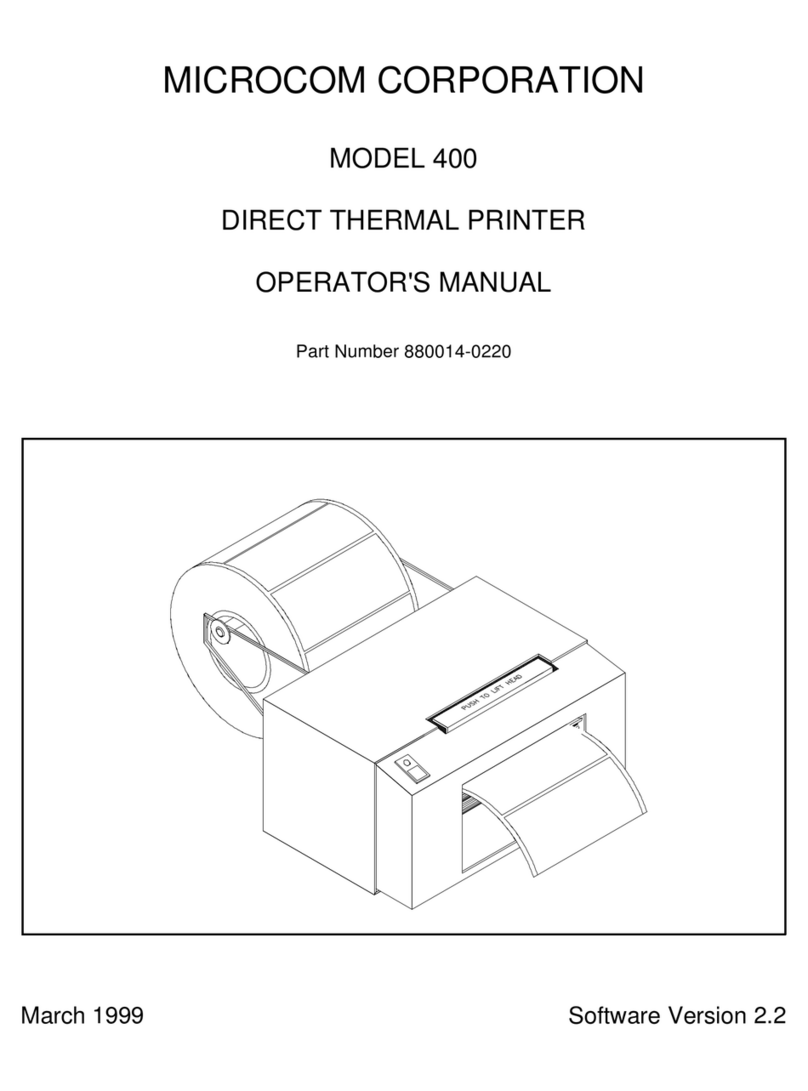

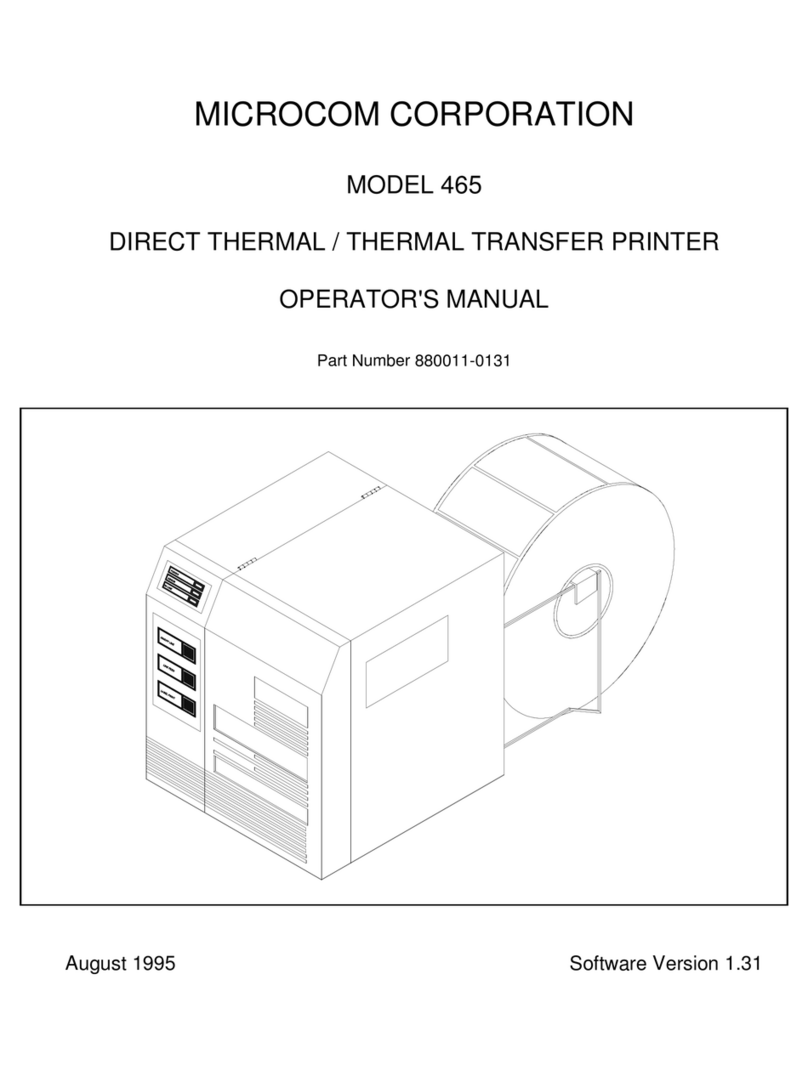

466 Operators Manual

Table of Contents

List of Tables ..............................................................v

List of Figures ..............................................................v

Introduction ................................................................1

CHAPTER 1: FEATURES AND SPECIFICATIONS .................................3

1.1 SPECIAL FEATURES ............................................3

1.2 BAR CODES ...................................................3

1.3 FONTS .......................................................4

1.4 PRINTING .....................................................4

1.5 INTERFACE COMMUNICATIONS ...................................4

1.6 PHYSICAL .....................................................4

1.7 ENVIRONMENT ................................................4

1.8 ELECTRICAL ...................................................5

1.9 OPTIONS ......................................................5

1.10 PRINTER VARIATIONS ...........................................5

1.11 APPROVALS ...................................................5

CHAPTER 2: BASIC OPERATION ..............................................7

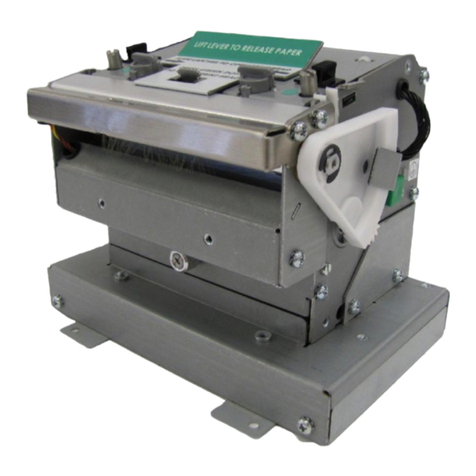

2.1 UNPACKING THE 466 PRINTER ...................................7

2.2 INITIAL POWER UP .............................................7

2.3 FRONT PANEL SWITCHES AND STATUS LIGHTS .....................7

2.3.1 NORMAL MODE ..........................................7

