MVA003E User manual and device specification

Preliminary

April 2019 Page 4 of 24 1DSMVA003E_0419v9e

4 System description

This document defines the properties of Micropelt’s battery free thermostatic radiator valve MVA003E.

The unit is directly mounted onto the radiator valve bodies (standard valve connection M30x1.5), where

it controls the room temperature, based on signals of a central controller. To operate the device, the unit

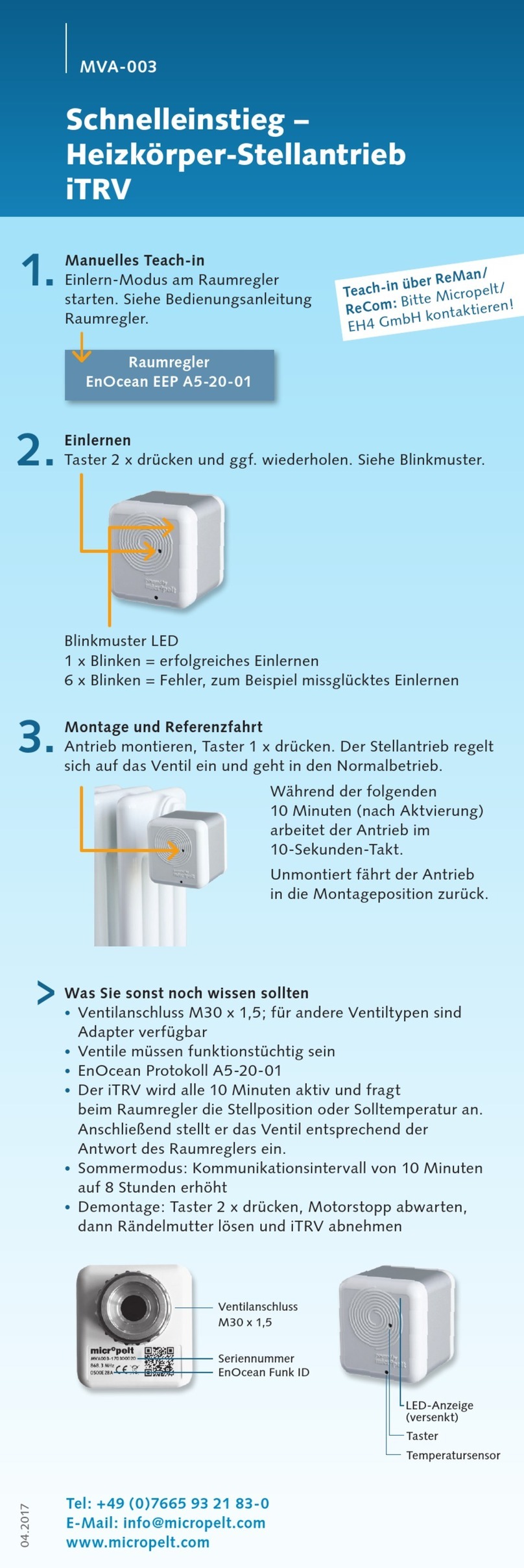

must be paired with a compatible room controller or gateway unit supporting EEP A5-20-01. The pairing

is done either via manual 4BS (Variation 3) Teach-In or trough EnOcean Remote Commissioning. Once

mounted and activated on the valve body, a calibration cycle starts to automatically adapt itself to the

individual valve and is ready for use. Adapter are available for a majority of non M30x1.5 valve bodies.

It is radio-controlled and powered by energy harvesting, so it neither requires any cabling work nor does

it consume batteries. It is designed for maintenance-free operation. The wireless design makes the unit

ideal for retrofit installation and cost-sensitive projects, where cabling cost is prohibitive.

The actuator generates its required electrical energy for operation (motor, sensors and radio

communication) by means of a built-in thermoelectric generator (TEG) and therefore operates

maintenance-free. It is powered from the temperature difference between the radiator heat and ambient

temperature (usually room temperature). An additional energy source such as a battery or external

power supply is not required. The internal energy storage is fully charged upon delivery, so that sufficient

energy is available for installation and up to approximately one year of operation. In winter and heating

season, the actuator then supplies itself independently trough the converted heat of the heating circuit.

Due to the surplus of generated energy in winter, the internal storage provides sufficient energy for 365

days per year operation including transition periods and summer.

The product is delivered in mounting position (off) with the valve plunger completely retracted. The

device does recognize when installed on a valve body by means of internal force and travel distance

measurement. Unmounted activation will always return the device back to mounting position to switch

off. The MVA003E unit does have a built-in motor error detection "ACO". The ACO bit does signal

incomplete or unsuccessfulreference runs from mounting, motor issues during normal operation as well

as motor runs from mounting position and back to mounting position.

At its user interface, MVA003E has a red LED, which are described in more detail in section 6. One

internal temperature sensor is used with its internal temperature controller, freeze protection control as

well as ambient temperature sensor. The sensor does have an internal default offset value of 3 Kelvin

to compensate temperature influence through hot radiators when heating is on.

MVA003E is operating with EnOcean standard EEP A5-20-01 (4BS) in either valve position or setpoint

temperature mode. In its standard configuration, the device communicates every 10 minutes with the

control unit. The room controller responds within less than one (1) second with either a new control

value in the value range 0% (valve closed) to 100% (valve maximum open) or setpoint temperature (0

... 40°C). When the setpoint changes, the actuator motor moves the motor to the new position.

When operating with the setpoint temperature, it is recommended to use a separate, external room

temperature sensor, which transmits the room temperature to the room controller, which is then

transmitted to the MVA003E (as described in A5-20-01 protocol). Without external room temperature,

the internal controller uses the sensor installed in the device (picture next page). Due to heat input

caused by the nearfield radiator situation, there are deviations between the measured and actual room

temperature, which are compensated by means of an integrated fixed temperature offset correction

function.

In the event of a radio failure (6 unsuccessful communication attempts), the actuator automatically

switches to its internal temperature control using the last received and valid temperature setpoint from

the control unit (SPS=1 operation active prior loss of radio situation). With the lack of a valid temperature

setpoint °C value (e.g. sole operation in SPS=0), the internal default value of 21°C is used. A change of

the radio interval does not take place. The device goes into normal operation as soon as the radio

communication is restored.

When operating in unheated rooms, the internal rechargeable storage will eventually be discharged.

The device then moves to the 50% position to recharge the storage. Operation in unheated rooms is not