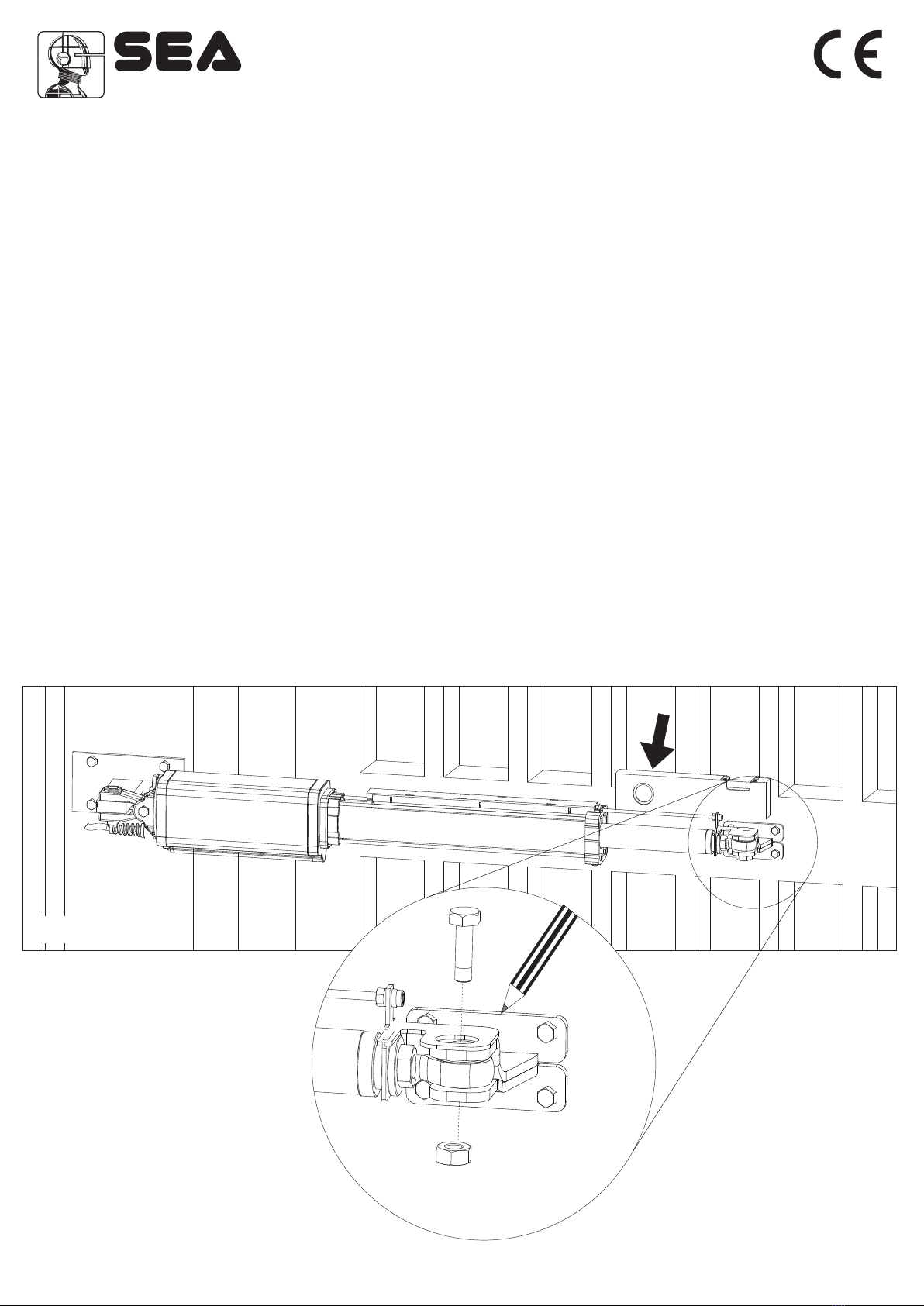

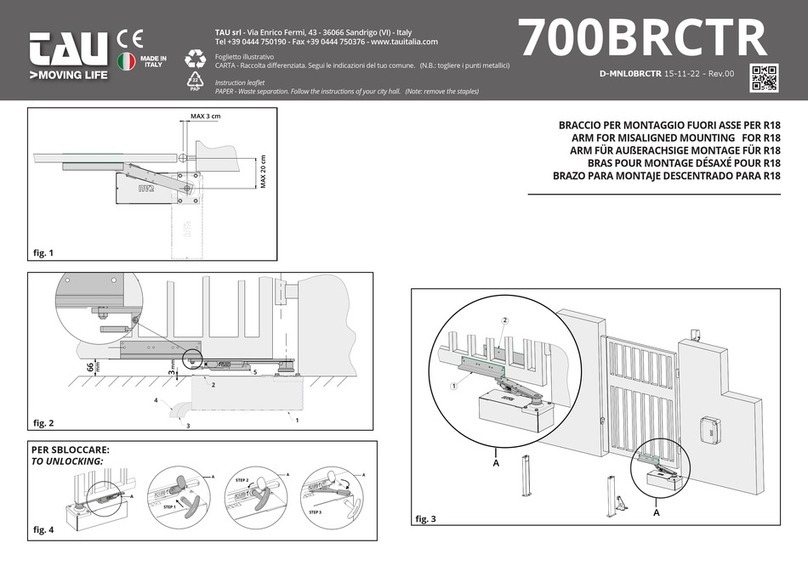

POSIZIONAMENTO DELL’ATTACCO ANTERIORE

Una volta fissato l’operatore sull’attacco posteriore portare l’anta del cancello in posizione di chiusura ed eseguire le seguenti operazioni:

1)Tirare fuori completamente lo Stelo cromato, poi riportarlo indietro di minimo 1 cm