2.3.2 STATUS LABEL MODE .....................................7

2.3.3 PAPER-OUT MODE .......................................8

2.4 THE STATUS LIGHTS AND SOUNDS ...............................9

2.5 LOADING PAPER ...............................................9

2.5.1 NORMAL AND TAG/TEAR MODES ..........................10

2.5.2 PEEL-AND-DISPENSE MODE ..............................10

2.6 PRINT HEAD SUPPORT ADJUSTMENT ............................10

2.7 CLEANING INSTRUCTIONS ......................................11

CHAPTER 3: COMMUNICATIONS .............................................13

3.1 CABLE PINOUT ...............................................13

3.2 PRINTER CABLES .............................................14

CHAPTER 4: DESIGNING LABELS USING LDS ..................................15

4.1 CONTROL CHARACTERS .......................................15

4.2 GETTING STARTED ............................................15

4.2.1 PC CONNECTION (SERIAL) ................................15

4.2.2 PC CONNECTION (PARALLEL) .............................16

4.2.3 LEARNING LDS .........................................16

4.3 FORMATTING LABELS: AN OVERVIEW ............................17

4.4 LABEL HEADER ...............................................19

4.4.1 A SAMPLE SESSION (HEADER) ............................23

4.5 LABEL FIELDS ................................................24

4.5.1 BIT MAPPED TEXT, BAR CODE, AND GRAPHIC FIELDS .........24

4.5.2 LINES .................................................29