASE NOTE

All safety instructions in this manual are the manufacturer's recommended practices. Local safety

regulations and measures must always be observed.

Do not use this machine to anything else, than the purposes mentioned in this manual. The

diameter of the holes in the last plate towards the outlet shall be less than 8 mm. It is

forbidden to use hole plates with larger holes. The last plate towards the outlet is not

allowed to be ground thinner than 5 mm thickness.

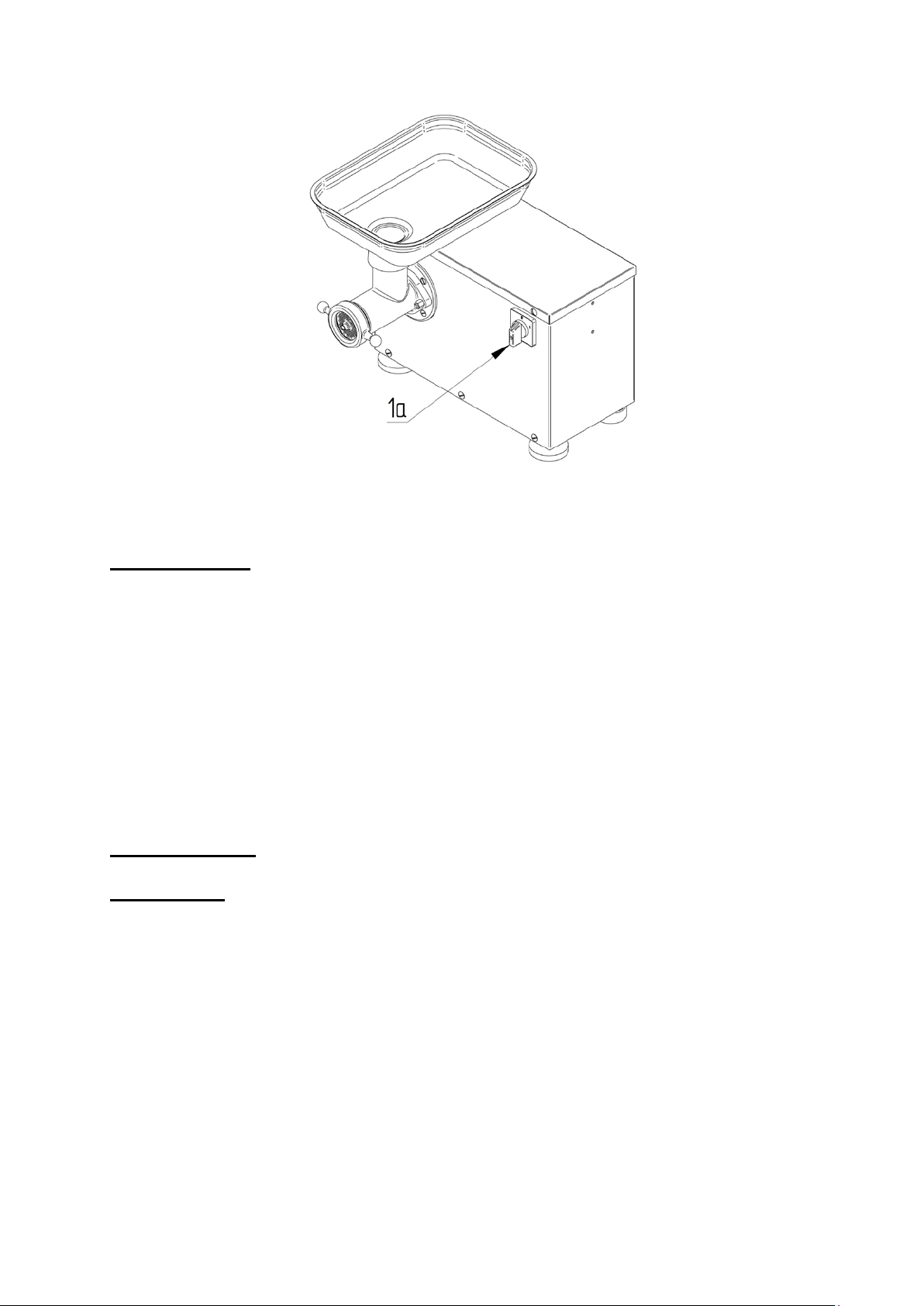

5.1.2 Before use

Before starting up the meat grinder, the operator must:

