MICRON

12. When the power is switched off, the unit will briefly continue to blow cooling air through the pipe. Do not

disconnect the plug during this cooling process.

13. Do not leave the machine unattended while switched on and operating. Turn off the machine and unplug

the power cord when you are leaving and put the hot air nozzle in the holder on one side of the machine.

Always replace the hand tool in its holder when not being used. The nozzle and the heating element

remain hot after being switched off.

14. Do not use if damaged: If the pump stops working or the rework station becomes faulty, immediately

discontinue using the unit. Only authorized technicians are able to safely repair the unit or replace

parts. Do not disassemble the pump.

TO PREVENT ELECTRICAL SHOCK, TAKE THESE PRECAUTIONS:

1. Death or serious injury may result from electric shock. It is therefore essential to isolate the equipment

from the mains before commencing maintenance or repairs. Remember to unplug in the power cord.

2. Always connect the unit to a grounded power socket.

3. Do not pour water/liquids or subject the heating surface to physical shock. This may damage the heater.

Avoid contact with moisture.

4. The station must be switched off and the power cord must be unplugged before replacing the fuse in the

AC socket at the rear side of the machine.

5. Turn the power switch off and remove the AC power cord by pulling the plug (not the cable) when the

unit will remain unused for a long period of time.

PRODUCT FEATURES:

?Specially-designed intelligent chip microcomputer control system

?Easy to read digital LED displays with simple to use operating buttons to control temperature and air flow.

?The temperature can be locked by a “password” code that is convenient for production line management.

?Quick heating high-power heating element, with a maximum of 600W.

?Ideally suited to desoldering ICs such as: QFP, SOP, PLCC or SOJ chips etc.

?The built in static-free circuit design is safe for the sensitive circuit components elements like CMOS ICs.

?Auto shutoff handpiece cradle (Air power is shut off when handpiece is placed in cradle)

?Auto-cooling design: When the power is switched off, the cooling system begins automatically, and the

temperature will drop gradually down to 100 degrees Celsius (212°F) to protect the heating element from

burning out.

?Sensor / Pump Failed Detection - If the sensor circuit fails, the display reads ‘S-E’ and the power to the

heating nozzle is cut. If the pump circuit fails, the display reads ‘P-E’ and the power is cut to the heating

nozzle.

?Heating element auto-protecting function: When the heating element reaches a high temperature, this

function automatically protects the element, and thereby preventing the element from premature failure.

INSIDE THE BOX:

?T 1287 Workstation and air pump handle / pencil.

?Nozzles: 10mm x 10mm; 14mm x 14mm; 4mm dia; 7mm dia.

?Pliers (Tweezer) – 4 different sets, non-magnetic stainless steel.

?Heating elements.

?IC removing wire tool.

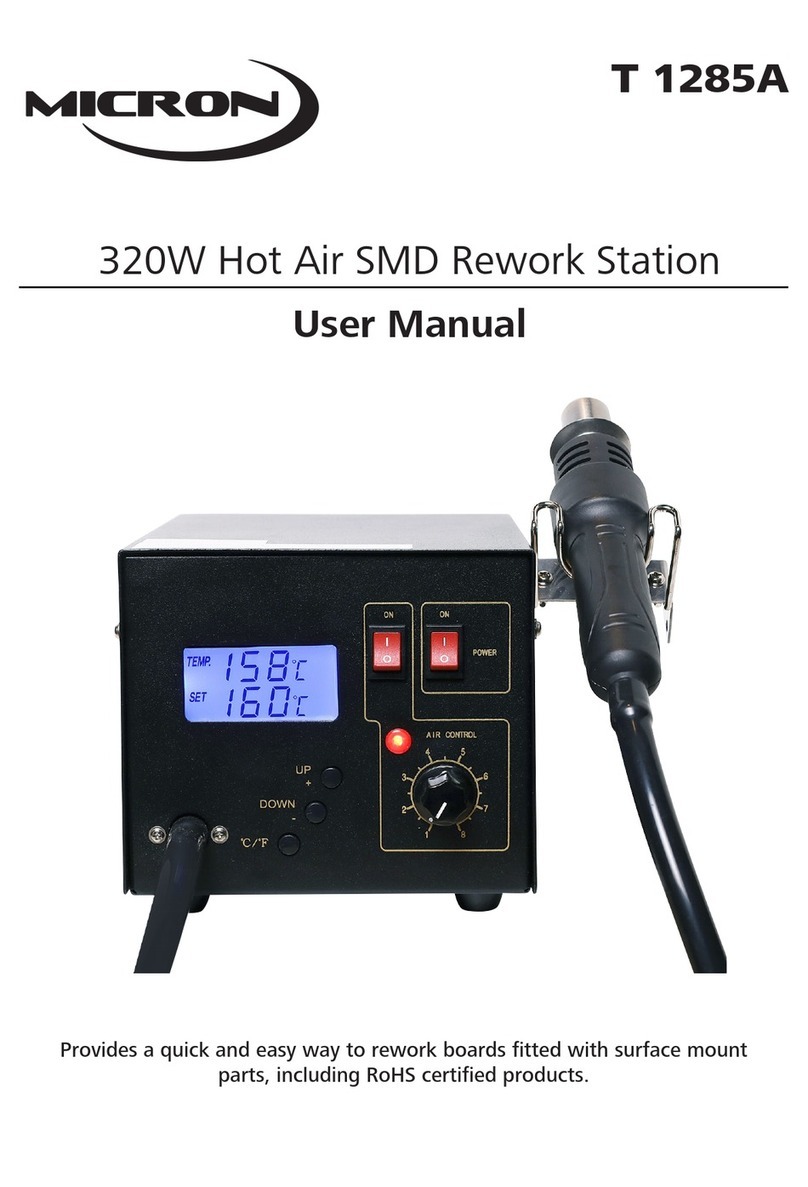

PRODUCT DESCRIPTION

The temperature-controlled LF-852DII Hot-Air SMD rework station has been built around an intelligent

microcomputer chip, which is specially designed to work with lead free SMD chips such as SOIC, CHIP, QFP,

PLCC, BGA etc. It also meets RoHS standards requirement. This appliance is equipped with a high-power

heating element that heats up quickly. High-quality sensors and consistent heat-transfer technology ensure

precise temperature regulation. The aluminum housing is strong and acts as a reliable heat sink and is

resistant to electro-magnetic interference.

3