User Instructions

Should you nd your equipment is no longer of use,

please dispose of in a responsible manner. Please

contact Modulift if you need further guidance

Table 2 – Load v Span

© Copyright 2015 Modulift.

All rights reserved.

User Instructions

Do’s & Don’ts

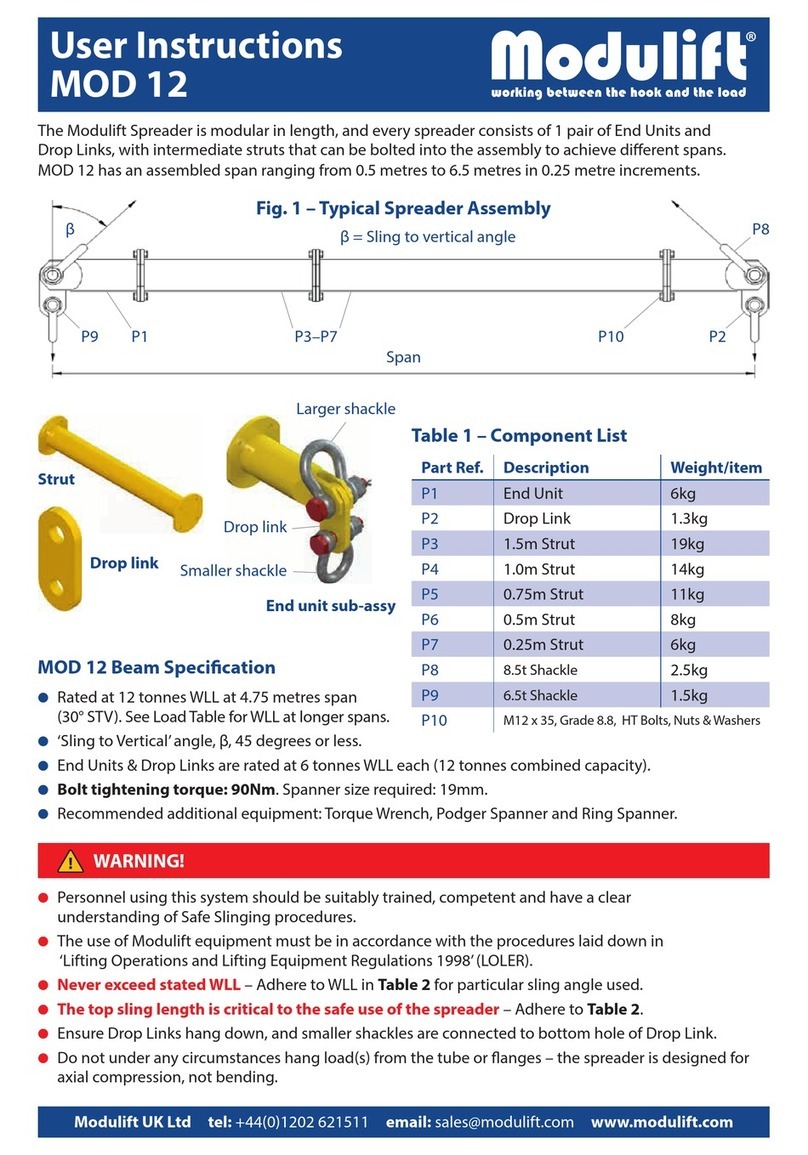

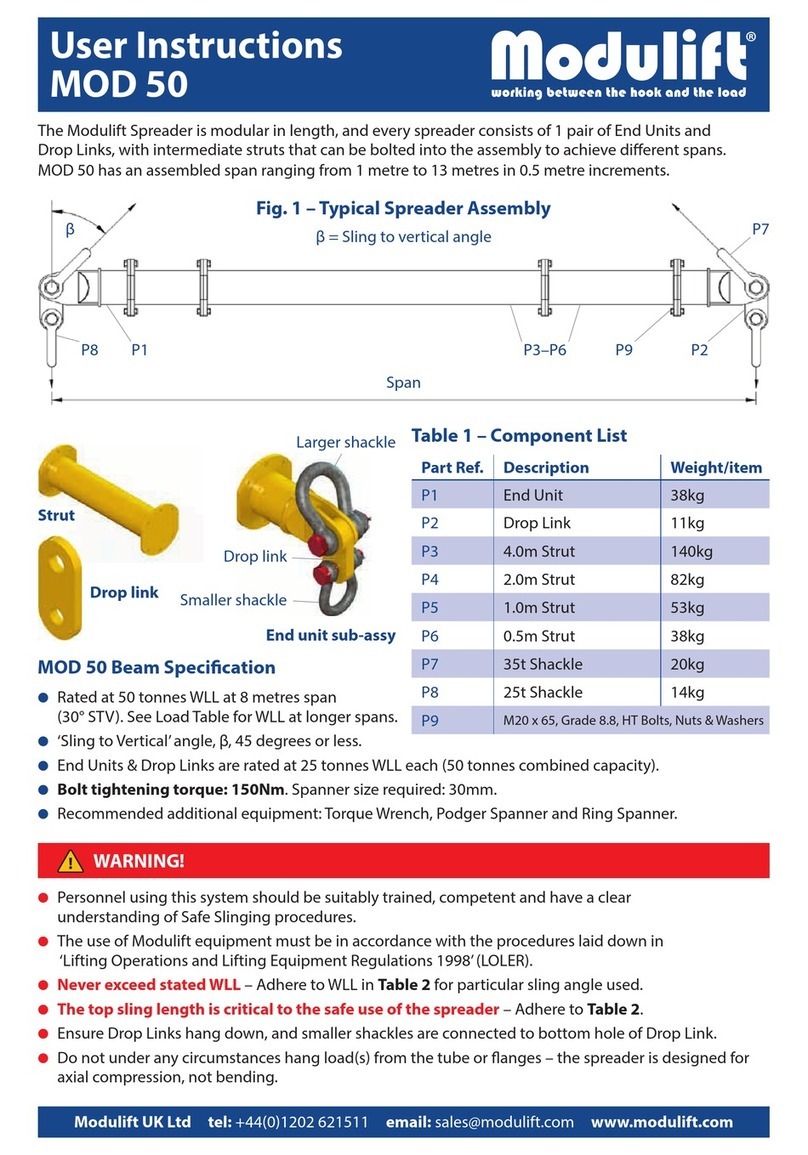

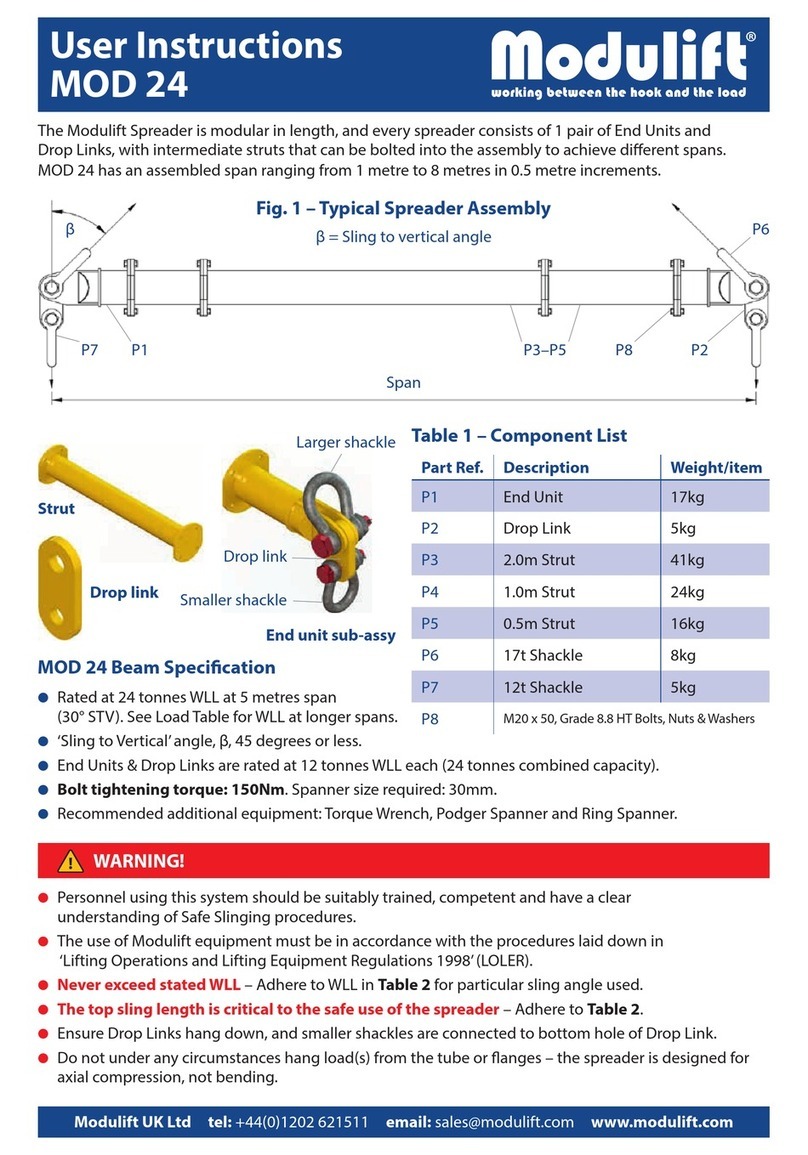

● Do ensure to load the spreader through the main trunnion

pin only. i.e. adhere to Fig. 1.

● Do keep the loaded spreader clear of obstacles

– any contact could cause beam failure.

● Do ensure correct use of appropriate top slings, do not twist

any slings unnecessarily.

● Do not hang any load from the spreader tube or anges.

● Do not exceed stated SWL for that particular span

– adhere to Table 2.

● Do not rig the lower slings less than 45 degrees BSA.

● When moving or positioning long struts or assemblies use

tag lines to control movement.

