Filtering Product

Add the desired volume of protein to the feed vessel. Record the protein1.

temperature. Follow the purge procedure. Attach the air supply and

pressurize the feed vessel to 2.07 bar (30 psi).

Place a clean, empty collection vessel beneath the device outlet port on2.

the weigh scale. Tare the scale.

Open V1 and start recording the mass of the filtrate collected at desired3.

time intervals. Stop the process (close V1) when the target conditions

(e.g. volume, flux) have been reached.

Depressurize the feed vessel and remove the air supply.4.

Post-Use Buffer Flush

(Optional for Product Recovery)

Empty the protein from the feed vessel and replace it with approximately1.

10 mL of buffer. Attach the air supply and pressurize to 2.07 bar (30 psi).

Place a clean, empty collection vessel beneath the device outlet port on

the weigh scale. Tare the scale.

Open V1 and monitor the mass of filtrate collected. Stop the process2.

(close V1) when 3 mL of buffer is collected.

Depressurize the feed reservoir and remove from the air supply.3.

Empty the feed reservoir and the collection vessel. Purge the device

(see Purging the Device) and perform an integrity test.

Integrity Testing (Optional)

Note The device must be fully wetted with water or buffer before

performing this test.

The device filtration area is approximately 3.1 cm².

The diffusional flow rate is too low to measure

accurately, therefore a gross pass/fail integrity test is

recommended.

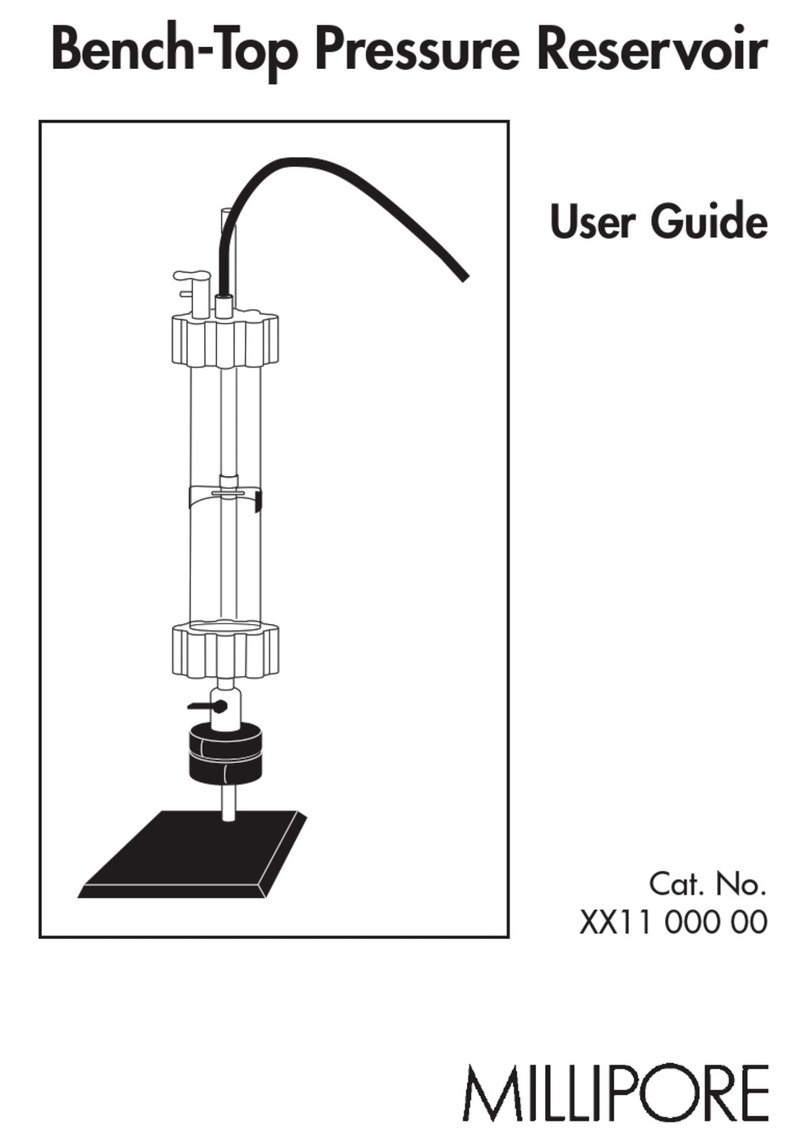

Place a beaker of water beneath the outlet port of1.

the device. Attach one end of the filtrate tubing to

the outlet port and immerse the other end in the

beaker of water.

