Operating Instructions | AirSpeed 450

2

CONTENTS

1. Introduction...............................................................................................................................................4

2. Safety Risks..............................................................................................................................................4

2.1 Warning...............................................................................................................................................4

2.2 General Work Safety and Health Protection........................................................................................4

3. Warnings ..................................................................................................................................................5

4. Technical Parameters...............................................................................................................................7

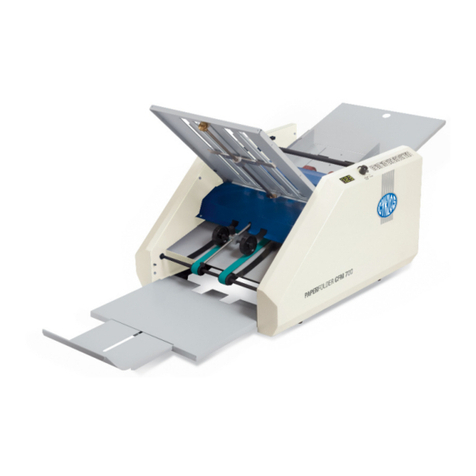

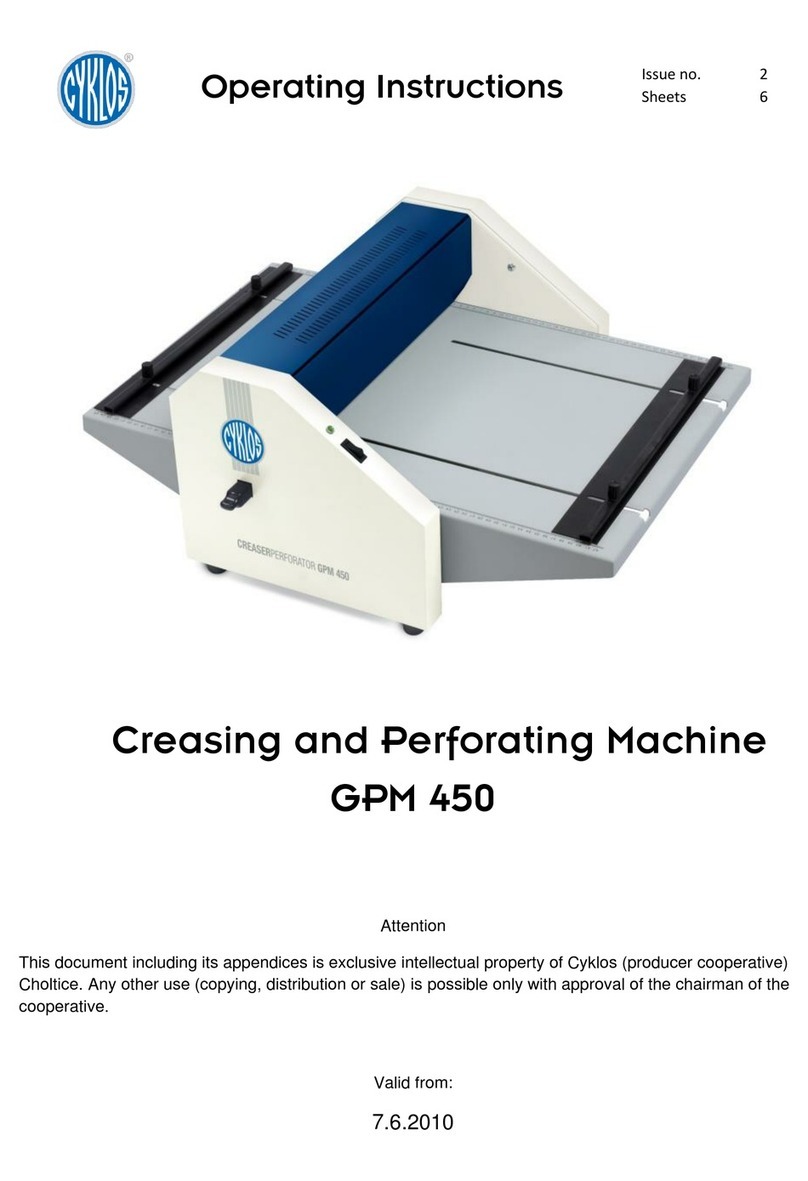

5. Machine Description .................................................................................................................................8

5.1. Introduction ........................................................................................................................................8

5.2 Exchangeable tools.............................................................................................................................9

6. Machine Installation................................................................................................................................11

7. Setting the Machine................................................................................................................................11

7.1 Setting the Table...............................................................................................................................11

7.1.1 Setting the Table Upper Position.................................................................................................13

7.2 Setting the Separator ........................................................................................................................13

7.3 Setting Air Blowers Gap ....................................................................................................................14

7.4 Setting Rotary Perforating (Cutting) and Guiding Pulleys ..................................................................14

7.4.1 Setting Perforation or Cutting Thrust...........................................................................................15

7.5 Setting Delivery Table .......................................................................................................................15

7.6 Adjustment of Top Bar Stroke............................................................................................................16

8. Setting the Machine Using Touch Screen...............................................................................................17

8.1 Touch Screen Preview......................................................................................................................17

8.2 Overview of Touch Screen Function Icons ........................................................................................17

8.2.1 Sound On/Off..............................................................................................................................17

8.2.2 Manual Control ...........................................................................................................................18

8.2.3 Info .............................................................................................................................................18

8.2.4 Language Selection....................................................................................................................18

8.2.5 Service Menu..............................................................................................................................19

8.3 Setting the Feed................................................................................................................................20

8.4 Setting the Number and Position of Creases/Perforations.................................................................21

8.4.1 Most Common Folds...................................................................................................................21

8.4.2 Setting the Number of Segments................................................................................................22

8.4.3 Setting the Position of Segments................................................................................................22

8.5 Setting the Speed of Processing .......................................................................................................23

8.6 Loading Paper...................................................................................................................................23

8.7 Setting Batch.....................................................................................................................................23