Milwaukee HEAVY DUTY M12 BLROT User manual

Other Milwaukee Power Tools manuals

Milwaukee

Milwaukee 2630-20 User manual

Milwaukee

Milwaukee M18 FUEL 2749-20 User manual

Milwaukee

Milwaukee K900K User manual

Milwaukee

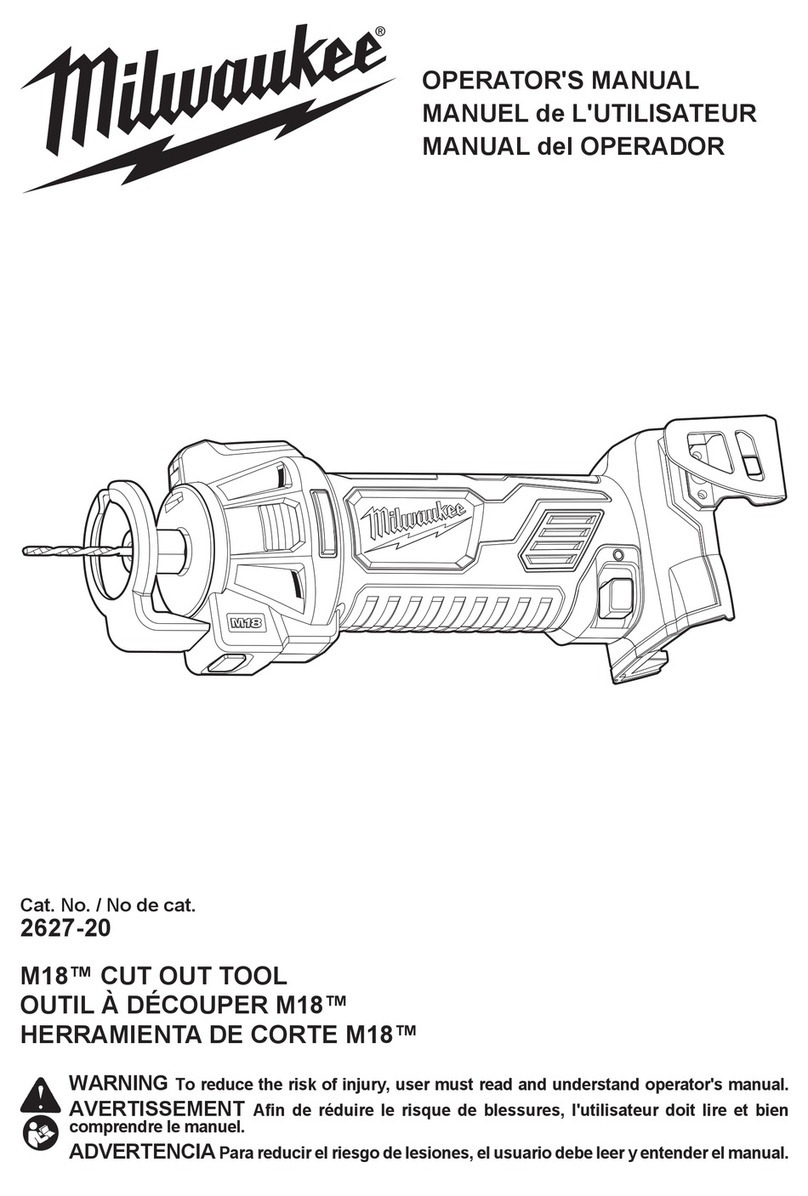

Milwaukee 2627-20 User manual

Milwaukee

Milwaukee M18BMT-0 User manual

Milwaukee

Milwaukee M18 FUEL FPMC User manual

Milwaukee

Milwaukee M18 User manual

Milwaukee

Milwaukee M18 BMT User manual

Milwaukee

Milwaukee 6268-21 User manual

