Contents

INTRODUCTION......................................................................................................................................................I

PICTOGRAMS AND CONVENTIONS USED IN THIS MANUAL ...........................................................................I

POSITIONING OF THIS DOCUMENT.....................................................................................................................I

REVISION HISTORY...............................................................................................................................................II

CONTENTS............................................................................................................................................................III

1. OVERVIEW......................................................................................................................................................1

1-1. Features ...............................................................................................................................................1

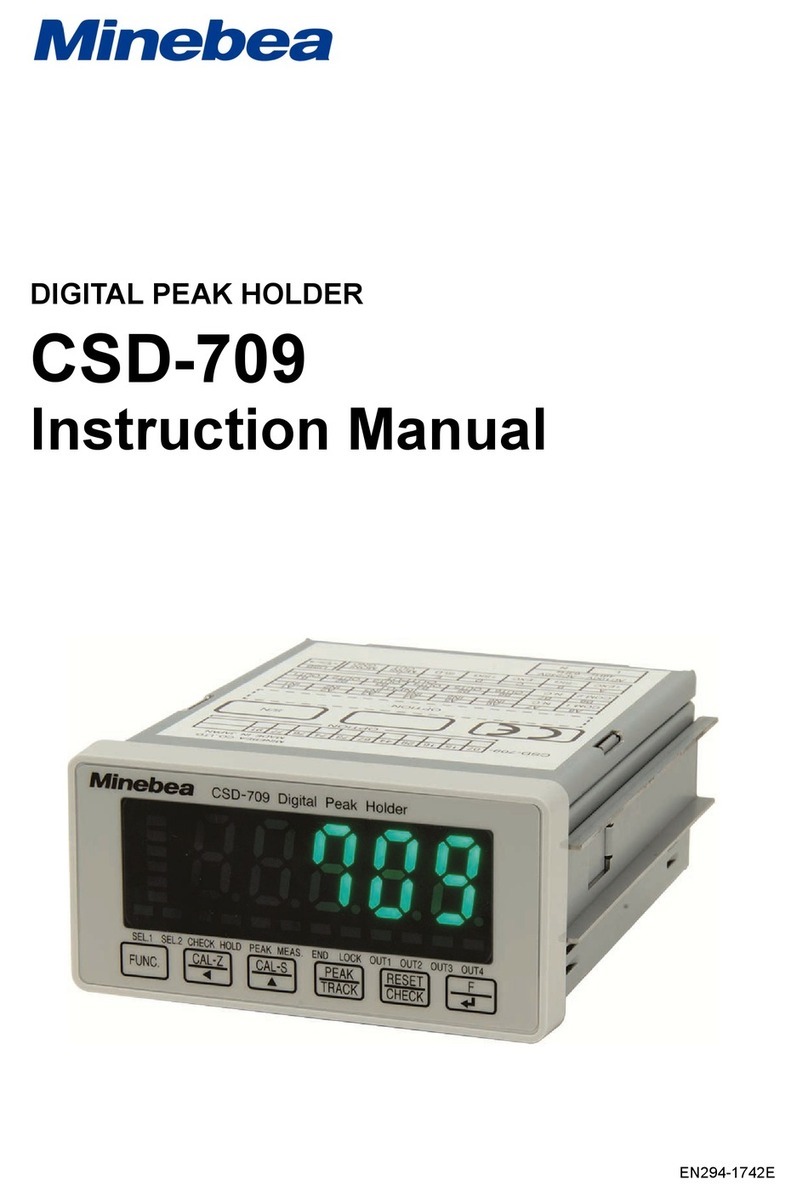

2. PART NAMES AND FUNCTIONS...................................................................................................................1

2-1. Front panel ...........................................................................................................................................1

3. EQUIPMENT WIRING .....................................................................................................................................2

3-1. Communication connector pin configuration........................................................................................2

3-2. Connection Method ..............................................................................................................................2

4. MODBUS COMMUNICATION SETTINGS......................................................................................................3

4-1. Setup Screen........................................................................................................................................3

4-2. Modbus Settings...................................................................................................................................4

5. COMMUNICATION PACKETS........................................................................................................................5

5-1. Available Function Codes.....................................................................................................................5

5-2. Operation Example: Fetching 2 Bytes of Data.....................................................................................6

5-3. Operation Example: Fetching 4 Bytes of Data.....................................................................................6

5-4. Operation Example: Fetching at Least 8 Bytes of Data .......................................................................7

5-5. Error Response ....................................................................................................................................7

5-6. CRC Calculation...................................................................................................................................7

6. ADDRESS LIST...............................................................................................................................................8

6-1. Reading Control I/O Status (Read Coils) .............................................................................................8

6-2. Reading Alarm/Error Status (Read Discrete Inputs) ............................................................................8

6-3. Reading Shot Count and Time (Read Input Register)..........................................................................8

6-4. Reading Measurement (Read Input Register) .....................................................................................9

6-5. Reading Amplifier Version Information and Configuration (Read Holding Register)..........................10

6-6. Reading Common Settings (Holding Register) ..................................................................................11

6-7. Modbus Communication Specifications .............................................................................................11