MICRONMICRON

TIP REPLACEMENT AND CARE OF TIPS:

Caution: The soldering iron can be very hot. Be sure to turn the unit off prior to carrying out any maintenance

or trouble shooting steps listed below.

IMPORTANT: Remove and clean the tip daily. Tips can be changed or replaced simply by unscrewing the

knurled nut barrel assembly. The station must be switched off and allowed to cool before this operation as

damage may result if the system is left on without the tip inserted.

If a new tip is installed, or to maintain the current tip, remove any loose build up in the barrel assembly,

otherwise the tip may fuse to the heating element or retaining barrel. After removing the tip, blow out any

oxide dust that may have formed in the tip retaining area of the barrel. Be careful to avoid getting dust in

your eyes. Replace the tip and screw back the knurled nut barrel assembly using only firm hand pressure to

tighten. Pliers should only be used to tighten the nut to avoid burning your fingers and care should be taken

not to over-tighten as this would damage the element. The solder tips supplied are nickel/chrome plated

pure copper and if used properly will give a long life.

General Cleaning

After use, the solder waste is stored in the pipe. If you do not clean it regularly, the solder waste will block

the de-soldering gun. When under high temperature, the solder waste will oxidize (lead free solder’s melting

point is 220°C, non-lead free solder’s melting point is 180°C), swell and get stuck on the inner wall tightly.

Eventually this build-up will be nearly impossible to remove so its important to follow the general cleaning

steps listed below.

1. After each operation is finished, please pump the de-soldering gun trigger 3-5 times rapidly while idling, to

clear the solder waste inside the pipe

2. If the operation interval is about 20 minutes, while the de-soldering gun suction is idle, please use the

cleaning tool to clean the pipe.

3. When you find the de-soldering efficiency reducing, please use the cleaning tool to clean the pipe

immediately.

4. If there is a long interval of idle usage, we advise to adjust the temperature to about 200°C. When you use it

again you can adjust to the working temperature.

