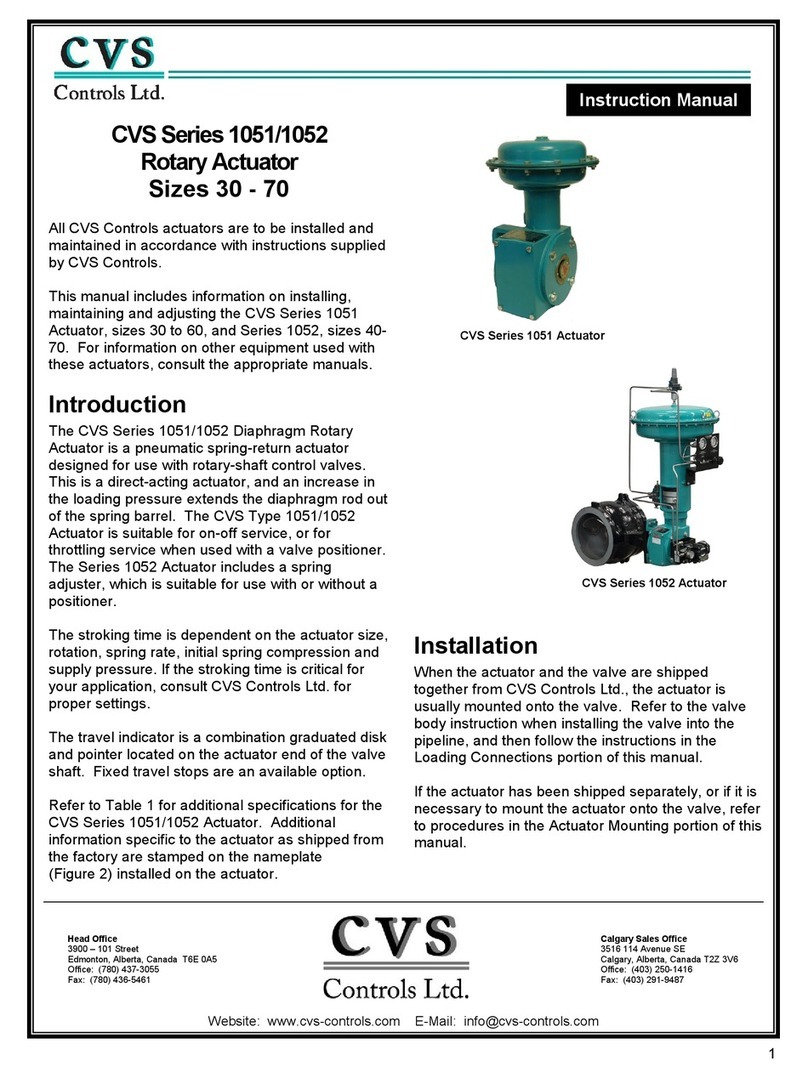

3 MOUNTING THE ACTUATOR

First verify that the output torque of the actuator is appro-

priate for the torque requirements of the valve and that

the actuator duty cycle is appropriate for the intended

application.

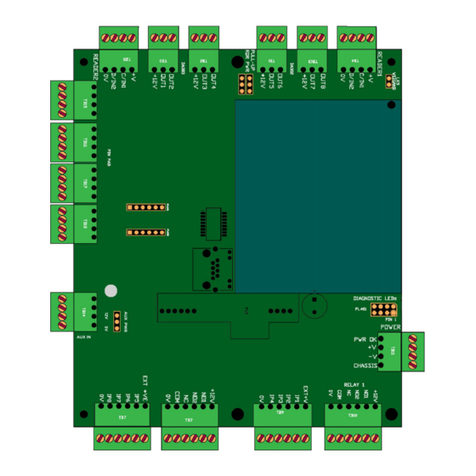

3.1 Actuator Drive Output Requirements:

Valvcon's LCR-Series actuators have a square output drive.

ISO 5211 bolt circle configurations are provided (see

Figures 2A and 2B).

3.2 Bracket Requirements:

It is mandatory that the actuator be firmly secured to a

sturdy mounting bracket. A minimum of four bolts with

lockwashers must be used to secure the actuator to the

bracket. There can be no flexibility in the bracket, and

backlash ("play") in the coupling should be minimized. In

addition, the actuator output shaft must be in line (cen-

tered) with the valve shaft. This avoids side-loading the

shafts (crossed-slot couplings are more tolerant of mis-

alignment).

