7 ND91P 70 en 5

2.4 Technical specifications

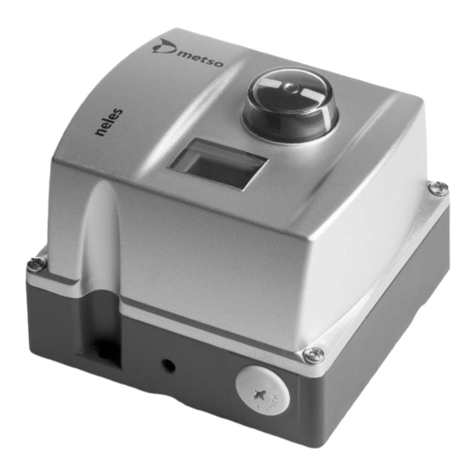

ND9100P INTELLIGENT VALVE CONTROLLER

General

Bus powered, no external power supply required.

Suitable for rotary and sliding-stem valves.

Actuator connections in accordance with VDI/VDE 3845

and IEC 60534-6 standards.

Flush mounting on NelesCV™ control valves.

Action: Double or single acting

Travel range: Linear; 10–120 mm with standard IEC parts.

Larger strokes possible with suitable kits

Rotary: 45–95°.

Measurement range 110° with freely

rotating feedback shaft.

Environmental influence

Standard temperature range:

-40° – +85 °C / -40° – +185 °F

Influence of temperature on valve position:

< 0.5 % / 10 °K

Influence of vibration on valve position:

< 1 % under 2g 5–150 Hz,

1g 150–300 Hz, 0.5g 300–2000 Hz

Enclosure

Material: Anodised aluminium alloy and

polymer composite

Protection class: IP66, NEMA 4X

Pneumatic ports: G 1/4

Electrical connection: max. 2.5 mm2

Cable gland thread: M20 x 1.5

Weight: 1.8 kg / 4.0 lbs

Mechanical and digital position indicator visible

through the main cover

Special corrosion resistant finish available

Pneumatics

Supply pressure: 1.4–8 bar / 20–115 psi

Effect of supply pressure on valve position:

<0.1 % at 10 % difference in inlet pressure

Air quality: According to ISO 8573-1:2001

Solid particles: Class 5

(3–5 µm filtration is recommended)

Humidity: Class 1

(dew point 10 °C/50 °F below minimum

temperature is recommended)

Oil class: 3 (or <1 ppm))

Capacity with 4 bar / 60 psi supply:

5.5 Nm3/h / 3.3 scfm (spool valve 2)

12 Nm3/h / 7.1 scfm (spool valve 3)

38 Nm3/h / 22.4 scfm (spool valve 6)

Consumption with 4 bar / 60 psi supply

in steady state position:

< 0.6 Nm3/h / 0.35 scfm (spool valves 2 & 3

< 1.0 Nm3/h / 0.6 scfm (spool valve 6)

Electronics

Power supply: taken from bus

Bus voltage: 9 to 32 V DC, reverse polarity protection

Max basic current:17.2 mA

Fault current (FDE):3.9 mA

EEx ia IIC T6: Ui ≤24 V

Ii ≤380 mA

Pi ≤5.32 W

Ci < 5 nF

Li < 10 µH

EEx nL IIC: Ui ≤32 V

Ii ≤380 mA

Pi ≤5.32 W

Ci < 5 nF

Li < 10 µH

(ATEX approval is valid under these conditions)

Performance with moderate constant-load,

actuators EC05-EC10

Values at 20 °C / 68 °F and without any additional instru-

ments, such as boosters or quick exhaust valves etc.

Dead band acc. to IEC 61514:

≤0.1 %

Hysteresis acc. to IEC 61514:

<0.5 %

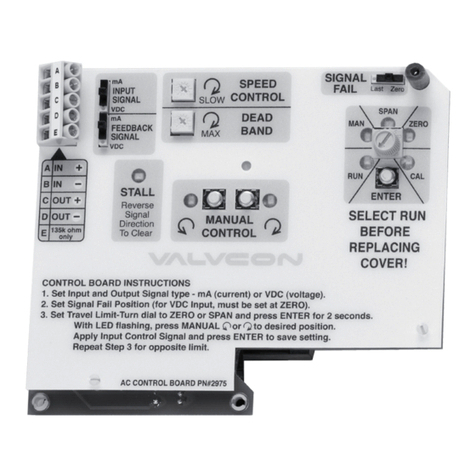

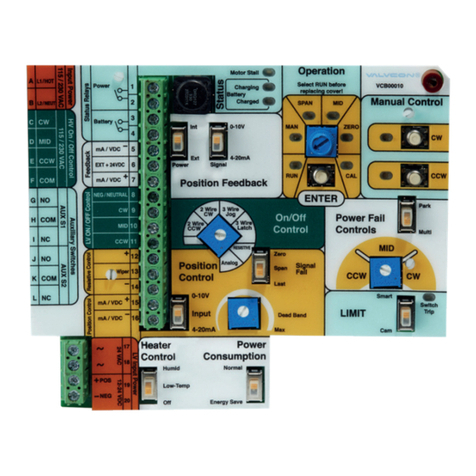

Local user interface functions

❑Local control of the valve

❑Monitoring of valve position, input signal, temper-

ature, supply and actuator pressure difference

❑Guided start-up function

❑LUI may be locked remotely to prevent unauthor-

ised access

❑Calibration: Automatic / Manual

❑1-point calibration

❑Limit switch state monitoring

❑Control configuration: aggressive, fast, optimum,

stable, maximum stability

❑Mode selection: Automatic/Manual

❑Rotation: valve rotation clockwise or counter-

clockwise to close

❑Dead angle

❑Low cut-off, cut-off safety range (default 2 %)

❑Positioner fail action, open/close

❑Actuator type, double/single acting

❑Valve type, rotary/linear IEC/nelesCV Globe/FLI

❑Language selection: English, German and French

Approvals

Intrinsically safe and non incendive

ATEX EC-Directive 94/9/EC;

EN 50014

EN 50020: 2 G EEx ia IIC T4...T6

EN 50284: 1 G EEx ia IIC T4...T6

EN50021: 3 G EEx nA II T4...T6

IEC 60079-27: EEx nL IIC

EN 50281-1-1: D T90 °C

CSA CAN/CSA-C22.2-0,-142, -157;

CAN/CSA-E60079-0,-11, -15

IS Class I, Div. 1, Groups A, B, C, D T4...T6

IS Class I, Zone 0, Ex ia IIC T4...T6

NI Class I, Div. 2, Groups A, B, C, D T4...T6

FM FM Class 3600, 3610, 3611, 3810:

IS Class I, Div. 1, Groups A, B, C, D T4...T6

IS Class I, Zone 0, AEx ia IIC T4...T6

NI Class I, Div. 2, Groups A, B, C, D T4...T6

NI Class I, Zone 2, Ex nA II T4...T6