1

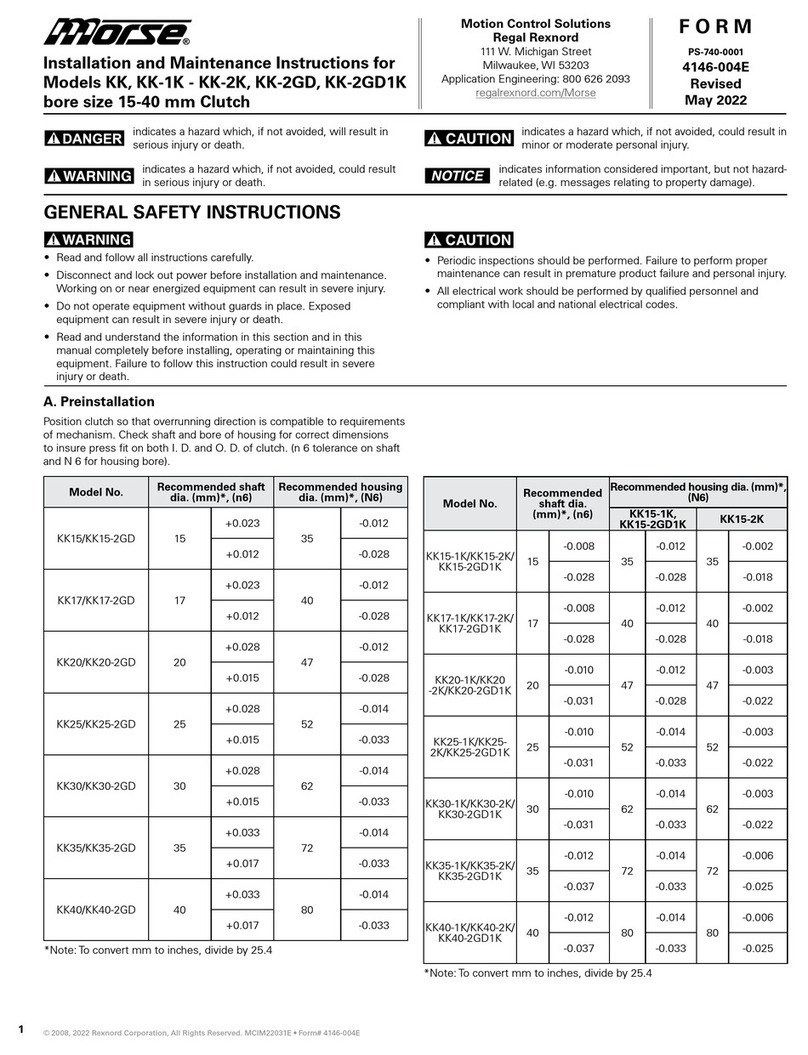

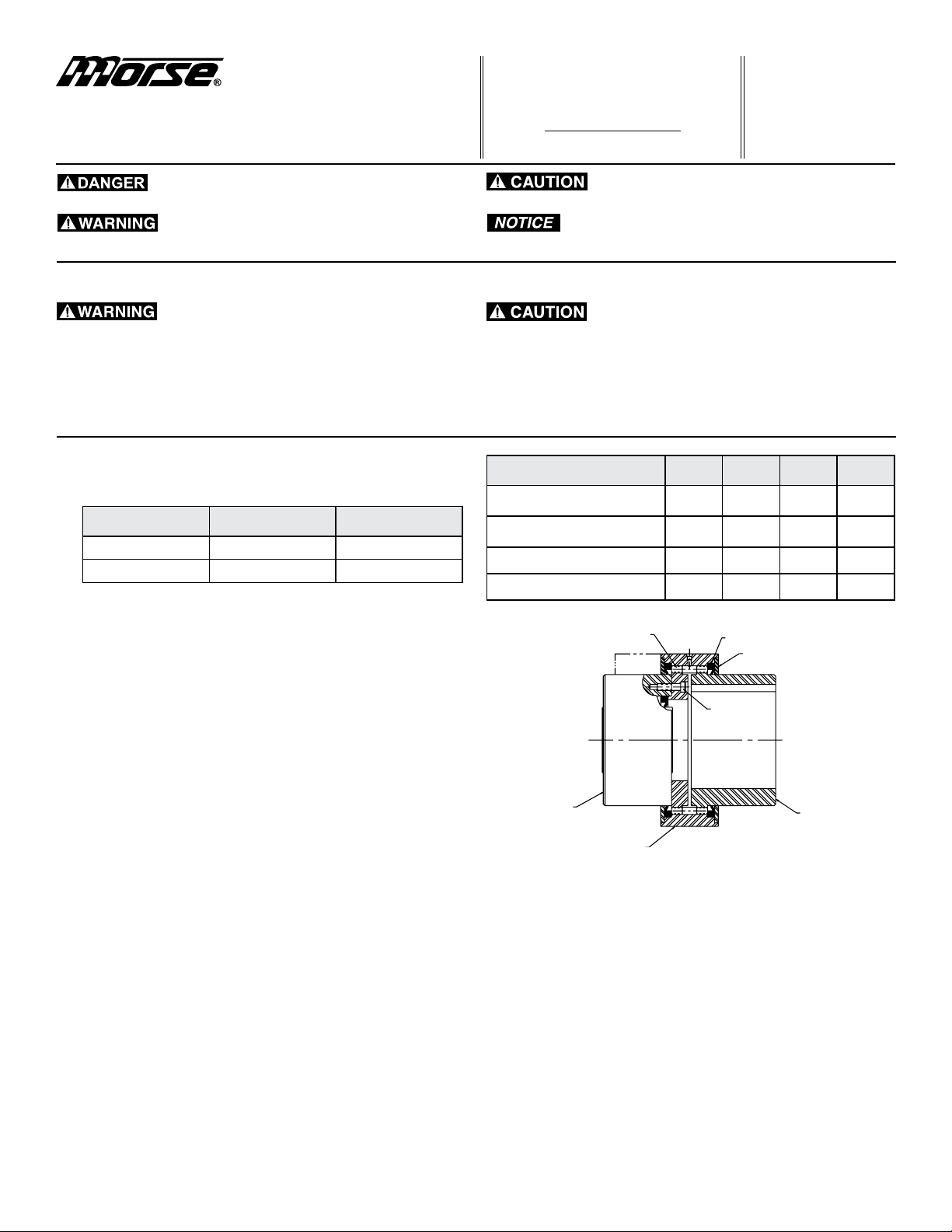

A. Preinstallation

1. It is very important that the clutch fit the shaft properly. The following are

recommended shaft tolerances.

Nominal

Diameter Bore Shaft

Over 2" to 4" + .0000 / -.0015" -.0015 / -.0025"

4" to 6” + .0000 / -.0020" -.0020 / -.0030"

2. On applications where a press fit is necessary, do not exceed .001 inch.

3. Should a .001 inch maximum press fit be required, immerse clutch in hot, clean

oil (not to exceed 200° F.) for several minutes before mounting.

4. To minimize critical stresses in the keyway area of the inner race, the clutch

keyways have a radius in the corners. A key designed to match this keyway

is furnished with each clutch. Use this key in mounting clutch on shaft, as

key must support full length of clutch inner race. A tight fit on key width is

necessary on indexing applications.

5. Orient clutch as though in operating position and check for proper rotation. Oil

lubricated clutches should be mounted on horizontal shafts only. Refer vertical

shaft applications to factory.

B. Installation

1. When mounting the clutch and key on the shaft, apply pressure to the end

face of the inner race only as bearing damage could result from pressure being

applied to the outer race. Note: Caution should be exercised in installing the

clutch to prevent damaging the seals.

2. Since the key has a venting groove, make certain that the side of the key with

the groove is at the top of the clutch keyway.

3. Secure clutch in position on shaft. Use lock washers, snap rings, collars,

adjacent components or similar items to hold clutch in position.

4. Overrun (freewheel) the clutch by hand before subjecting to test

operation. Before using the clutch fill with proper lubricant. (Refer to the

lubrication section.)

5. This additional step is applicable to the cam clutch coupling only:

a. Never use the clutch as a coupling. When the connection of two shafts is

required in conjunction with a clutch, use a clutch-coupling.

b. After mounting the clutch per the above steps, follow these steps to

correctly install the coupling.

1. Slide the ring assembly onto clutch.

2. Attach the plate gear to clutch using capscrews provided.

3. Place seal and retainer plate on hub gear.

4. Mount hub gear on shaft.

5. Position units to be connected allowing 11/16 inch between plate

gear and hub gear.

6. Align gears with straight edge or taper gauge. Align shafts as

accurately as possible to obtain the maximum service life from

the coupling.