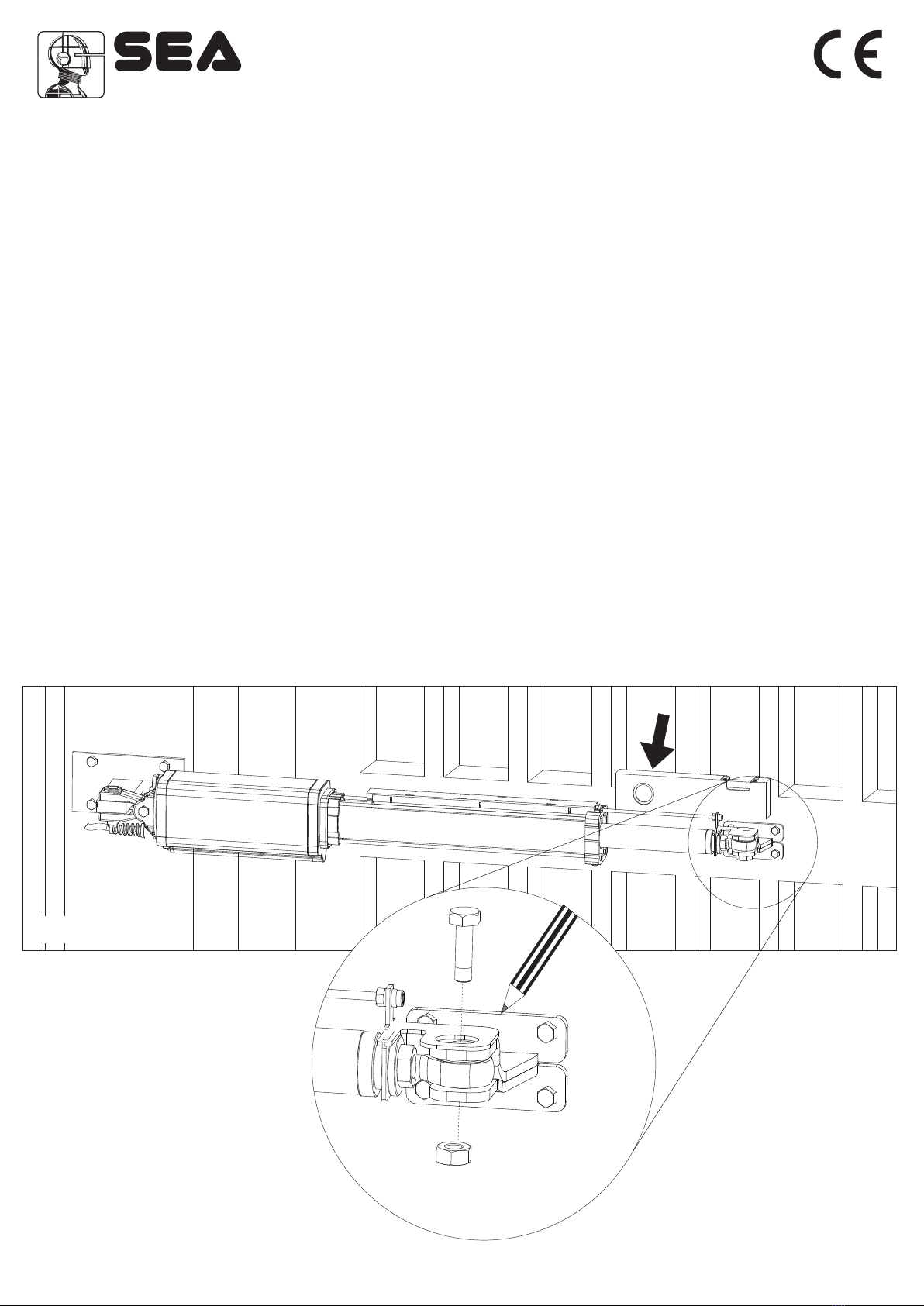

2) Fissare lo stelo sul attacco anteriore (Fig. 4).

3) Posizionare l’operatore in modo che risulti perfettamente orizzontale e quindi segnare la posizione dell’attacco anteriore (Fig.3).

Attenzione: evitare di saldare l’attacco anteriore con lo stelo dell’operatore già fissato; i residui (schizzi) di saldatura potrebbero

compromettere la cromatura dello stelo.

POSITIONING OF THE FRONT FIXATION

Once the operator has been mounted on the back fixation close the leaf and do as follows:

1) Pull out completely the chromium plated rod, afterwards bring it back about 1 cm

2) Fix the rod on the front fixation (Fig. 4).

3) Position the operator perfectly horizontal and mark the position of the front fixation (Fig.3).

Attention: Avoid the welding of the front fixation to the rod of the operator already fixed as the welding residual (squirt) could ruin the chromium -

plating of the rod.

POSITIONNEMENT ATTAQUE ANTERIEUR

Après avoir fixé l’opérateur sur l’attaque postérieur fermer le vantail et exécuter le suivantes opérations:

1)Sortir complètement la tige chromée, après la rentrer d’au moins 1 cm.

2) Fixer la tige sur l’attaque antérieur (Fig. 4).

3) Positionner l’opérateur de façon parfaitement horizontal donc marquer la position de l’attaque antérieur (Fig. 3).

Attention: éviter de souder l’attaque antérieur avec la tige de l’opérateur déjà fixée: Les déchets de soudure pourraient compromettre le

chromage de la tige.

POSICIONAMIENTO DEL ENGANCHE ANTERIOR

Una vez fijado el operador en el enganche posterior llevar el anta de la cancela en posicion de cierre y efectuar las siguientes operaciones:

1) Jalar hacia fuera completamente la varilla cromada,de minimo 1 cm.

2) Fijar la varilla en el enganche anterior (Fig. 4).

3) Posicionar el operador en modo que resulte prefectamnete horizontal y por tanto señalar la posicion del enganche anterior (Fig. 3).

Atencion: evitar de soldar el enganche anterior con la varilla del operador ya fijado; los residuos (salpicaduras) de soldadura podria

comprometer la cromadura de la carrera.

