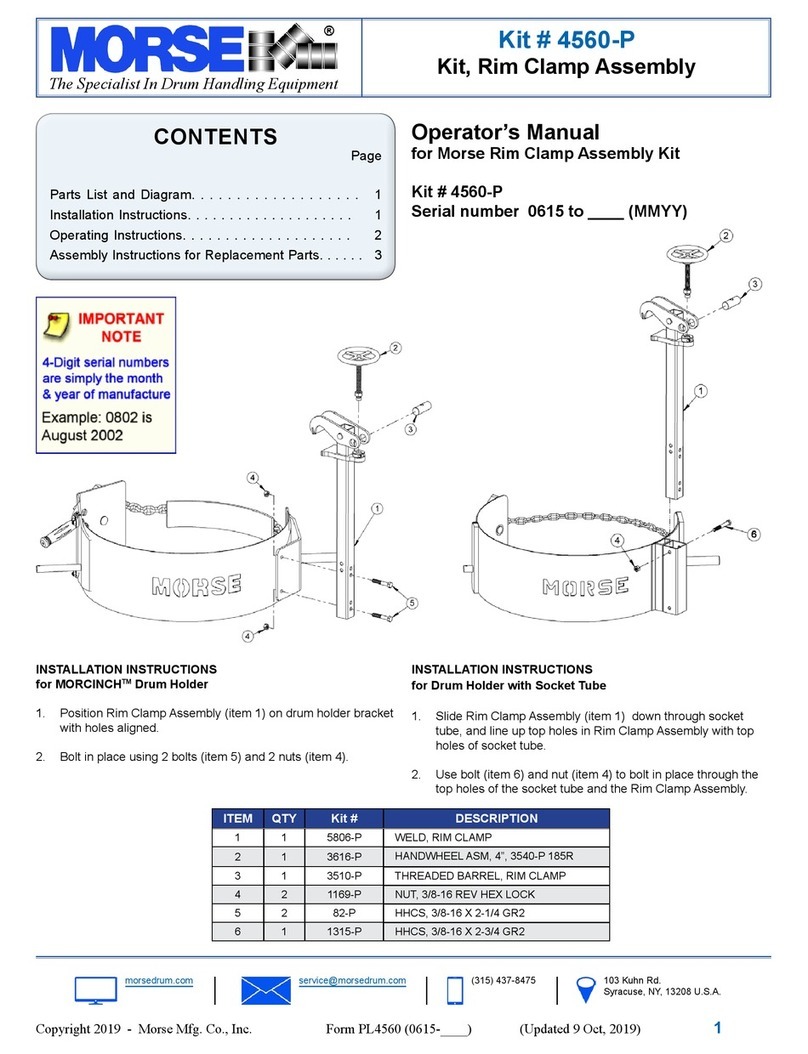

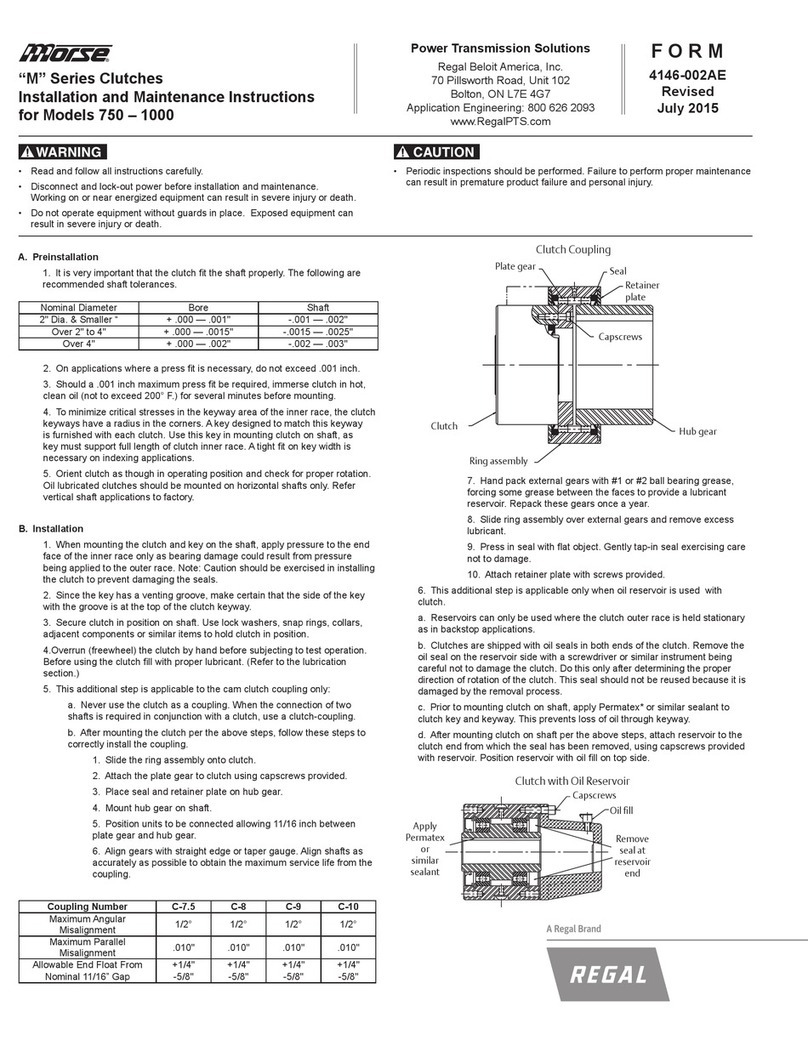