F O R M

“M” Series Clutches

Installation and Maintenance Instructions

for Models 750 – 1000

PN 654027, PS-740-0001

4146-002AE

Revised

May 2022

• Perform periodic inspections. Equipment may fail prematurely

and could become unsafe if not properly inspected and

maintained. Failure to follow this instruction could result in mild

or moderate personal injury.

• Read and follow all instructions carefully.

• Disconnect and lock-out power before installation and

maintenance. Working on or near energized equipment can

result in severe injury or death.

• Do not operate equipment without guards in place. Exposed

equipment can result in severe injury or death.

GENERAL SAFETY INSTRUCTIONS

indicates a hazard which, if not avoided, will result

in serious injury or death.

indicates a hazard which, if not avoided, could

result in minor or moderate personal injury.

indicates a hazard which, if not avoided, could

result in serious injury or death.

indicates information considered important, but

not hazard-related (e.g. messages relating to property damage).

Motion Control Solutions

Regal Rexnord

111 W. Michigan Street

Milwaukee, WI 53203

regalrexnord.com/Morse

© 2009, 2022 Regal Rexnord Corporation, All Rights Reserved. MCIM22029E • Form# 4146-002AE

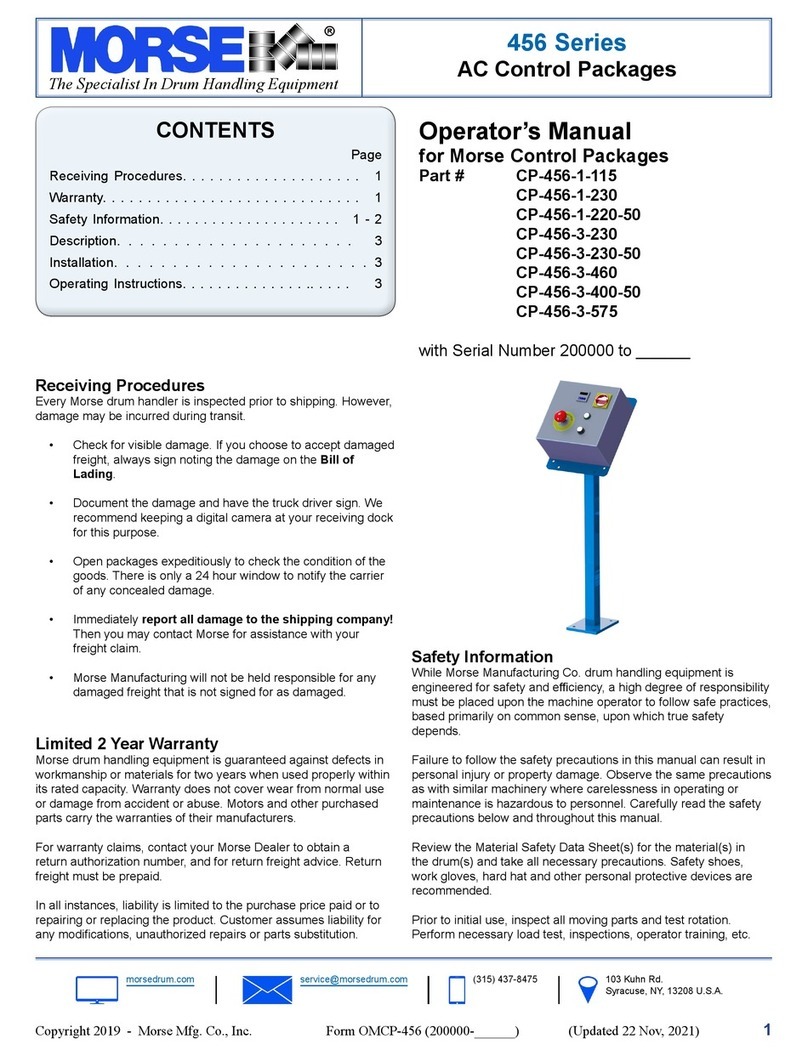

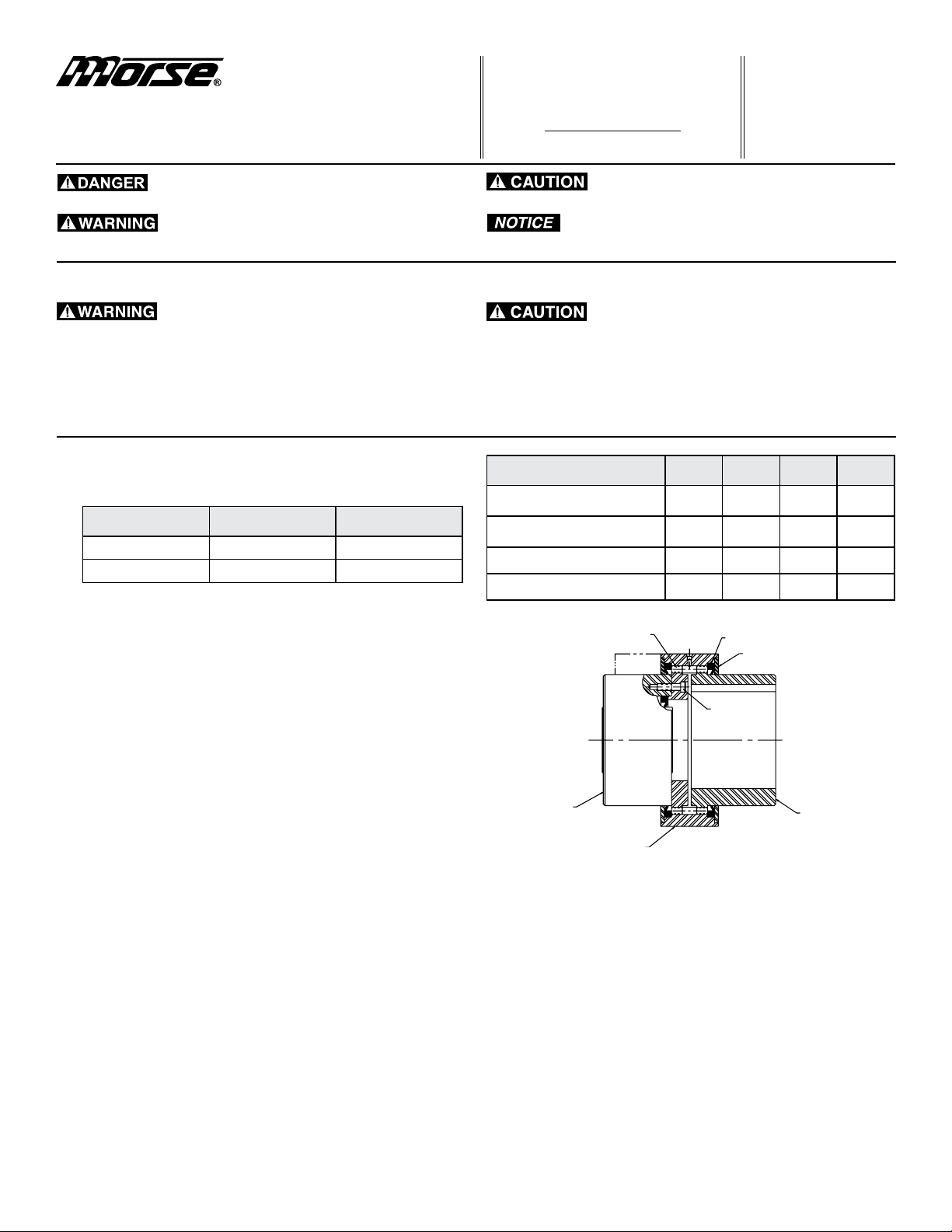

Coupling Number C-7.5 C-8 C-9 C-10

Maximum Angular

Misalignment 1/2° 1/2° 1/2° 1/2°

Maximum Parallel

Misalignment .010" .010" .010" .010"

Allowable End Float From +1/4" +1/4" +1/4" +1/4"

Nominal 11/16” Gap -5/8" -5/8" -5/8" -5/8"