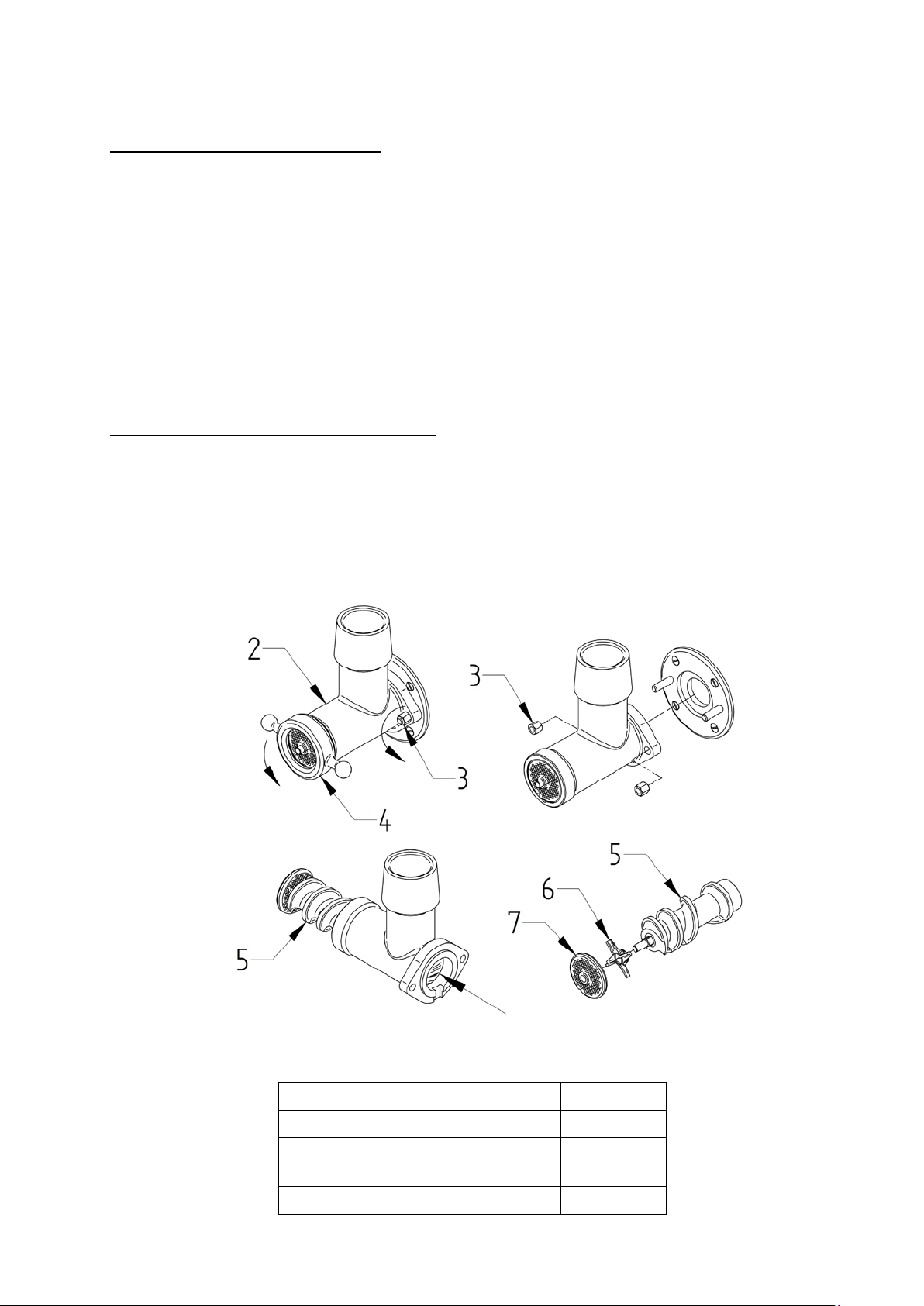

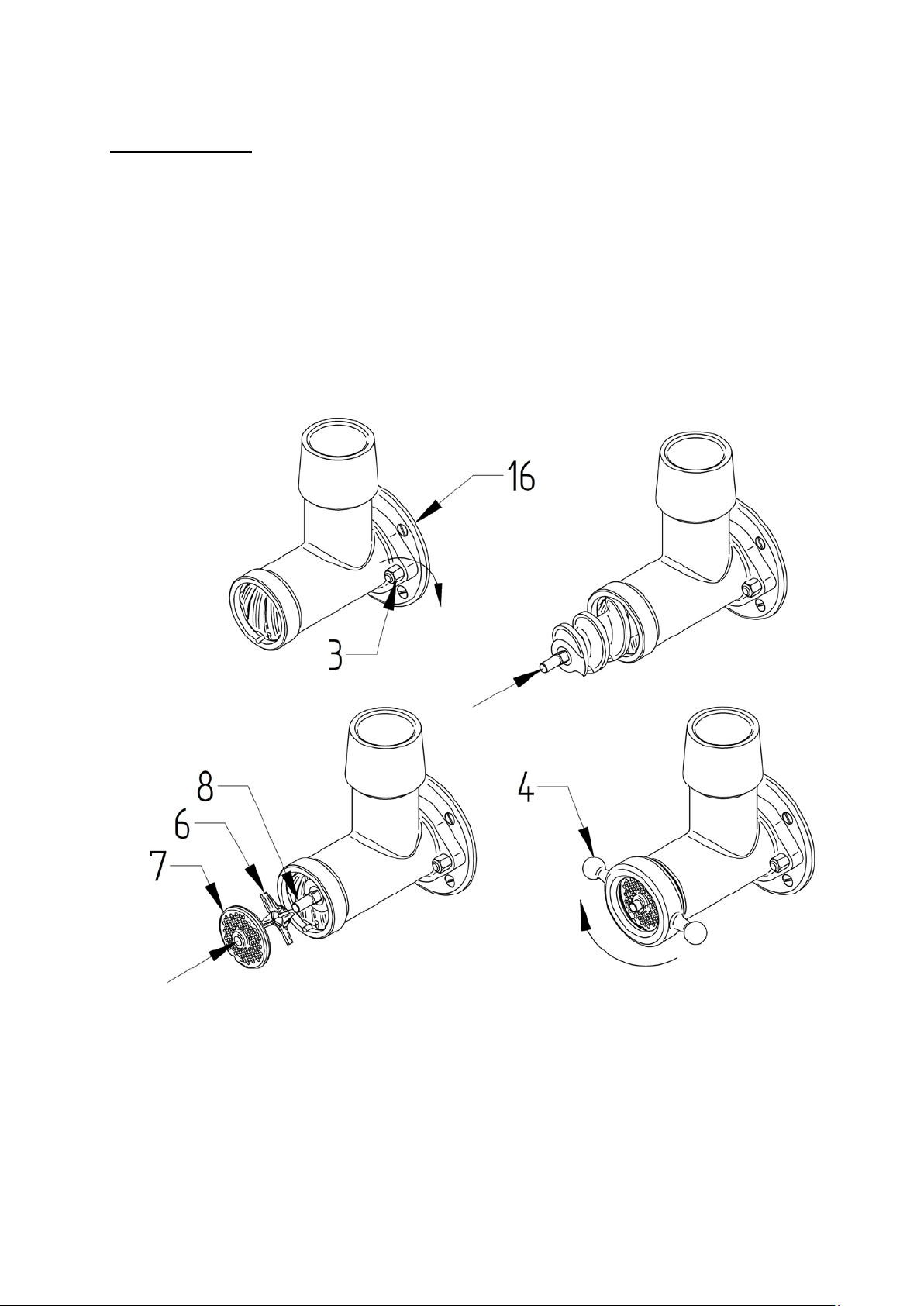

1. DISMANTLE the blades and feeding screw (Instructions for cleaning: chapter 6)

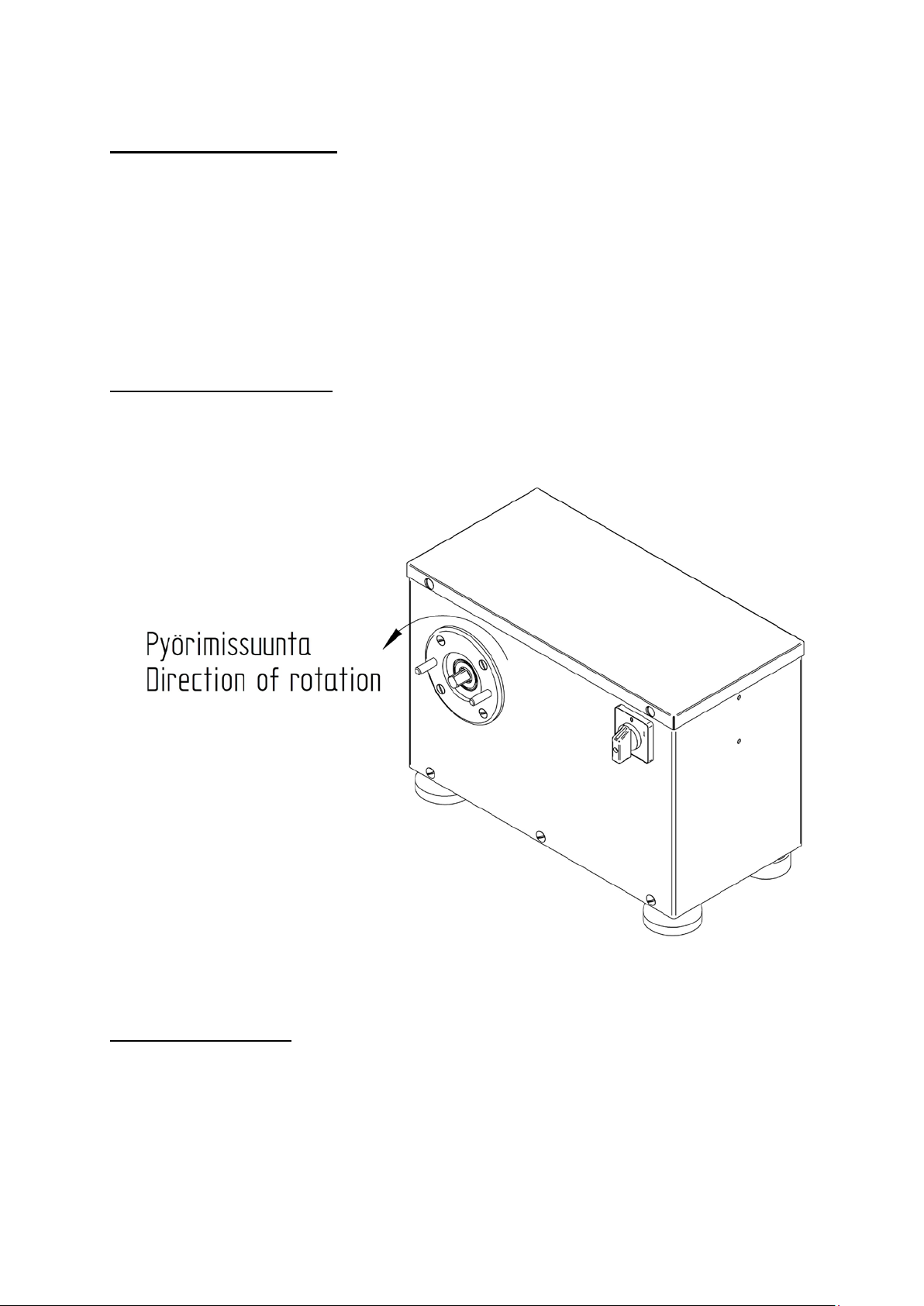

2. CHECK the direction of rotation of feed screw (counter-clockwise).

3. CHECK that the meat tray is firmly in place.

4. CHECK that the blade and hole plate to be mounted in the machine are used in pairs.

5. CHECK that the blade and hole plate are correctly mounted in the grinder housing.

6. CHECK that the edge of the hole plate remains 2-3 mm outside the housing.

7. CHECK that the entry nut is not too tight, in order to prolong the lifespan of the blade

assembly.

8. ENSURE that the diameter of the holes in the last plate towards the outlet shall be less

than 8 mm.