JY997D24901A

Safety Precaution

(Read these precautions before use.)

This manual classifies the safety precautions into two categories:

and .

Depending on circumstances, procedures indicated by may also

cause severe injury.

It is important to follow all precautions for personal safety.

Associated Manuals

How to obtain manuals

For product manuals or documents, contact with the Mitsubishi Electric dealer you

purchased your product.

Indicates that incorrect handling may cause hazardous

conditions, resulting in death or severe injury.

Indicates that incorrect handling may cause hazardous

conditions, resulting in medium or slight personal injury or

physical damage.

Manual name Manual No. Description

FX3U Series

User’s Manual

- Hardware Edition

JY997D16501

MODEL CODE:

09R516

Describes FX3U Series PLC

specification details for I/O, wiring,

installation, and maintenance.

FX3U/FX3UC Series

Programming Manual

- Basic & Applied

Instruction Edition

JY997D16601

MODEL CODE:

09R517

Describes PLC programming for

basic/applied instructions and

devices.

FX3U-32DP

User’s Manual JY997D25201

Describes details for the FX3U-

32DP PROFIBUS-DP Interface

Block, i.e. wiring, installation,

specification and BFM allocations.

FX3U-64DP-M

User’s Manual JY997D19201

Describes details for the FX3U-

64DP-M PROFIBUS-DP Master

Block, i.e. wiring, installation,

specification and BFM allocations.

GX Configurator-DP

Configuration System

for Open Networks

Software Manual

−

Describes the operation of GX

Configurator-DP Configuration

System for Open Networks

Software.

Certification of UL, cUL standards

The following product has UL and cUL certification.

UL, cUL File Number:E95239

Models: MELSEC FX3U series manufactured

FX3U-32DP

Compliance with EC directive (CE Marking)

This document does not guarantee that a mechanical system including this product will

comply with the following standards.

Make sure to have a user/system engineer check the entire mechanical systems

comformity to the EMC and LVD directives.

For more details, please contact your local Mitsubishi Electric branch office.

Requirement for the compliance with EMC directive

The following product complies with the European Directive (89/336/EEC)

Electromagnetic Compatibility by the direct testings (based on the following standard)

and design analysis (by creating a technical construction file) when the following

devices’s application follows the directions in this document.

Type: Programmable Controller (Open Type Equipment)

Models: MELSEC FX3U series manufactured

from March 1st, 2007 FX3U-32DP

Cautions for compliance with EC Directive

1) Wiring

To avoid malfunctions by noise, lay the twisted-pair PROFIBUS cable so that more

than 50 mm (1.97") is touching the grounding plate connected to the ground

terminal.

→ For details on wiring, refer to Section 3.2

2) Installing in an enclosure

→ For detail on installing in an enclosure, refer to

FX3U User’s Manual - Hardware Edition.

1. Introduction

The FX3U-32DP PROFIBUS-DP Interface Block (hereinafter called 32DP) enables

users to integrate the MELSEC FX3U PLC into any existing PROFIBUS-DP network

(DP-V0/DP-V1) as a DP-Slave. The 32DP links the FX3U PLC with PROFIBUS-DP

decentralized control tasks. The module connects the PLC system to the DP-Master in

the PROFIBUS-DP network for efficient and easy data exchange.

1) Easy Connectivity to an existing PROFIBUS-DP Network

The 32DP enables the FX3U PLC to fit into an existing PROFIBUS-DP Network as

a DP-Slave, while reducing the time and cost for users to build up a new network

system.

2) Enhanced Data Exchange

The 32DP has enhanced the data exchange functionality in the following

communication formats.

•Cyclic I/O data - a maximum of 144 Bytes

•Acyclic I/O Data - a maximum of 140 Bytes

•User-Diagnostic Messages

•Alarm(Status) Messages

3) Global control

The 32DP supports SYNC / UNSYNC / FREEZE / UNFREEZE global controls.

