Product User Manual HB series 4

Table of Contents

1!PREFACE ........................................................................................................................................... 6!

1.1!....!Description of the Equipment .......................................................................................................... 6!

1.2!....!Notations Used in This Manual ........................................................................................................ 6!

1.3!....!Models covered in this Manual ........................................................................................................ 6!

1.4!....!Explanation of Safety Warnings ...................................................................................................... 7!

1.5!....!Obtaining Instructions ..................................................................................................................... 7!

1.5.1!Internet ........................................................................................................................................................ 7!

1.5.2!Ordering Documentation ............................................................................................................................. 7!

1.5.3!Documentation Feedback ............................................................................................................................ 7!

2!Description of the product .............................................................................................................. 8!

2.1!....!Purpose of the Product .................................................................................................................... 8!

2.2!....!Technical Data ................................................................................................................................. 8!

2.3!....!Product Compliance ......................................................................................................................... 8!

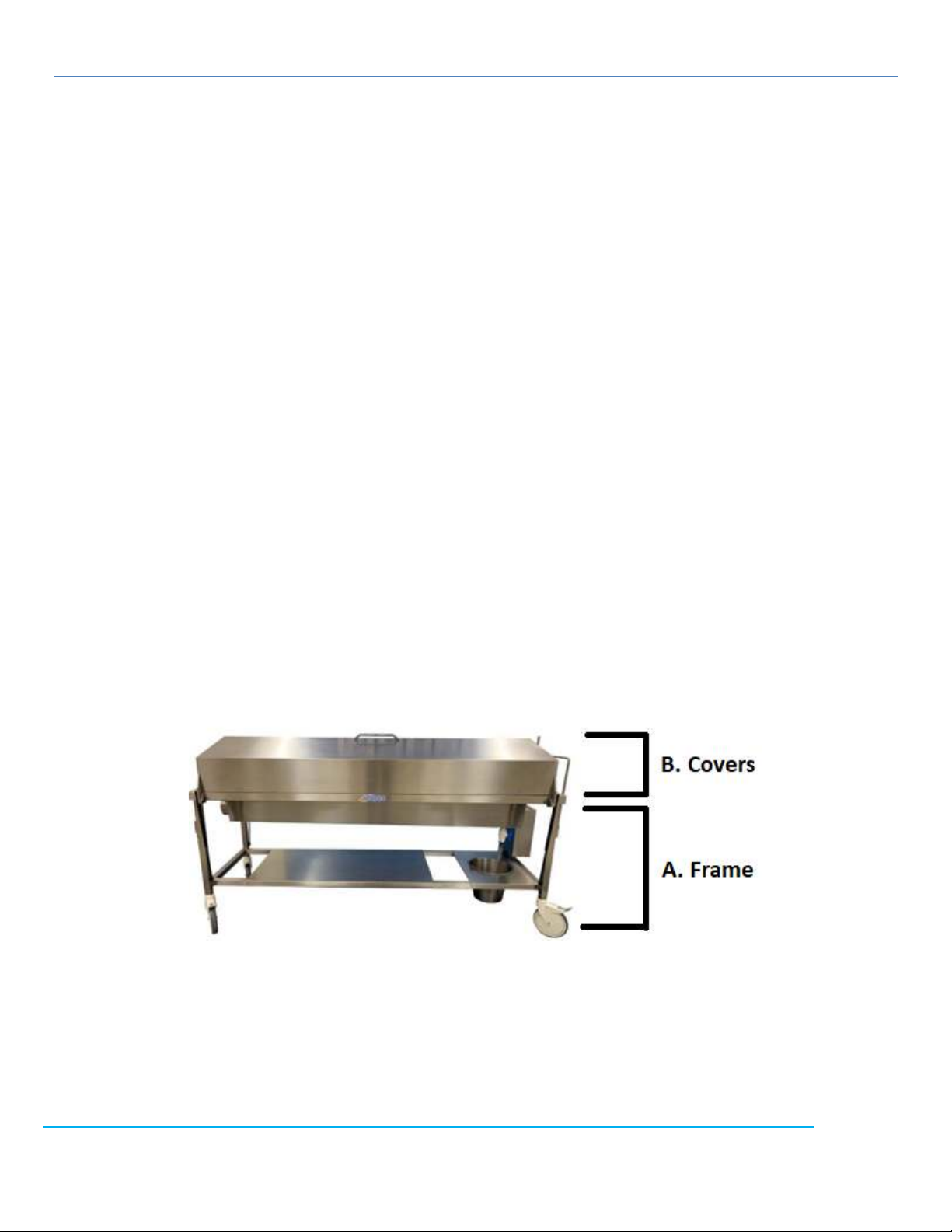

2.4!....!Product elements ............................................................................................................................. 8!

2.5!....!Warranty Statement ........................................................................................................................ 9!

3!Installation ..................................................................................................................................... 10!

3.1!....!How to unpackage your workstation ............................................................................................. 10!

3.1.1!Check for freight damage .......................................................................................................................... 10!

3.1.2!Uncrating Contents .................................................................................................................................... 10!

3.1.3!Transporting Unit to final location ............................................................................................................ 10!

3.1.4!Ventilation connection (in-house ventilation) ........................................................................................... 10!

3.2!....!Decommissioning the Unit ............................................................................................................. 10!

3.2.1!Decontaminate the unit. ........................................................................................................................... 10!

3.3!....!How to Store the Product .............................................................................................................. 11!

3.3.1!Storage in place ......................................................................................................................................... 11!

3.3.2!Storage on a skid ....................................................................................................................................... 11!

3.4!....!Disposal and Recycling ................................................................................................................... 11!

3.4.1!Stainless Steel ............................................................................................................................................ 11!

3.4.2!Plastic ......................................................................................................................................................... 11!

3.4.3!Electronics ................................................................................................................................................. 11!

4!Quick Start Guide of Misting System ............................................................................................. 12!

4.1!....!Startup ........................................................................................................................................... 12!