The M logo, Millipore, and Durapore are registered trademarks of Merck KGaA, Darmstadt, Germany.

Fluoropore and MF-Millipore are trademarks of Merck KGaA.

© 2015 EMD Millipore Corporation. Billerica, MA, U.S.A. All rights reserved.

M12194, Rev. 12/15

Make sure that any tubing used is autoclavable and can withstand the maximum

filtering pressure.

Acceptable tubing: pure gum rubber, silicone rubber, PTFE-lined tubing

Unacceptable tubing: surgical latex, black rubber compounds

1. Make sure that all inner surfaces of the filter holder are completely dry, then

assemble the holder with a filter in place. Hand tighten the locking ring.

2. Screw on the top cap, but do not fully tighten.

3. Wrap the exposed ends of the filter holder with lint-free autoclave paper

and secure with autoclavable tape or a rubber band. If desired, a length of

autoclavable tubing not exceeding 1.5 meters (5 feet) can be attached to the

outlet tube.

4. Autoclave the filter holder at 121 °C 1 bar (15 psi) for 25minutes. Allow the

filter holder to cool, then tighten the locking ring using the wrenches provided.

Checking System Integrity (Optional)

A wet membrane filter will not allow gas to pass through the pores at any pressure

below a critical value. You can detect a damaged filter or assembly leak with the

following test:

1. Attach a short length of flexible tubing to the holder outlet, and place the end

of the tubing in a glass beaker or other open receptacle. Place enough water in

the beaker to cover the open end of the tubing.

2. Pour a small amount of the liquid you want to filter into the filter holder barrel.

Screw down the top cap, connect pressure tubing, and apply low pressure

~ 0.2bar (~ 3 psi). All liquid above the filter will pass through to the beaker, and

flow should then stop. If no bubbles are seen, skip to step 4. Bubbles or a rapid

continuous flow of gas exiting the outlet tubing indicate inadequate wetting,

filter failure, or incomplete sealing.

3. If bubbles are seen, first try rewetting the filter (step 2). If the same thing

happens, disassemble the system, inspect membrane for damage, and ensure

that there is no dirt, debris, or damage to the O-ring or sealing surface. Install a

new filter and repeat loading, autoclaving, and system integrity steps 1 and 2.

4. Slowly increase pressure, in 0.3 bar (5 psi) increments to approximately 80% of

the bubble point pressure for the installed filter. Typical bubble points can be

found at www.millipore.com. Enter the family name (Durapore, MF-Millipore,

Fluoropore, etc. + membrane filters) in the search box. Continue to increase

pressure in 0.3 bar (5 psi) increments, pausing 10–15 seconds after each

increase. The test is successful if you reach or exceed the typical bubble point.

NOTE: If the holder contains multiple filters (as in a serial filtration), or a

prefilter in addition to the membrane filter, gas trapped against the wet

membrane after a bubble point test can produce an air-lock that will

restrict flow. You can overcome this by raising the filtering pressure over

the bubble point of the smallest pore size filter used.

Filtering the Sample

NOTE: If the system has been autoclaved, use aseptic technique.

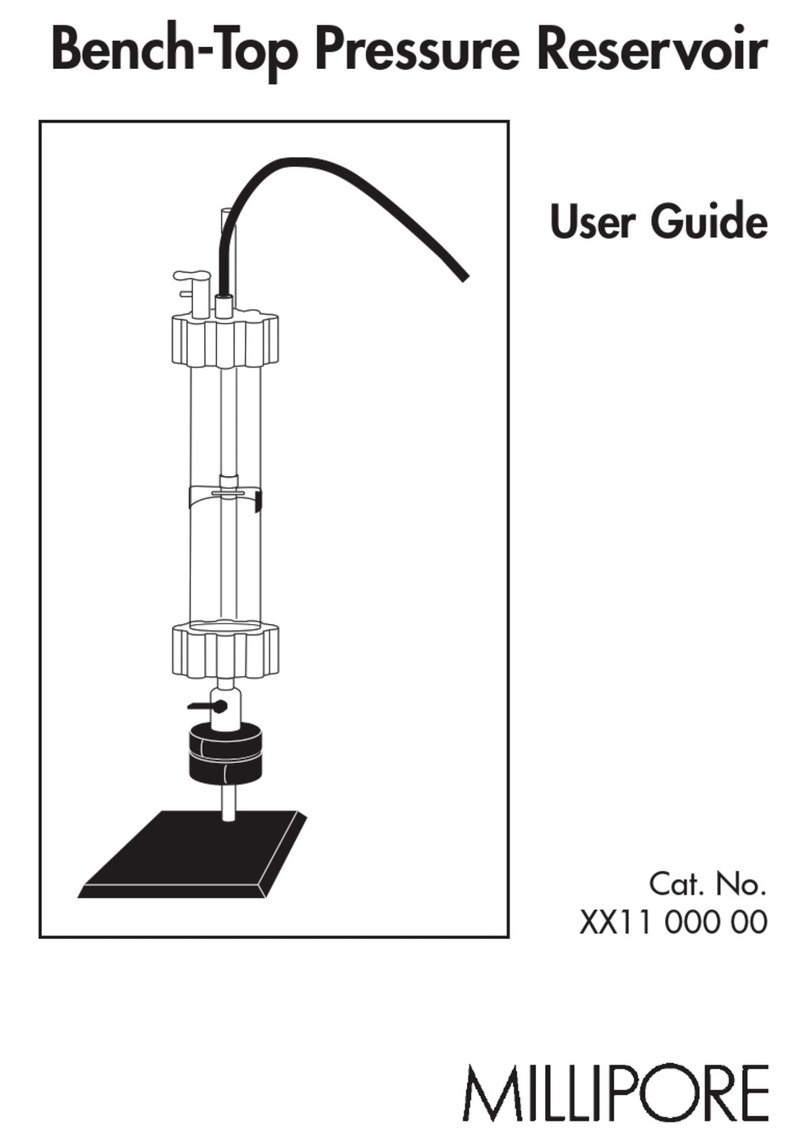

1. Place the assembled filter holder on a ring stand and place a suitable receiving

vessel under the filter holder outlet to collect the filtrate.