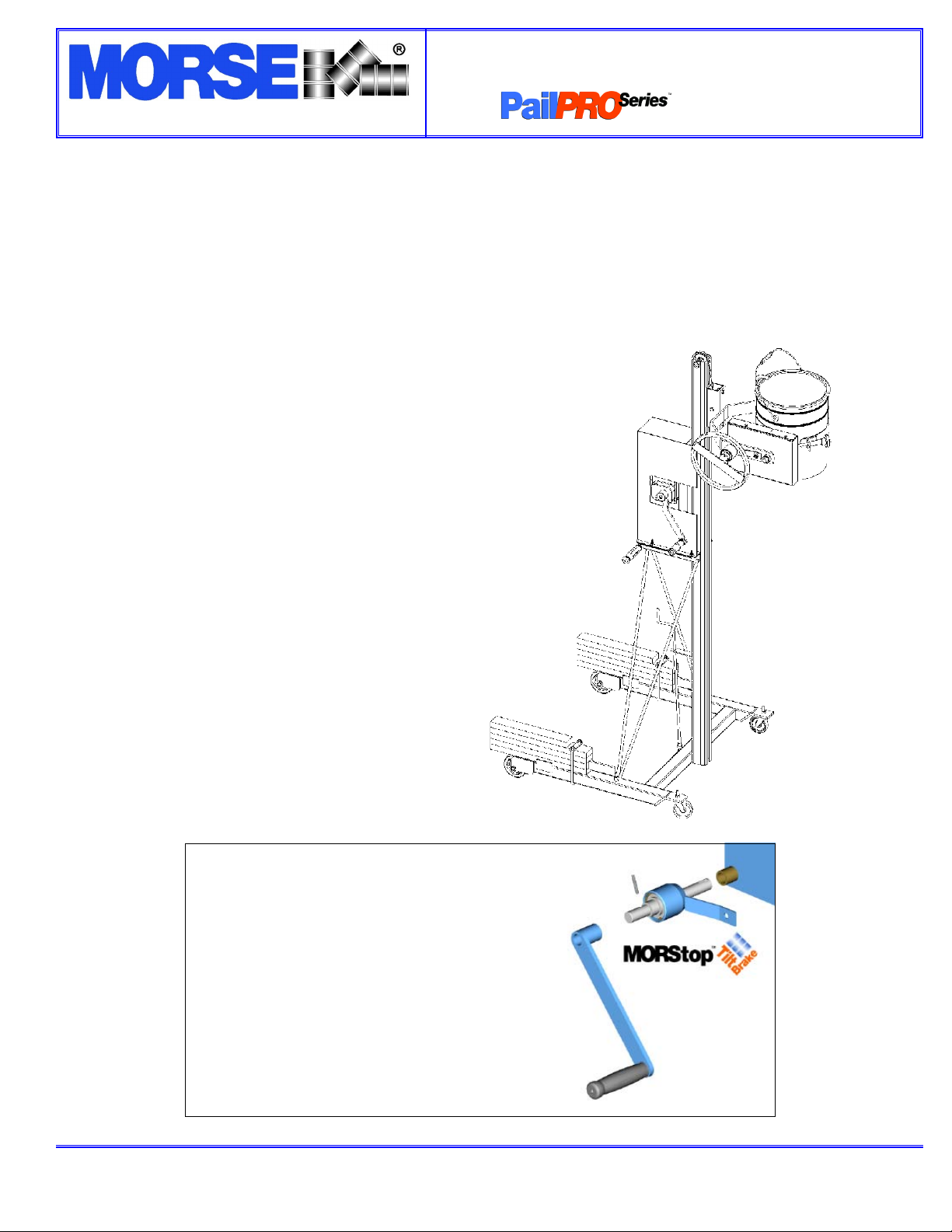

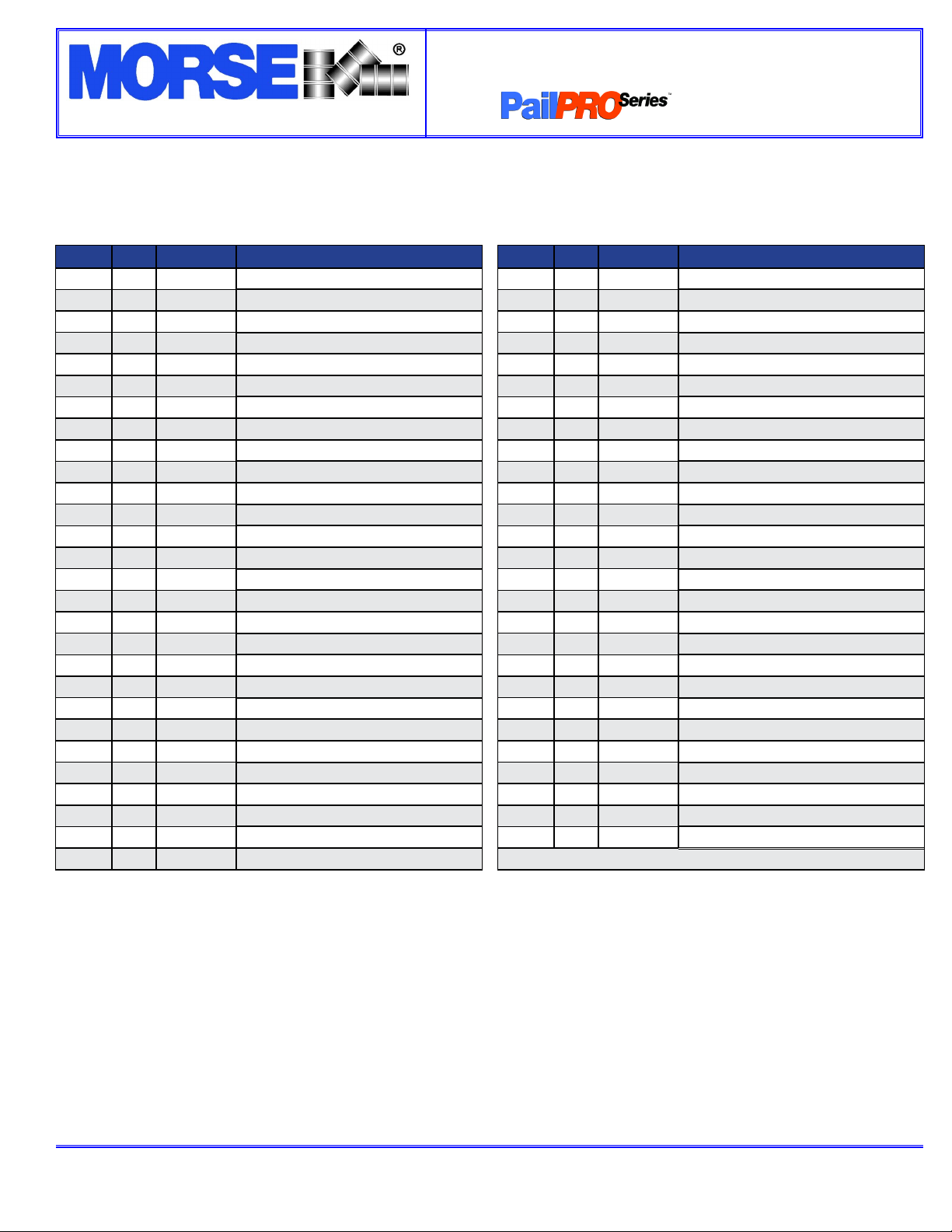

Parts List for Morse 5-Gallon Pail Handler Model 83

Serial Number 1105 to 0311 (MMYY)