4) Flexible and Easy Network Setting

The 32DP enables a flexible and smooth integration with components on a new/

existing PROFIBUS-DP Network. The FX3U-32DP PROFIBUS Interface Block is

fully applicable for the user-specific PROFIBUS-DP Network.

→ For operation details of software, GX Configurator-DP

Software Manual

5) Various Communication Speed Options

The 32DP supports the communication speeds, 9.6k, 19.2k, 45.45k, 93.75k,

187.5k, 500k, 1.5M, 3M, 6M and 12Mbps to fit into various kinds of networks. To

connect the 32DP to a PROFIBUS-DP Network, use the standard 9-pin D-SUB

connector and shielded twisted-pair PROFIBUS cable complying with EN50170.

Standard Tests

EN61131-2:2003

Programmable controllers

- Equipment requirements and

tests

The corresponding items are tested on the 32DP

as follows.

• Radiated Emissions

• Mains Terminal Voltage Emissions

• RF immunity

• Fast Transients

• ESD

• Conducted

• Surge

• Power magnetic fields

1.1 Incorporated Items

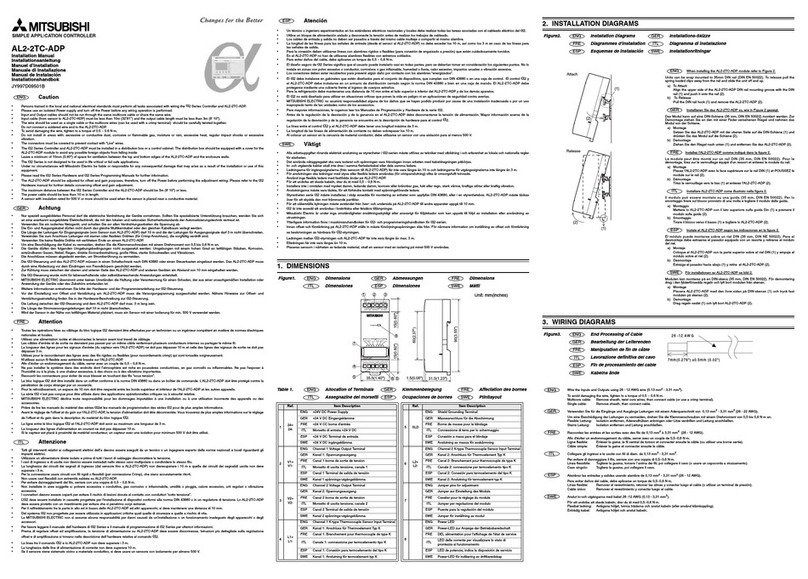

1.2 External Dimensions and Part Names

Dimensions: mm (inches) MASS (Weight): Approx. 0.2kg (0.44 lbs)

1.3 Pin configuration of PROFIBUS-DP Connector

The connector is a 9-pin D-SUB (#4-40unc inch screw thread) type, with the

following pin assignment.

2. Installation

2.1 Installation Arrangements

The 32DP is connected to the extension port of an FX3U series PLC or extension

unit/block (including special function unit/block) on the right side.

Since additional extension devices can be added on both the left and right-hand

sides of the PLC, keep an appropriate amount of space on both sides of the PLC

when planning to add extension devices in the future.

For further details on installation arrangements, refer to the following manual.

→ FX3U Series User's Manual - Hardware Edition

2.2 Mounting

The 32DP can be mounted on a DIN rail (DIN46227) or mounted directly to the

mounting surface with screws.

→ FX3U-32DP User's Manual

→ FX3U Series User's Manual - Hardware Edition

2.2.1 Direct Mounting

The 32DP can be directly mounted with M4 screws.

An interval space of 1 to 2 mm (0.04” to 0.08”) between each unit is necessary.

→ For details on the mounting hole pitch, refer to Section 1.2

2.2.2 DIN Rail Mounting

The 32DP can be mounted on a DIN rail (DIN46227, 35mm width).