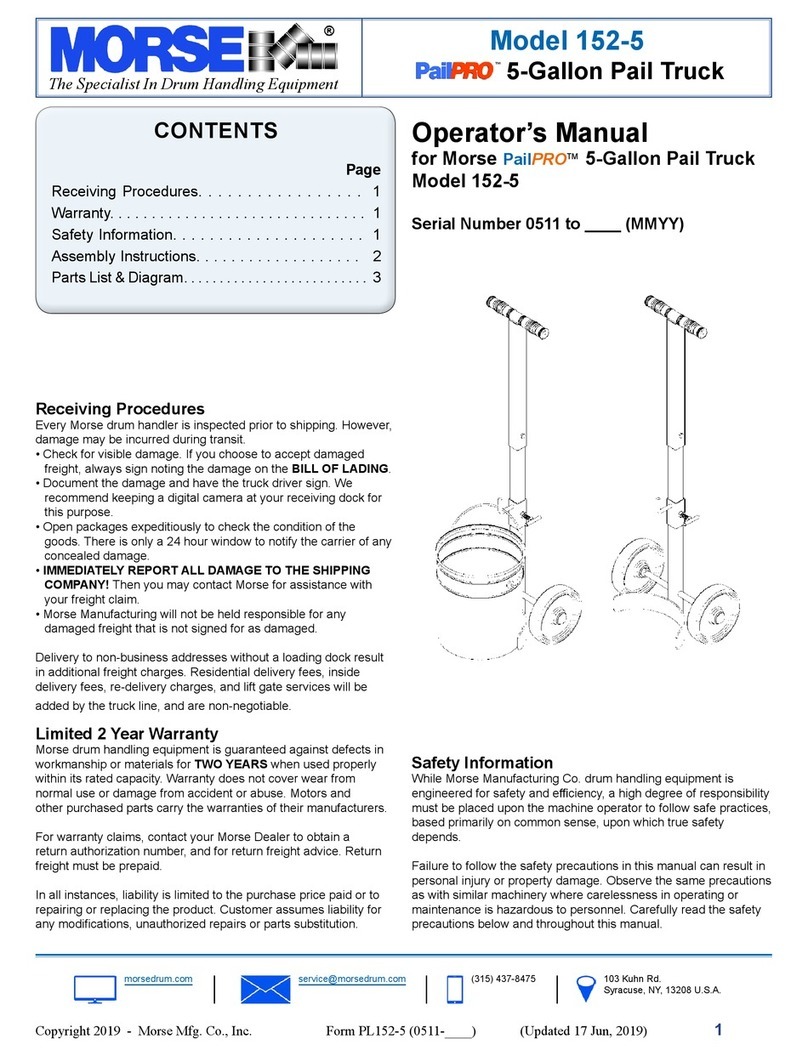

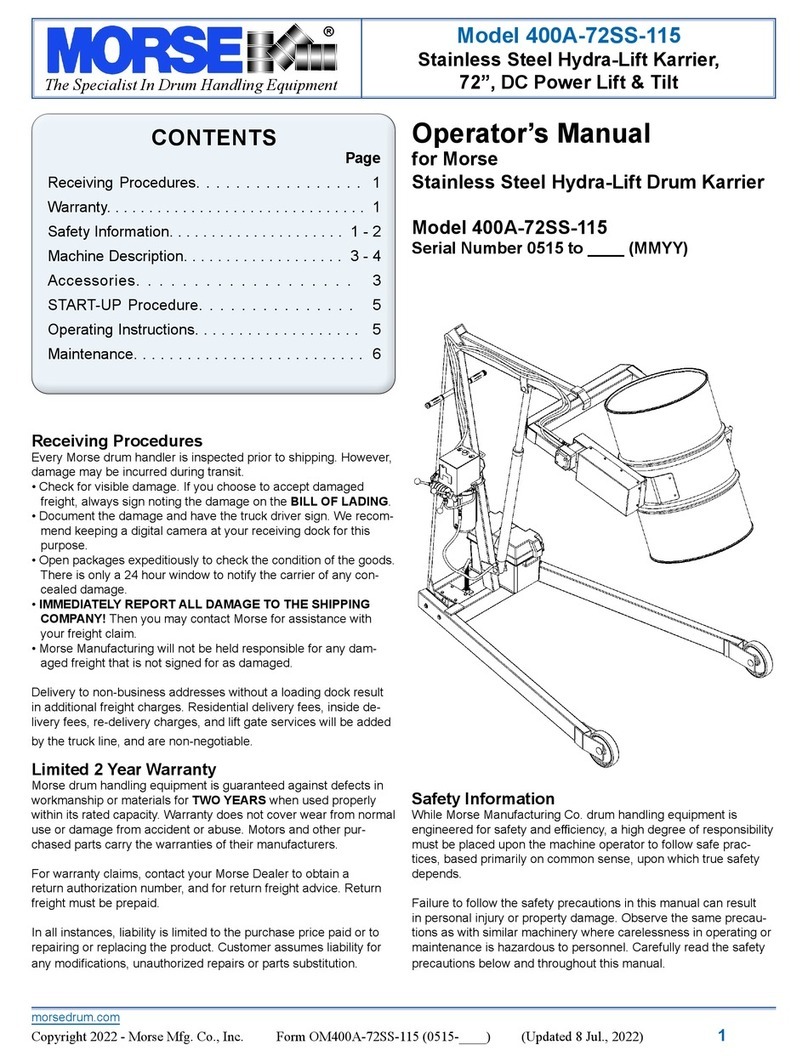

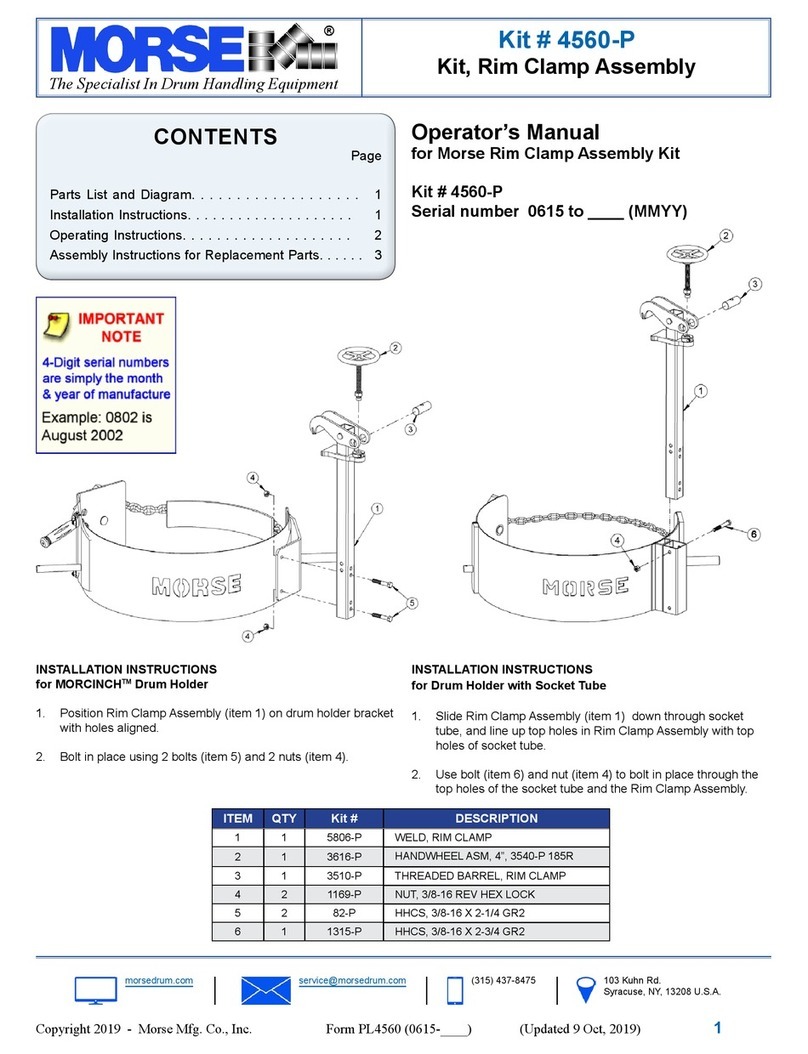

Clutch Coupling

Seal

Retainer

plate

Hub gear

Ring assembly

Clutch

Capscrews

Plate gear

7. Hand pack external gears with #1 or #2 ball bearing grease, forcing

some grease between the faces to provide a lubricant reservoir.

Repack these gears once a year.

8. Slide ring assembly over external gears and remove excess

lubricant.

9. Press in seal with flat object. Gently tap-in seal exercising care not

to damage.

10. Attach retainer plate with screws provided.

6. This additional step is applicable only when oil reservoir is used with clutch.

a. Reservoirs can only be used where the clutch outer race is held

stationary as in backstop applications.

b. Clutches are shipped with oil seals in both ends of the clutch. Remove

the oil seal on the reservoir side with a screwdriver or similar instrument

being careful not to damage the clutch. Do this only after determining

the proper direction of rotation of the clutch. This seal should not be

reused because it is damaged by the removal process.

c. Prior to mounting clutch on shaft, apply Permatex®* or similar sealant to

clutch key and keyway. This prevents loss of oil through keyway.

* Permatex is believed to be the trademark and/or trade names of Illinois Tool Works, Inc. and is not

owned or controlled by Regal Rexnord Corporation.