Metso Jamesbury Series Operating and maintenance manual

Other Metso Controllers manuals

Metso

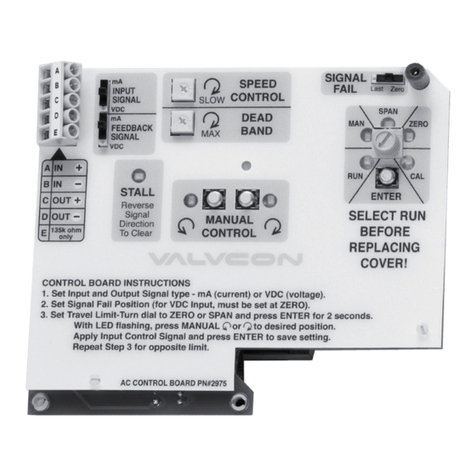

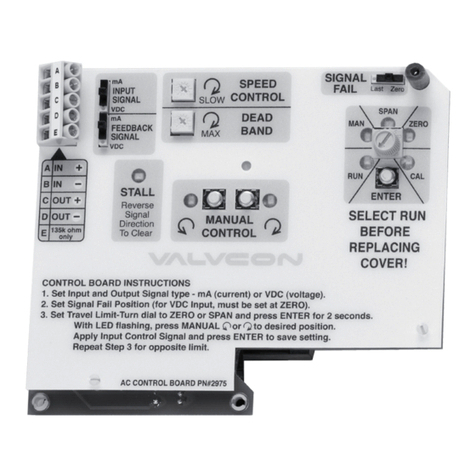

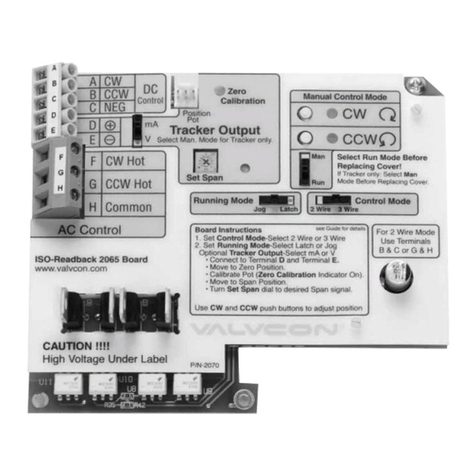

Metso VALVCON V-Series Operating and maintenance manual

Metso

Metso Valvcon LCR Series Operating and maintenance manual

Metso

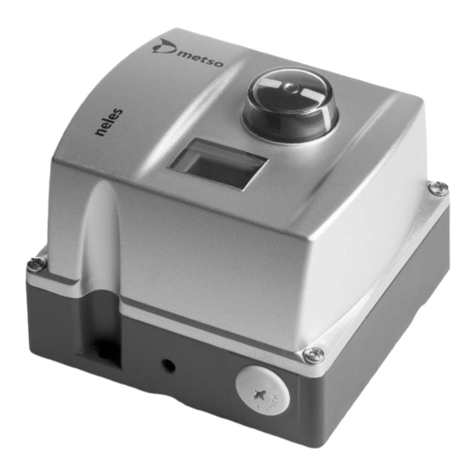

Metso neles ND9000H User manual

Metso

Metso ND9200F Operating and maintenance manual

Metso

Metso Neles ValvGuard VG9200H Operating and maintenance manual

Metso

Metso Quadra-Powr X Operating and maintenance manual

Metso

Metso Jamesbury Valv-Powr Value-Line D VPVL Series Operating and maintenance manual