Attach the air supply to the feed vessel. Open the2.

inlet air valve and pressurize the system to 0.3 bar

(5 psi). Open V1 and V2 to drain any liquid. Close V2. Increase pressure

to 3.5 bar (50 psi).

After five minutes have elapsed, watch for bubbles exiting the immersed3.

filtrate tubing. After observing for one minute, no bubbles should be

visible exiting an integral device.

Slowly release the pressure in the feed vessel and close V1.4.

Note Rapid depressurization after integrity testing may damage

the device.

Disconnect the device. If the device is integral, discard it. If the device5.

is not integral, store it in a beaker of 2 to 8° C water and notify your

Millipore representative.

Flushing and Wetting

Milli-Q water, WFI or equivalent is required to wet and flush the filters.

After purging the device, attach an air supply to the feed reservoir.1.

Pressurize the system to 2.07 bar (30 psi).2.

Tare the weigh scale.3.

Open V1 and start recording the elapsed time and the weight of the4.

filtrate collected. Record the weight every minute, for at least ten minutes,

until a stable flow rate is observed for three consecutive minutes. Close

V1 to stop the flow. Record fluid temperature. Calculate the temperature

corrected flow rate (Q25° C )for water (see Flow Rate Calculation).

Depressurize the system and remove the air supply. Empty the feed5.

vessel. Open V1 to ensure all liquid is drained from the device.

Close V1.

Measuring Buffer Flux

Fill the feed vessel with buffer. Record the temperature of the buffer.1.

Purge the device (see Purging the Device). Attach the air supply and

pressurize the feed reservoir to 2.07 bar (30 psi).

Place a clean, empty collection vessel beneath the device outlet port on2.

the weigh scale. Tare the scale.

Open V1 and start recording elapsed time and the mass of the filtrate3.

collected. Record the mass every minute for at least ten minutes. Close

V1 to stop flow. Record the fluid temperature. Depressurize the feed

reservoir.

Calculate the4. Q25° C for the buffer (see Flow Rate Calculation).

Empty the remaining buffer from the feed reservoir.5.

Flow Rate Calculation

Flow Rate at 25 °C and 2.07 bar (30 psi): 1.1 to 3.9 mL/min.

Calculate the temperature-corrected flow rate (Q25° C ) using the following

equation:

Q

25° C = Qp*F

Where:

Qpis the filtrate flow rate in mL/ min. (may assume a density of

1 g/cc for water to convert weight to volume)

F is the Temperature Correction Factor from Table 1.

Table 1. Temperature Correction Factor (F)*

T (°F) T (°C) F T (°F) T (°C) F T (°F) T (°C) F

104.0 40 0.734 82.4 28 0.935 60.8 16 1.243

102.2 39 0.748 80.6 27 0.956 59.0 15 1.276

100.4 38 0.762 78.8 26 0.978 57.2 14 1.310

98.6 37 0.777 77.0 25 1.000 55.4 13 1.346

96.8 36 0.793 75.2 24 1.023 53.6 12 1.383

95.0 35 0.808 73.4 23 1.047 51.8 11 1.422

93.2 34 0.825 71.6 22 1.072 50.0 10 1.463

91.4 33 0.842 69.8 21 1.098 48.2 9 1.506

89.6 32 0.859 68.0 20 1.125 46.4 8 1.551

87.8 31 0.877 66.2 19 1.152 44.6 7 1.598

86.0 30 0.896 64.4 18 1.181 42.8 6 1.648

84.2 29 0.915 62.6 17 1.212 41.0 5 1.699

*Based on Water Fluidity Relative to 25 ºC (77 ºF)

Fluidity Value F=

(μT ºC/μ25 ºC)

or

(μT ºF/μ77 ºF)

If the device does not meet the specification listed above, check the water

temperature and pressure and repeat the Q25° C measurement. If the value

falls outside the recommended range stated above, replace the device and

start over.

Note If the device does not meet specification, store in a beaker of

2 to 8 °C water and notify your Millipore representative.

Figure 2. Integrity Test