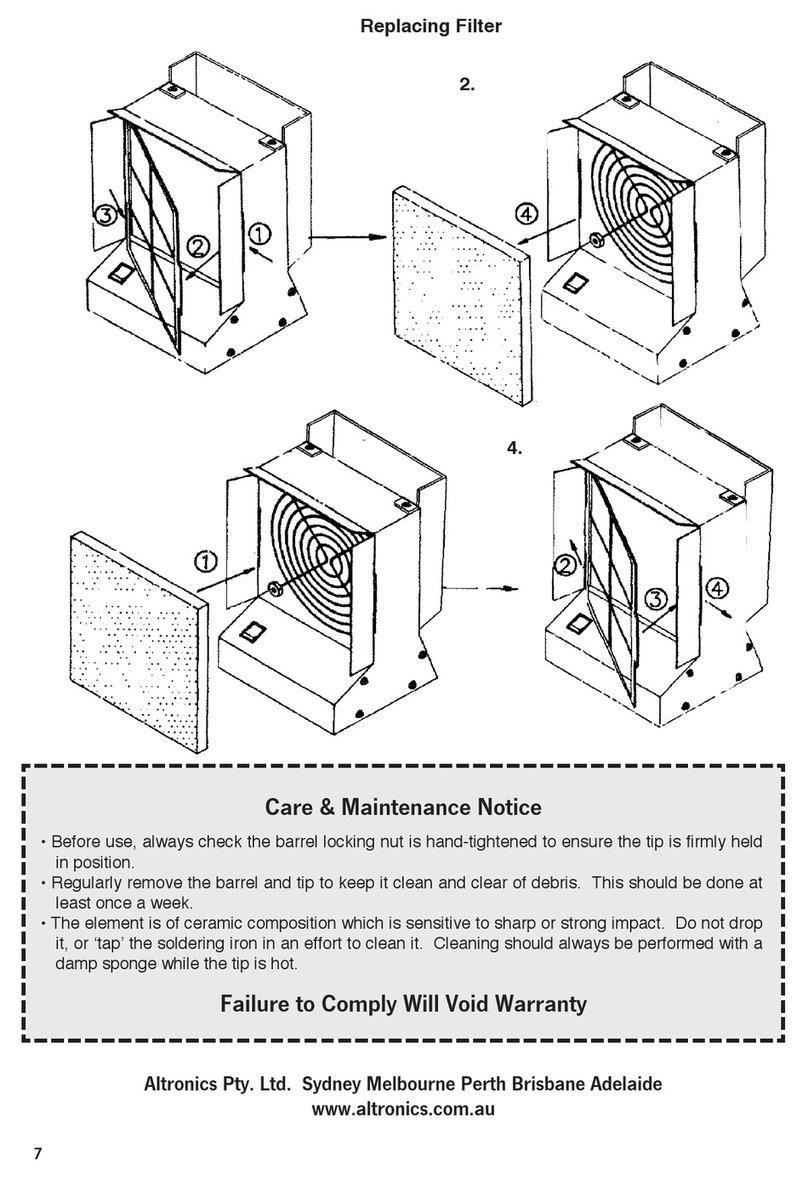

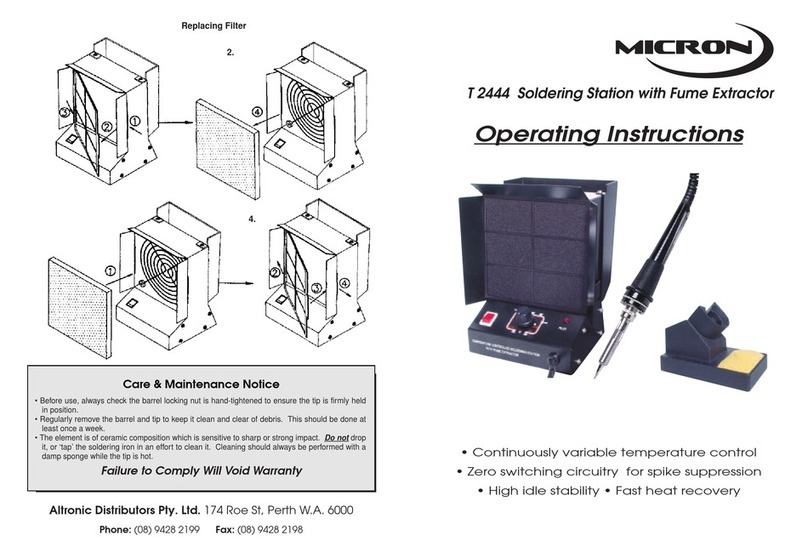

5. When the glass tube has absorbed about 1/2 solder waste, please clean it immediately. When you find the

filter is becoming clogged up, please replace the filter.

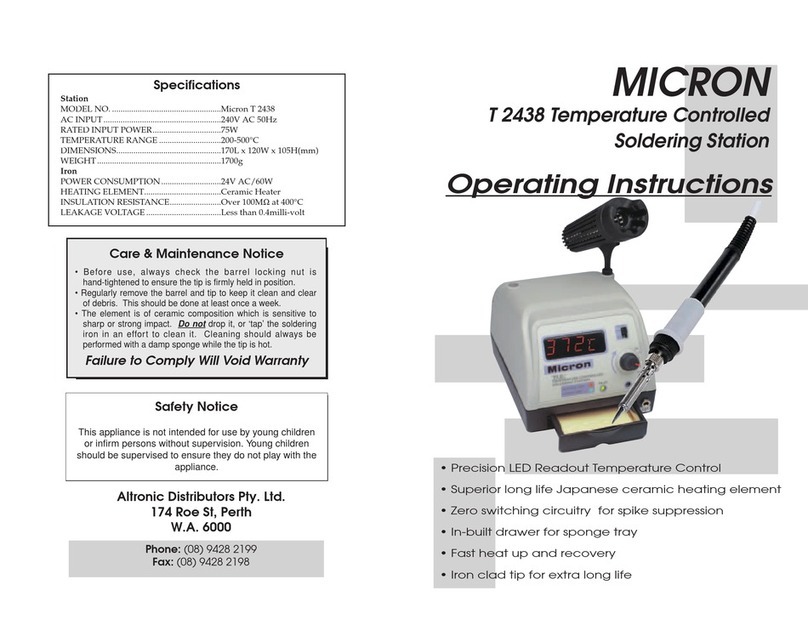

T 2052 Specifications

Input:............................................................................................................................................ 220 - 240V AC

Heater:............................................................................................................................... 24V ceramic element

Soldering nominal power: ........................................................................................................................... 60W

De-soldering nominal power: ..................................................................................................................... 90W

Temperature range: ................................................................................................................... 160°C to 480°C

Tip to ground resistance: ....................................................................................................................<0.1 Ohm

Soldering heat up time: .......................................................................................................... ≈22 sec to 400°C

De-soldering heat up time: ..................................................................................................... ≈80 sec to 400°C

Dimensions: ................................................................................................................220W x 215D x 160Hmm

Weight: .........................................................................................................................................................6kg

3

Safety Instructions

The manufacturer assumes no liability for uses other than those described in the operating instructions or

for unauthorized alterations. The operating instructions and cautions should be read carefully and kept in

an easily visible location in the vicinity of the control system. Non-observance of the cautions will result in

accidents, injury or risks to health.

1. The power cord only can be inserted in approved power sockets or adaptors.

2. High Temperature: The temperature of the tip will reach as high as around 400°C(752°F) when the power

switch is on.

Since mishandling may lead to burn and fire, be sure to comply with the following precautions:

•Do not use this system near the flammable items.

•Advise other people in the work area that the unit can reach a very high temperature and should be

considered potentially dangerous.

• Turn off the power switch while taking breaks and when finished using.

• Before replacing parts or storing the unit, turn off the power and let it cool to room temperature.

Warning: This tool must be placed on its stand when not in use.

A fire may result if the appliance is not used with care, therefore it would be advised to take note of these tips

• Do not apply heating to the same place for a long time;

• Do not use in presence of an explosive atmosphere;

• Be aware heat may be conducted to combustible materials that are out of sight;

• Never leave the appliance unattended when it is switched on.

3. Take care of your tools by following these points

• Do not use the tools for any applications other than soldering or de-soldering.

• Do not rap the iron/gun against the work bench or otherwise subject the iron to severe shocks.

• Do not file the soldering tip to remove the oxide, please wipe the tip on the cleaning sponge.

• Use only accessories or attachments which are listed in the operation manual. Use of other tools and

other accessories can lead to a danger of injury.

• Please turn off the power before connecting or disconnecting the soldering iron.

4