Milwaukee

Milwaukee M12 FIR14 User manual

Milwaukee

Milwaukee M18 User manual

Milwaukee

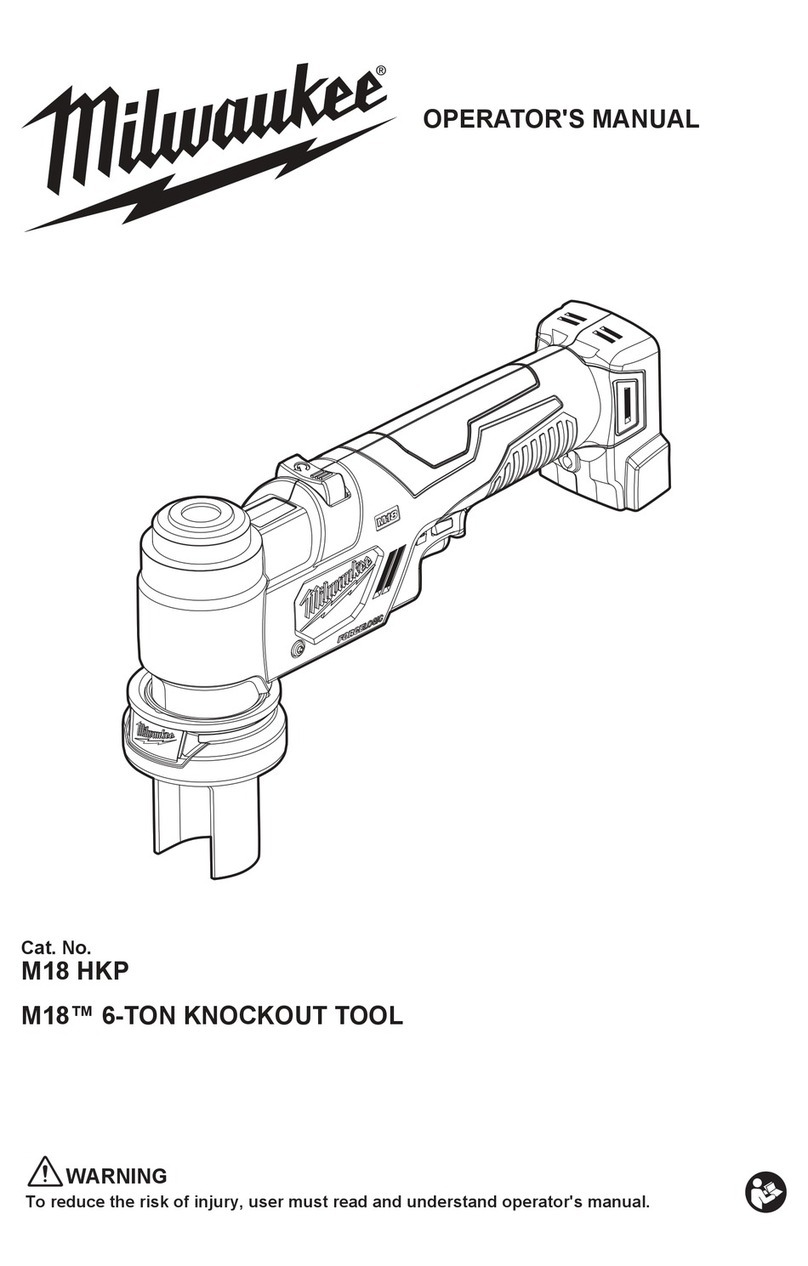

Milwaukee M18 HKP User manual

Milwaukee

Milwaukee HD18 JSB User manual

Milwaukee

Milwaukee M18 FFN User manual

Milwaukee

Milwaukee M18 ROCKET User manual

Milwaukee

Milwaukee 6853 User manual

Milwaukee

Milwaukee M12 DCAG User manual

Milwaukee

Milwaukee M18 User manual

Milwaukee

Milwaukee HD28 SG User manual

Milwaukee

Milwaukee K?500?ST User manual