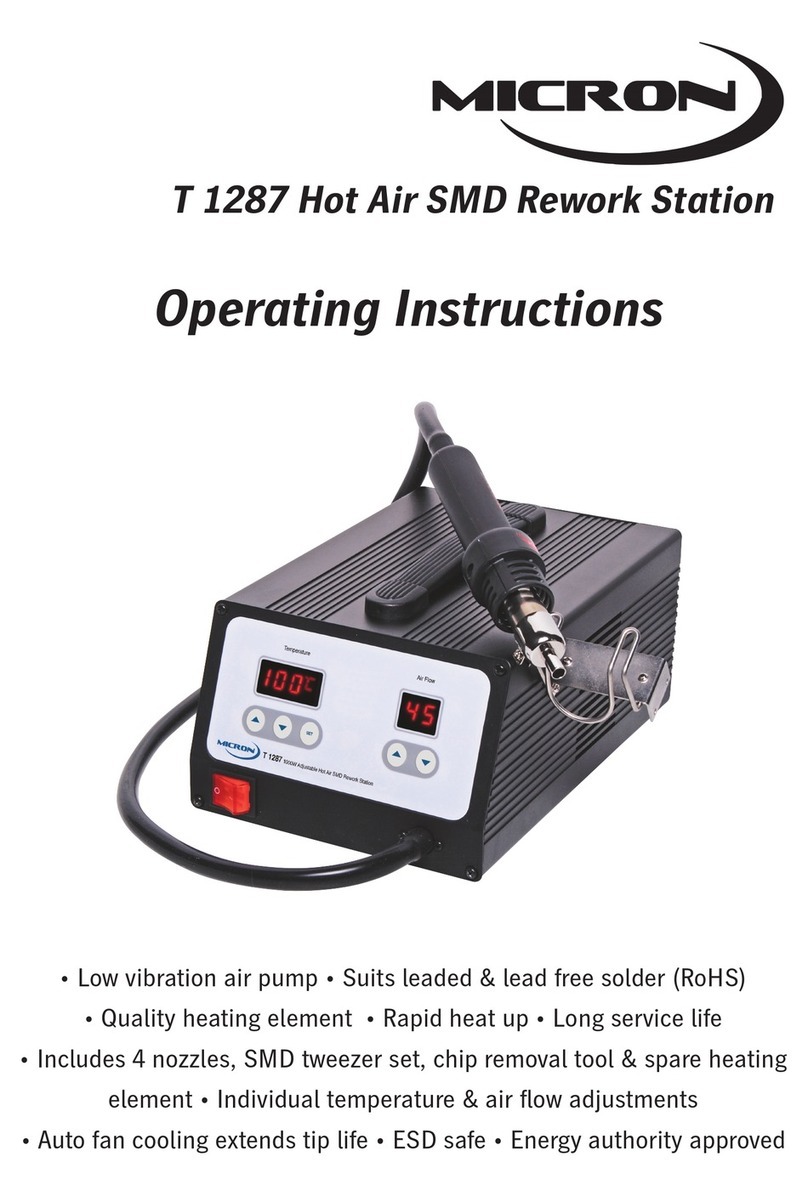

Micron® 320W Hot Air SMD Rework Station

Altronic Distributors warrants this product for one year from date of purchase from Altronics or its resellers

to the consumer. If this item is part of an installation or another product, please contact the installer or

supplier for your warranty.

During the warranty period, we undertake to repair or replace your product at no charge if found to be

defective due to a manufacturing fault. The warranty excludes damage by misuse or incorrect installation

(i.e. failure to install and operate device according to specications in the supplied instruction manual),

neglect, shipping accident, or no fault found, nor by use in a way or manner not intended by the supplier.

For repair or service please contact your PLACE OF PURCHASE.

If this item was purchased directly from Altronics please make a warranty claim by:

1. FOR MAIL ORDER CUSTOMERS (includes school and trade orders),

a) Calling your nearest store location and quoting your tax invoice number.

b) Upon contacting Altronics, we will issue an R.A. (Return Authorisation). As Altronics have a number of

service agents throughout Australia, a copy of the R.A. will be emailed, faxed or mailed to you with full

instructions of how and where to send the goods. The freight for shipping goods back to

Altronics for all repairs is at the customers expense.

c) A copy of the R.A. form, (or at the very minimum, the R.A. number) must accompany the

goods to effect the repair.

d) Altronics will pay the return freight to the customer where the warranty claim has been accepted.

e) Please quote the R.A. number in any correspondence to us.

2. FOR OVER THE COUNTER PURCHASES to make a warranty claim, please return the goods to us in

any of our stores, with a copy of your proof of purchase (tax invoice).

a) Upon leaving the goods at one of our stores, an R.A. number will be issued to you.

b) Once repaired, you will be contacted, advising that the goods are ready to be collected from the store.

It is at Altronics discretion as to whether the goods will be repaired or replaced (whilst under warranty); and

as to whether identical goods will be used to replace the item due to changes of models / products.

Note: Under no circumstances should you attempt to repair the device yourself or via a non-authorised

Altronics service centre, as this will invalidate the warranty!

Our goods come with guarantees that cannot be excluded under the Australian Consumer Law. You are

entitled to a replacement or refund for a major failure and for compensation for any other reasonably

foreseeable loss or damage. You are also entitled to have the goods repaired or replaced if the goods fail

to be of acceptable quality and the failure does not amount to a major failure.

Distributed by Altronic Distributors Pty. Ltd.

Phone: (08) 9428 2199

altronics.com.au

Revision 16/10/2020