1) Fit the upper edge of the DIN rail mounting

groove (right fig. A) onto the DIN rail.

2) Push the product onto the DIN rail.

3) Connect the 32DP’s extension cable to the

extension port of the main unit, I/O extension

unit/block, or special function unit/block.

→ FX3U Series User's Manual

- Hardware Edition

Product FX3U-32DP PROFIBUS-DP Interface Block

Included Items

•Manual

•Dust Proof Sheet

•GSD file (CD-ROM)

•Special Unit/Block No. Label

[1] PROFIBUS-DP port (9-pin D-SUB Connector: #4-40unc inch screw thread)

[2] Extension cable

[3] Direct mounting hole:2 holes of φ4.5 (0.18") (mounting screw: M4 screw)

[4] Status LED

[5] Extension port under the top cover

[6] Name plate

[7] DIN rail mounting groove (DIN rail: DIN46277)

[8] DIN rail mounting hook

43(1.7")

9(0.36")

90(3.55")

80(3.15")

4(0.16")

2-φ4.5

87(3.43")

89(3.51")

[7]

[8]

[5] [6][3] [4]

[2]

[1]

LED Name Color Description

POWER Green

ON: Correct power supply from the PLC

→ For other status, refer to FX3U-32DP

User's Manual

FROM/TO Green ON: Constant FROM/TO access within 200ms

intervals

RUN Green

ON: In cyclic data exchange mode

Flashing: DP-Master is in clear mode, or DP-Slave is

in Fail/Safe state.

DIA Red

OFF: Normal Operation without errors

Otherwise: An error detected

→ For error details, refer to FX3U-32DP

User's Manual

TOKEN Green ON: Estabilished connection with the DP-Master

Pin No. Signal Name Meaning

3 RXD/TXD-P Receive/Transmit-Data-P

4 RTS Ready to send

5 DGND Data Ground

6 VP Voltage-Plus (5V, 90mA)

8 RXD/TXD-N Receive/transmit-Data-N

1, 2, 7, 9 NC Pin not assigned

Assigned

Not assigned

67 98

12 3 54

INSTALLATION

PRECAUTIONS

•Cut off all phases of the power supply externally before installation or wiring

work in order to avoid damage to the product or electric shock.

INSTALLATION

PRECAUTIONS

•Use the product within the generic environment specifications described in the

PLC main unit manual (Hardware Edition).

Never use the product in areas with excessive dust, oily smoke, conductive

dusts, corrosive gas (salt air, Cl2, H2S, SO2or NO2), flammable gas, vibration

or impacts, or exposed to high temperature, condensation, or rain and wind.

If the product is used in such conditions, electric shock, fire, malfunctions,

deterioration or damage may occur.

•Install the product securely using the DIN rail or screws.

•Install the product on a flat surface.

If the mounting surface is rough, undue force will be applied to the PC board,

thereby causing nonconformity.

•When drilling screw holes or wiring, make sure cutting or wiring debris does not

enter the ventilation slits.

Failure to do so may cause fire, equipment failures or malfunctions.

•Be sure to remove the dust proof sheet from the PLC's ventilation port when

installation work is completed.

Failure to do so may cause fire, equipment failures or malfunctions.

•Connect the extension cables and communication cables securely to the

designated connectors.

Contact failures may cause malfunctions.

•Do not touch the conductive parts of the product directly to avoid failure or

malfunctions.

1)

2)

A

FX3U-32DP

INSTALLATION MANUAL

Before installation, operation, maintenance or inspection of this product,

thoroughly read through and understand this manual and the associated

manuals. Also, take care to handle the module properly and safely.

Store this manual in a safe place so that it can be taken out and read whenever

necessary. Always forward it to the end user.

Registration

The company name and the product name to be described in this manual are

the registered trademarks or trademarks of each company.

Effective March 2007

Specifications are subject to change without notice.

©2007 Mitsubishi Electric Corporation

Manual Number JY997D24901

Revision A

Date March 2007