CAUTION: When using the silicone stopper attached to the base to seat the

filter holder in a flask receiving vessel, air must be allowed escape

from the flask during filtration.

2. Remove the top cap, if attached, and pour the sample into the holder barrel,

Screw the top cap down tightly. Attach pressure tubing to the top cap tubing

adapter using a hose clamp, and apply pressure from an inert gas or filtered air

supply to filter the sample. Do not exceed the maximum recommended pressure

of 6.9 bar (100 psi).

3. When filtration is complete, relieve internal pressure in the holder with the

regulator valve on the pressure source. If the regulator valve does not allow for

such venting, do not attempt to remove the pressure hose connection. Instead,

slowly unscrew the top cap until you hear the sound of gas escaping. When the

sound ceases, remove the pressure tubing and open the holder.

Specifications

Maximum pressure 6.9 bar (100 psi) inlet and differential

Filter diameter 47 mm

Prefilter diameter 42 mm (thick depth prefilter)

Effective filter area 14.3 cm2(2.2 in2)

Capacity 100 mL (cat. no. XX4004700) and

340 mL (cat. no. XX4004740)

Connections Inlet: 3/8 in. tubing adapter

Outlet: accepts 1/4in. to 3/8 in. inner diameter flexible tubing

Dimensions Diameter (locking ring): 6.9 cm (2.7 in.)

Height (XX4004700): 28.1 cm (11.1 in.)

(XX4004740): 52.5 cm (20.7 in.)

Weight XX4004700: 1.1 kg (2.3 lb)

XX4004740: 1.2 kg (2.7 lb)

Materials of

construction

Top cap, barrel, filter support screen, base: stainless steel

Locking ring and wrenches: anodized aluminum

Filter O-ring and locking ring gasket: PTFE

Top cap O-ring: fluoroelastomer

Stopper: silicone

Typical Filter Flow Rates

For typical flow rates and available microporous membrane filters, go to

www.millipore.com and enter the family name (Durapore, MF-Millipore, Fluoropore,

etc. + membrane filters) in the search box.

Statement Regarding Compliance with the Pressure

Equipment Directive, 97/23/EC

EMD Millipore Corporation certifies that this product complies with the European

Pressure Equipment Directive, 97/23/EC of 29 May 1997. This product is classified

under Article 3 § 3 of the Pressure Equipment Directive. It has been designed and

manufactured in accordance with sound engineering practices to ensure safe use.

The product is accompanied by user instructions and bears markings to permit

identification of EMD Millipore Corporation as the manufacturer or authorized

representative of this product within the European Community. In compliance with

Article 3 § 3 of the Pressure Equipment Directive, this product does not bear the

CEmark.

Product Ordering Information

This section lists catalogue numbers for the Stainless Steel 47 mm Pressure Filter

Holder, spare parts, and accessories. See the Technical Assistance section for

contact information. You can purchase these products on-line at

www.millipore.com/products.

Description Qty

Catalogue

Number

Stainless Steel In-line Filter Holder, 100 mL 1 XX4004700

Stainless Steel In-line Filter Holder, 340 mL 1 XX4004740

Top cap with hose adapter 1 000205

Locking ring gasket 5 XX4004714

Filter sealing O-ring 5 XX4004716

Filter support screen 1 XX4004704

Silicone stopper, 9.5 mm (3/8 in.) hole 5 XX2004718

Replacement parts kit, 47 mm holder (includes top cap

O-rings [5], locking ring gaskets [5], filter sealing O-rings [5])

1 XX40047RK

Accessories

Filter forceps, stainless steel, blunt end (3/pk) 1 XX6200006P

PVC tubing (not autoclavable), 9.5 mm (3/8 in.) inner

diameter × 3 meters (10 ft), with 2 stainless steel clamps

1 XX6700034

Vacuum/pressure pump, 115 V, 60 Hz 1 WP6111560

Vacuum/pressure pump, 230 V, 50 Hz 1 WP6122050

Vacuum/pressure pump, 100 V, 50/60 Hz 1 WP6110060

Notice

The information in this document is subject to change without notice and should

not be construed as a commitment by EMD Millipore Corporation (“Millipore”) or

an affiliate. Neither EMD Millipore Corporation nor any of its affiliates assumes

responsibility for any errors that may appear in this document.

Technical Assistance

For more information, contact the office nearest you. In the U.S., call

1-800-221-1975. Outside the U.S., go to our web site at www.millipore.com/offices

for up-to-date worldwide contact information. You can also visit the tech service

page on our web site at www.millipore.com/techservice.

Standard Warranty

The applicable warranty for the products listed in this publication may be found at

www.millipore.com/terms (“Conditions of Sale”).

Specifications, continuedAutoclaving, continued

M12194_Rev1215.indd 2 12/22/2015 8:41:32 AM