Metso

Metso MOD C VALUE-LINE VALV-POWR VPVL Operating and maintenance manual

Metso

Metso Quadra-Powr II Operating and maintenance manual

Metso

Metso Nordtrack CT20 User manual

Metso

Metso ND9100H Operating and maintenance manual

Metso

Metso VD Series User manual

Metso

Metso NELES NDX Series Operating and maintenance manual

Metso

Metso neles EJ Series Operating and maintenance manual

Metso

Metso Neles ValvGuard VG9000F Operating and maintenance manual

Metso

Metso B1C series User manual

Metso

Metso VALVCON QX Series Operating and maintenance manual

Metso

Metso VALVCON V-Series Operating and maintenance manual

Metso

Metso Neles ND9100P Operating and maintenance manual

Metso

Metso Neles SwitchGuard SG9200H Operating and maintenance manual

Popular Controllers manuals by other brands

BYONICS

BYONICS PicCon v3 manual

Rain Bird

Rain Bird PRS-DIAL Installation and operation guide

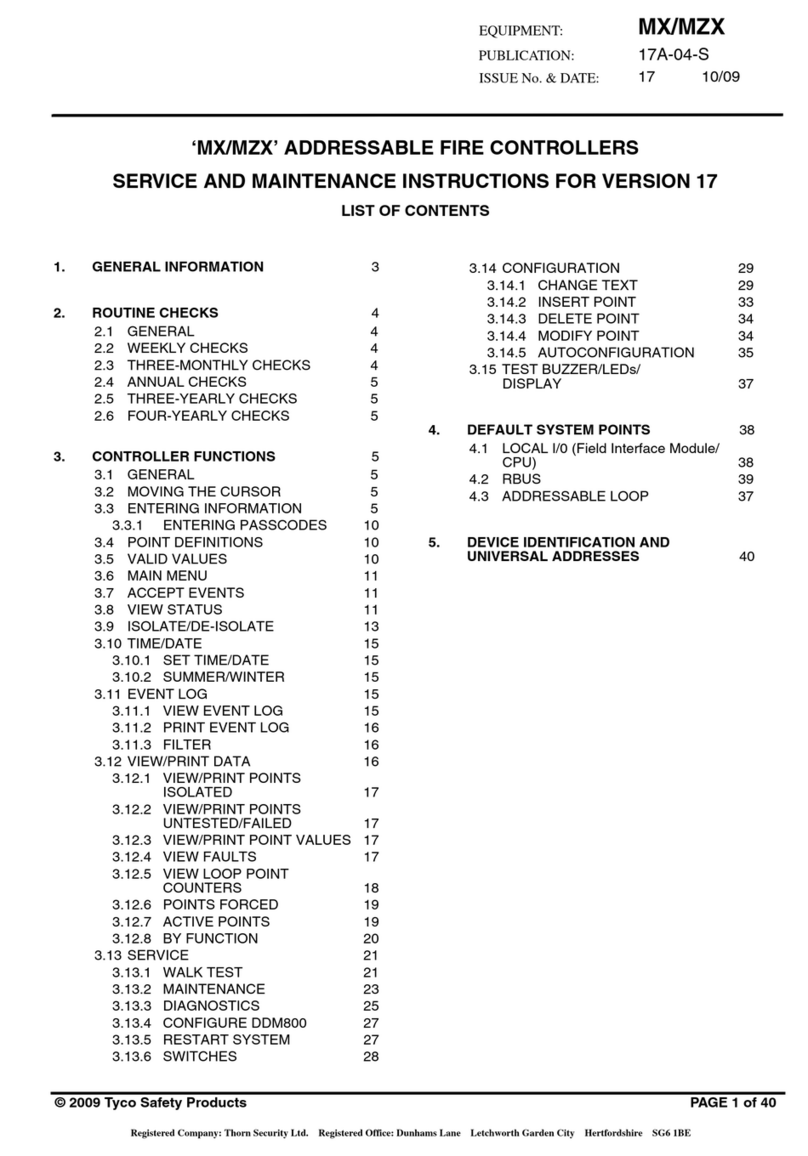

Tyco

Tyco MX Series Service and maintenance instructions

