4

CONGRATULATIONS ON YOUR NEW EXERCISE BIKE

designed by Monark Exercise AB, Sweden. Monark has been the worlds leading manufacturer of high

quality ergometers and exercise cycles for more than 40 years.

GENERAL

It is important that you keep your ergometer clean and properly lubricated. Most important is to protect

the chromed and zinced parts but also painted parts benefit from the same protection.

When cleaning and lubricating be sure to check that all screws and nuts are properly tightened.

Be sure that all moving parts as crank and flywheel is working normal and that no unnormal play or

sound excists. I. e. play in bearings causes fast waring and with that follows a highly reduced lifetime.

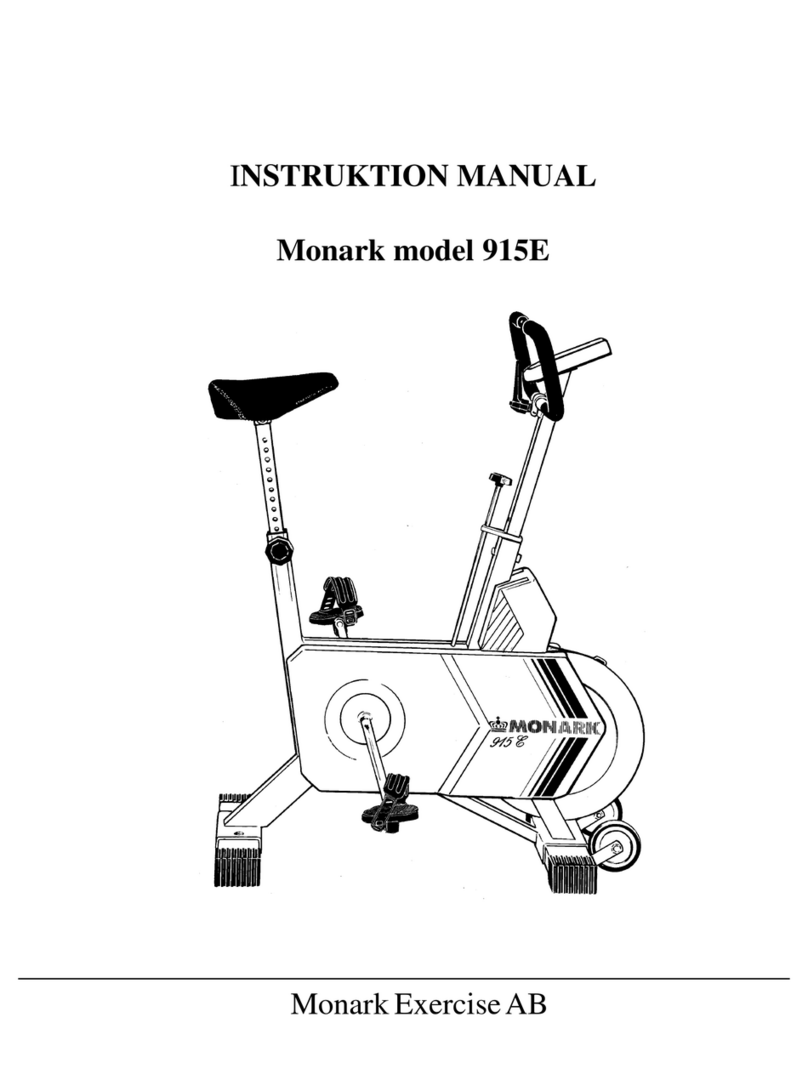

PLEASE NOTE: The production number of your exercise cycle is placed according to fig 1 page 6.

WARRANTY

As on any quality product there may be an exceptional fault due to material or manufacture. If such a

fault should arise on your exercise cycle, please return to the place of purchase for necessary repair.

Monark products and parts are guaranteed against defects in materials and workmanship for a period of

one year from the initial date of purchase of the unit.

Parts found to need replacement due to normal wear and tear, such as brake belts, are not covered. This

guarantee covers parts only, not labor costs associated with the repair.

This guarantee does not apply to cases of abuse or vandalism, nor does it extend to any injury or loss to

person or property caused directly or indirectly by any Monark products.

In the event of a defect in material or workmanship during the warranty period, Monark Exercise will

repair or replace (at its option) the product. Monark Exercise will do so at its expense for the cost of

materials but not for labour or shipping