The Specialist In Drum Handling Equipment

MODEL 83

Pail Handler

COPYRIGHT 2007 MORSE MFG. CO., INC. Form PL 83 (1105 - 0311) (Updated 10-2007) Page 7

ITEM # QTY. PART # DESCRIPTION

1 2 3829-P GUARD WELD, 83

2 9 1169-P NUT, 3/8-16 REV HEX LOCK

3 5 1166-P WASHER, 3/8 USS 1” OD

4 1 3797-P WINCH, 83

5 1 4365-P WIRE CABLE CPT, 1/8”, 83

6 4 1035-P COLLAR, 1/2”

8 2 3803-P SHAFT, PULLEY, 83

9 1 3798-P TOP SHEAVE, 3” POLY, 83 PP

10 1 3911-P MID SHEAVE, 1-1/2 STEEL, 83

11 1 4355-P MAST WELD, 83

12 1 4329-P CARRIAGE ASM, 83

13 5 1315-P HHCS, 3/8-16 X 2-3/4 GR2

14 2 3921-P NUT, ACORN, 3/8-16

15 2 3885-P WHEEL, 4 X 1-1/2, 83

16 2 3789-P CASTER, STEM, 3” SWIVEL, 83

17 1 3790-P BASE WELD, 83

18 4 35-P 5/16 - 18 X 1 HHCS GR 2

19 2 136-P HANDLE GRIP, 7/8” X 4-3/4”

20 1 4381-P HHCS, 3/8-16 X 3-1/2 GR5

21 1 4358-P HANDLE WELD, 83

22 1 8353-P PAD FLOOR LOCK DRILLED, 83

23 1 3775W-P ANGLE, FLOOR LOCK WELD, 83

25 1 8351W-P CRANK WELD, FLOOR LOCK, 83

26 1 1675-P ROLL PIN, 1/8 X 7/8

27 4 3920-P NUT, LOCK, 5/16-18 NYLON

28 4 4068-P ROLLER, GORBEL, 83

29 4 4071-P SNAP RING, .669 ID, 83

30 2 149-P NUT, FIN, 3/8-16 HEX

ITEM # QTY. PART # DESCRIPTION

31 2 1474-P WASHER, 3/8 SPLIT LOCK

32 3 1572-P HHCS, 3/8-16 X 1 GR2

33 2 1641-P HHCS, 1/4-20 X 1 GR2

34 1 4163B-P COVER, GEARS, INSIDE BACK 83

35 1 4163C-P COVER, GEARS, INSIDE FRONT 83

36 1 3794-P BACK BAND WELD, 83

37 4 1297-P NUT, LOCK, 1/4-20 REV HEX

38 1 4161-P PLATE, IDLER, BOLT ON, 83

39 2 64-P ROLL PIN, 3/16 X 1-1/4

40 1 55-P WASHER, 3/4 SAE FL 1-1/2 OD

41 2 3804-P SHCS, 1/4-20 X 3-1/4

43 1 3714W-P KNOB WELD, CLAMP SCREW 83, 7-X

44 1 3795-P FRONT BAND WELD, 83

45 1 4221-P CLAMP SCREW WELD, 83

46 1 3796-P SADDLE ASM, 83

47 1 4163A-P COVER, GEARS, OUTSIDE, 83

48 4 193-P SCREW, TEK, 12-14 X 3/4, 3 PT

49 1 2537-P CHAIN, ROLLER, #35 72 PITCH

50 1 7-P BEARING, 3/4” ID X 1-1/2”

51 1 15-P COLLAR, 3/4” ID

52 1 4385-P HANDWHEEL, 10” 3/4” BORE, 83

53 1 3901-P MORStop TILT BRAKE

54 1 19-P BEARING, 3/4” ID X 2-1/2”

55 1 4082-P CARRIAGE WELD, BOLT ON, 83

56 1 735-P KEY, WOODRUFF, SIZE 9, ASA606

57 1 11-P SPROCKET, #35 12T, 3/4” BORE

58 1 4083-P TROLLEY WELD, 83

* Recommended spare parts