● Individual components can be heavy and extreme care must

be taken if manual handling.

Recommended top sling types:

Textile slings, cable laid wire rope slings or grommets.

Slings must have soft eyes. Always ensure clearance between

the sling and end unit.

Note: Lengthening the slings can give greater clearance.

Refer to Modulift supplier if in doubt.

Assembly Procedure

Please refer to separate assembly and setup

procedure for more information.

WARNING!

TRUN MOD 250/400 US SEP 2015

● The rigger must ensure that there is a clearance between

the sling end tting and the end unit as shown above.

● Max number of struts allowed in spreader assembly: 6.

● Assemble longer struts in the centre of the spreader

conguration.

● Sling angle is crucial to safe use of spreader.

Span

(ft)

Base to Sling

Angle (BSA) αRecommended Conguration

EU - End Unit (3ft)

To calculate the SWL at intermediate spans utilising

the 1ft strut, round up the span to the next

longest span inTable 2, and use the stated SWL.

60°

SWL

metric tons

(tonnes)

Min.top

sling

length

(ft in)

6400 6 EU EU

8400 8 EU 2 EU

10 400 10 EU 3 1 EU

12 400 12 EU 5 1 EU

14 400 14 EU 5 3 EU

16 400 16 EU 10 EU

18 400 18 EU 10 2 EU

20 400 20 EU 3 10 1 EU

22 400 22 EU 5 10 1 EU

24 400 24 EU 5 10 3 EU

26 400 26 EU 10 10 EU

28 400 28 EU 20 2 EU

30 400 30 EU 3 20 1 EU

32 400 32 EU 5 20 1 EU

34 400 34 EU 5 20 3 EU

36 400 36 EU 20 10 EU

38 368 38 EU 10 20 2 EU

40 341 40 EU 10 20 3 1 EU

42 299 42 EU 10 20 5 1 EU

44 284 44 EU 10 20 5 3 EU

46 268 46 EU 20 20 EU

48 244 48 EU 20 20 2 EU

50 230 50 EU 3 20 20 1 EU

52 211 52 EU 5 20 20 1 EU

54 195 54 EU 5 20 20 3 EU

56 174 56 EU 20 20 10 EU

58 166 58 EU 10 20 20 2 EU

60 150 60 EU 10 20 20 3 1 EU

62 138 62 EU 10 20 20 5 1 EU

64 126 64 EU 10 20 20 5 3 EU

66 112 66 EU 10 20 20 10 EU

68 106 68 EU 10 20 20 10 2 EU

Clearance

TRUN MOD 250/400