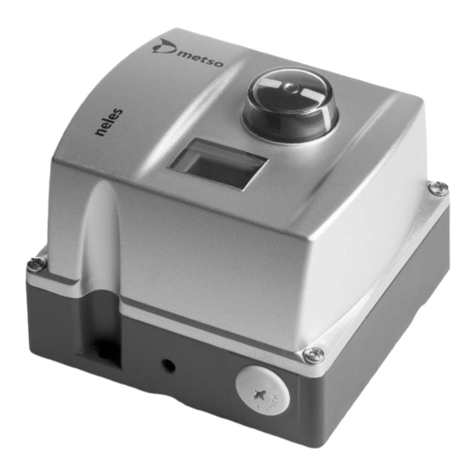

4 MANUAL OVERRIDE

4.1 Male output:

To operate the actuator manually, push the override shaft

down approximately 1/4", and use a wrench on the flats of

the shaft to rotate the actuator. As noted in Figure 2A, the

coupling must be designed to accommodate this shaft

movement. The override shaft can also be used to provide

visual identification of the valve's position.

4.2 Female output:

To operate the actuator manually, push the override shaft

down approximately 1/4", and use a wrench on the flats of

the shaft to rotate the actuator.The override shaft can also

be used to provide visual identification of the valve's posi-

tion.

