shielding plate (about one inch larger than the actuator

in each dimension, and at least a 1/16” thick) should be

placed between the actuator and the mounting bracket.

In addition, the actuator should not be mounted directly

above the pipe. For media temperatures above 300°F,

a valve with an extended shaft mounting arrangement

should be used.

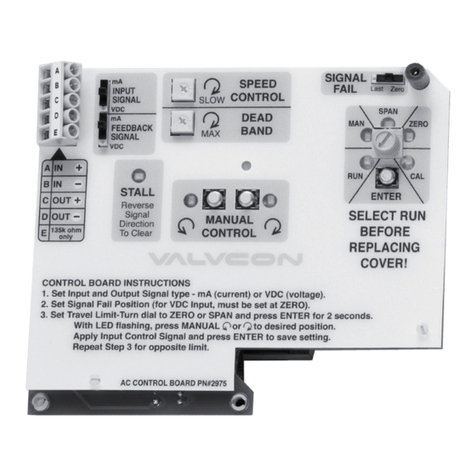

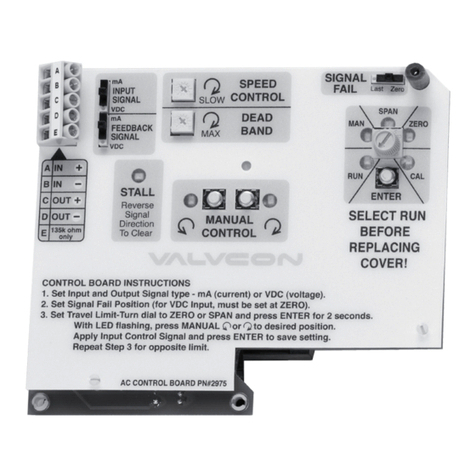

4. MOUNTING THE ACTUATOR

WARNING

DANGEROUS VOLTAGES ARE PRESENT INSIDE THE ACTUATOR

COVER UNLESS THE POWER SUPPLY TO THE ACTUATOR HAS BEEN

SHUT OFF OR DISCONNECTED. USE EXTREME CAUTION WHENEVER

WORKING ON THE ACTUATOR WITH THE COVER REMOVED.

4.1 Actuator Installation

Verify that the output torque of the actuator is appropriate

for the torque requirements of the valve. The output torque

is listed on the actuator’s base nameplate.

Actuator Drive Output - QX-Series actuators are furnished

with a female drive output. Two bolt hole patterns (ISO

5211) are provided for actuator mounting (See gure 3).

Bracket requirements - It is mandatory that the actuator be

rmly secured to a sturdy mounting bracket. A minimum of

four bolts with lock-washers should be used to secure the

actuator to the bracket. No exibility in the bracket is allowed,

and backlash, or ”play”, in the coupling should be minimized.

The actuator output shaft must be in-line (centered) with the

valve shaft to avoid side-loading the shaft.

5. MANUAL OVERRIDE

WARNING

FAILURE TO USE MANUAL OVERRIDE PROPERLY COULD RESULT

IN DAMAGE TO THE ACTUATOR GEARING. ENSURE THAT THE

OVERRIDE IS FULLY DISENGAGED AND DO NOT USE EXCESSIVE

FORCE WHEN MANUALLY POSITIONING ACTUATOR. DO NOT DRIVE

THE ACTUATOR BEYOND THE TRAVEL LIMIT SETTINGS. FAILURE TO

FOLLOW THESE INSTRUCTIONS COULD RESULT IN DAMAGE TO THE

ACTUATOR AND/OR FINAL DRIVE ELEMENT.

To use the manual override, push the override shaft down

approximately 1/4 inch to disengage the motor from the

gear train. Failure to disengage motor prior to turning

override will cause damage to the actuator. While holding

the shaft down, turn the shaft with a wrench or handle to

the desired position. The override shaft on actuators below

1000 in•lb must be rotated in the opposite direction of the

desired direction of the output shaft. In actuators 1000 in•lb

and above, the override and the output shaft turn in the

same direction.

Do not drive the actuator beyond the limit switch settings.

The manual override shaft must be returned to its fully

upward position before the motor is re-engaged. Rotate the

shaft slightly to align the spur gears until the shaft ”springs”

back to its re-engaged position. NOTE: The rotation

direction of the output may not be the same as the rotation

of the override shaft!

6. TROUBLESHOOTING

If the actuator fails to operate:

• Check that proper voltages are present at the actuator’s

terminal connections.

• Check that all connections are properly made.

• Check that the limit switches are properly set.

• Check that the actuator has enough torque output for

the application.

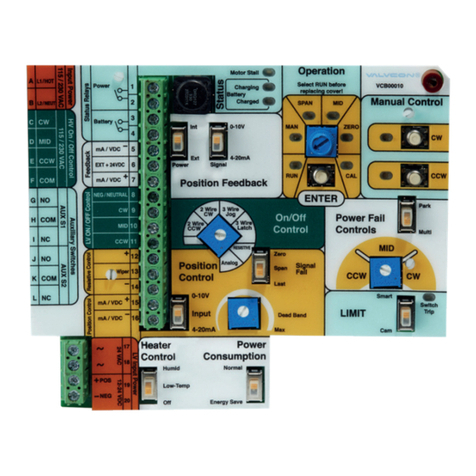

7. QXSERIES STANDARD OPTIONS

7.1 Option “H” – Tropical Heater and

Thermostat

The tropical heater and thermostat option is a selfadhesive,

resistant heater strip which is applied to primary gear-box. It

is hard-wired to the terminal block and is recommended in

high-humidity applications. The tropical heater option is also

recommended installations that experience wide temperature

swings in order to evaporate any condensation. Thermostat

is pre-set to activate at or below 90°F and deactivate at or

above 110°F. The tropical heater draws 15 watts at 12 VDC and

24VDC. This option is factory installed only.

7.2 Option Codes “I1”, “I2”, “I3”, and “I4” -

ISO 5211 Metric Output

The actuator is equipped with an ISO 5211 compliant

mounting conguration. The standard drive output for

150-600 lb-in models is a 3/4” female square. The standard

drive output for 1000-3000 lb-in models is a 1” female

square. We oer several female keyed drive output options,

consult the “How to Order” section for available sizes for a

given actuator model. This option is factory installed only.

7.3 Option “T” – Heater and Thermostat

The heater and thermostat option is a self-adhesive,

resistance heater strip which is applied to the primary

gearbox. It is hard-wired to the terminal block and is required

in installations where the ambient temperatures drop below

32°F. The heater option is also recommended in installations

that experience wide temperature swings in order to

evaporate any condensation. The thermostat is pre-set to

activate at or below 40°F and deactivate at or above 60°F. The

heater draws 15 watts at 12 VDC and 24VDC. This option is

factory installed only.

IMO 7/18

6 IMO-I3000 EN