Fuji Electric

Fuji Electric MICREX-SX series user manual

Hitachi

Hitachi HIDIC EH-150 instruction manual

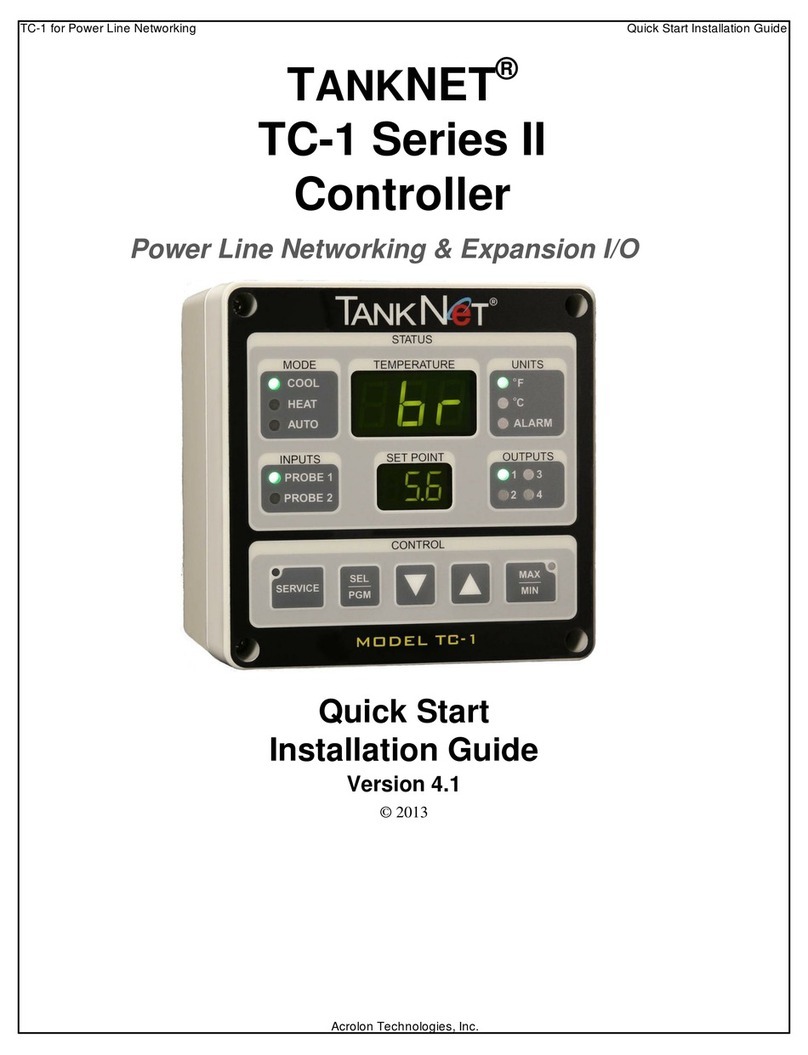

Acrolon

Acrolon TankNET TC-1 Quick start installation guide

Induction Solutions

Induction Solutions NPC-2006 user manual

Tech Controllers

Tech Controllers EU-294v1 user manual

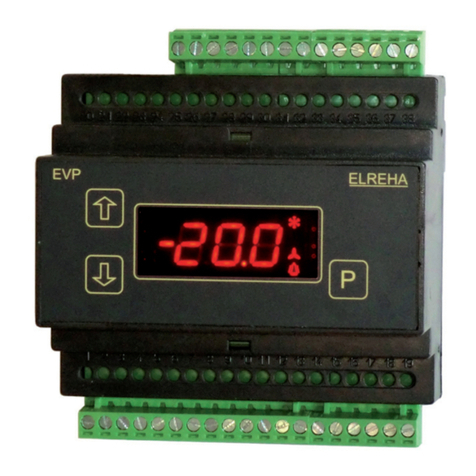

ELREHA

ELREHA EVP 3150-1 Technical manual

Mitsubishi

Mitsubishi FX-32E-TB/UL Hardware manual

Resol

Resol DeltaSol BX+ V2 Commissioning manual

Busch-Jaeger

Busch-Jaeger Busch-free@home 6213/1.1-WL product manual

ABB

ABB 6128/10 Series operating instructions

Fujitsu

Fujitsu UTY-TERX installation manual

Manson Engineering Industrial

Manson Engineering Industrial PVC-7820 user manual

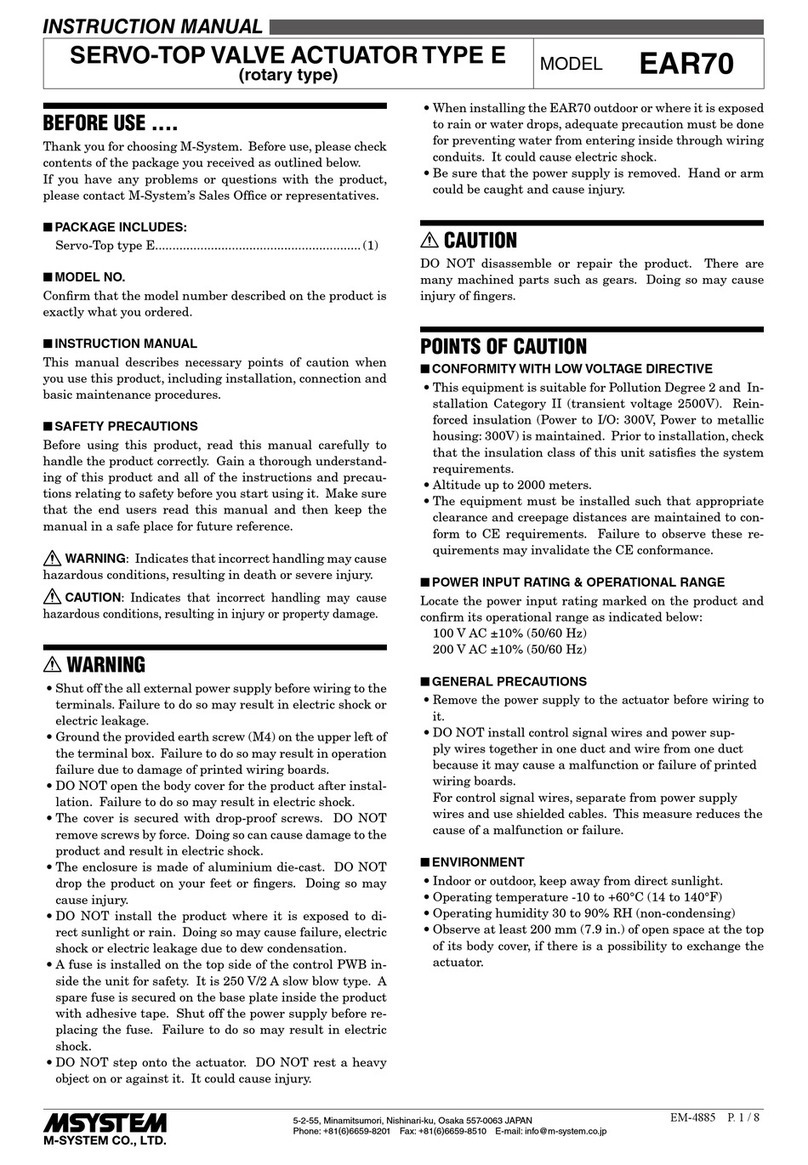

M-system

M-system EAR70 instruction manual

Murphy

Murphy EMS447 Specifications

CIMCON Lighting

CIMCON Lighting iSLC3100-7P-C-E Installation and commissioning instruction manual