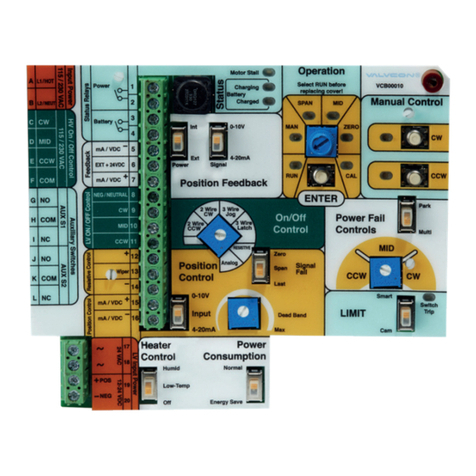

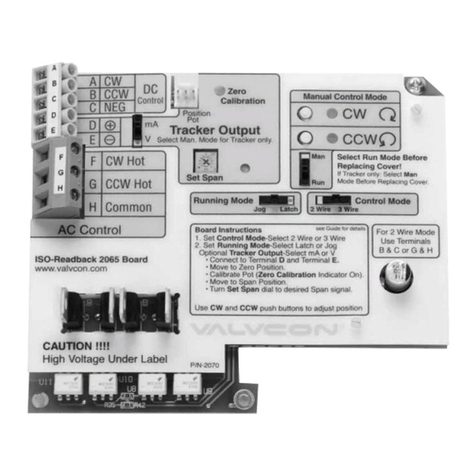

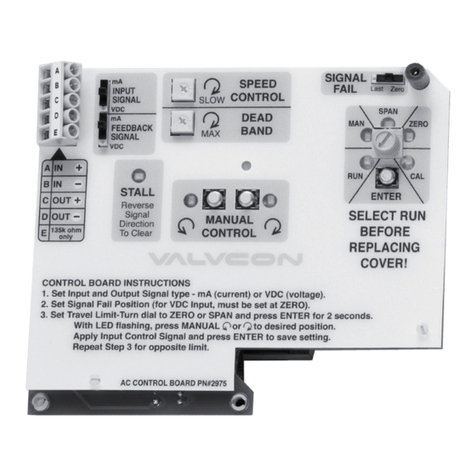

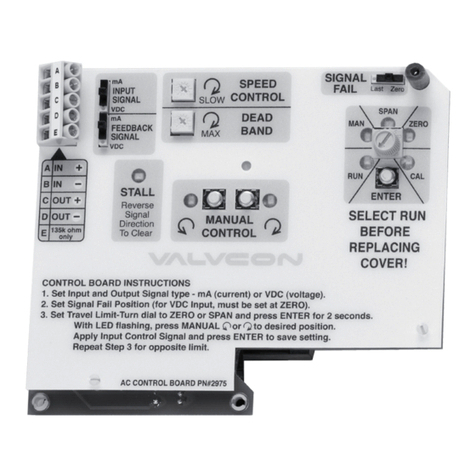

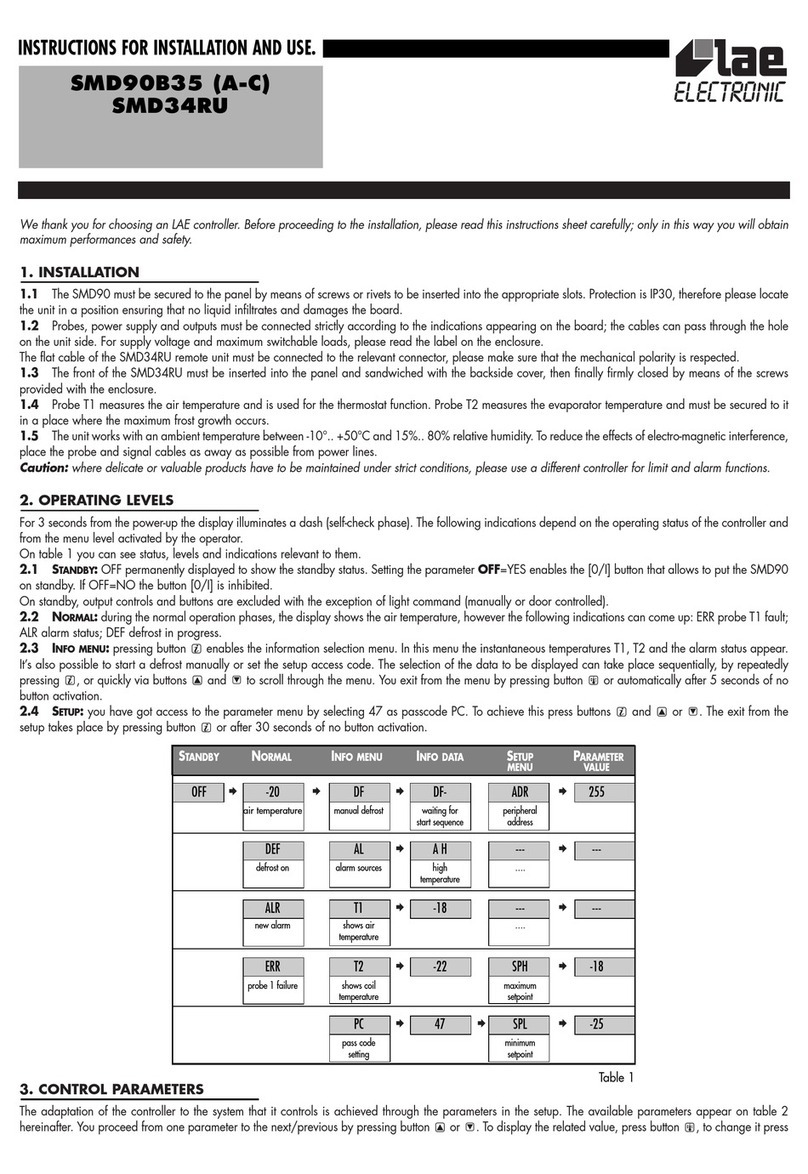

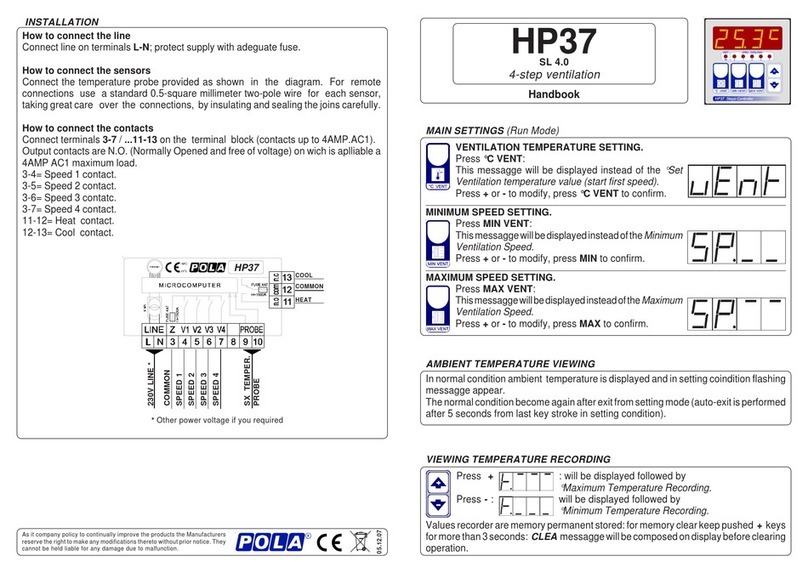

5 WIRING

Note: Be sure to follow local wiring codes.

The identification label on each actuator specifies the volt-

age and current requirements for the actuator. Figure 3

shows the standard power and control wiring connections

for AC and DC actuators. To operate the LCR-Series actua-

tor, the user supplies power to the actuator's motor

through two limit switches. The limit switches control the

actuator's mechanical travel limits and are factory set at 90

degrees.

5.1 AC

To drive the actuator counterclockwise (CCW), apply

power to terminals 1 and 3. To drive the actuator clock-

wise (CW), apply power to terminals 1 and 4. The actuator

can be driven fully open (CCW) or closed (CW) by main-

taining power to the motor until the actuator trips the

internal limit switches. Power can also be disconnected at

any point during the travel to position the actuator. (see

Figure 3A)

5.2 DC

DC voltage actuators require a reversing of the power

polarity. To drive the actuator CW, apply power so that ter-

minal 1 is negative and terminal 4 is positive. To drive the

actuator CCW, apply power so that terminal 1 is positive

and terminal 3 is negative. (see Figure 3B)

NOTE: LCR series actuators have a 25% duty cycle,

which means that for every operating cycle that the

actuator is ON (to open or close the valve), the actuator

must be OFF for a time equal to three operating cycles.

For example, if the operating cycle time is 5 seconds,

for every operating cycle that the actuator is ON, it

must be OFF for 15 seconds. Exceeding the actuator's

duty cycle may cause the thermal overload switch to

temporarily shut off power to the motor.

6IMO-I1262