3

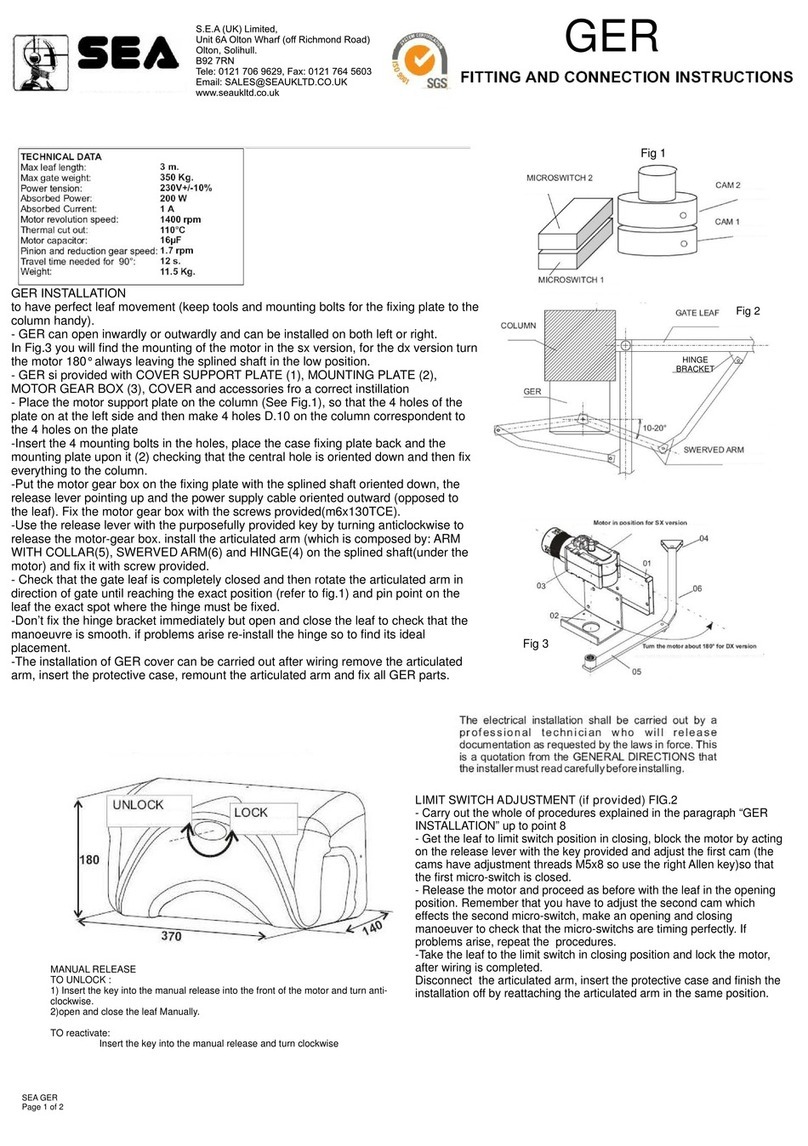

Fig. 3

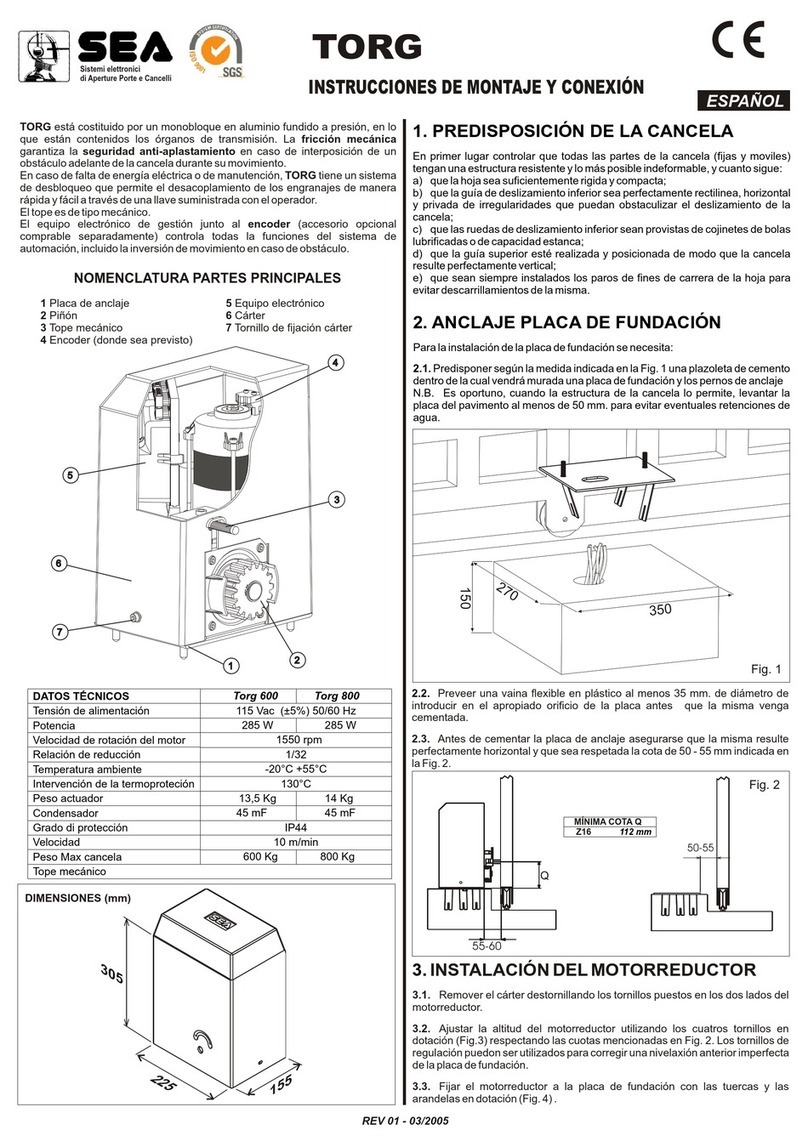

Fig. 4

Sistemi Elettronici

di Apertura Porte e Cancelli

®