The Specialist In Drum Handling Equipment

456 Series

Hydra-Lift Drum Rollers

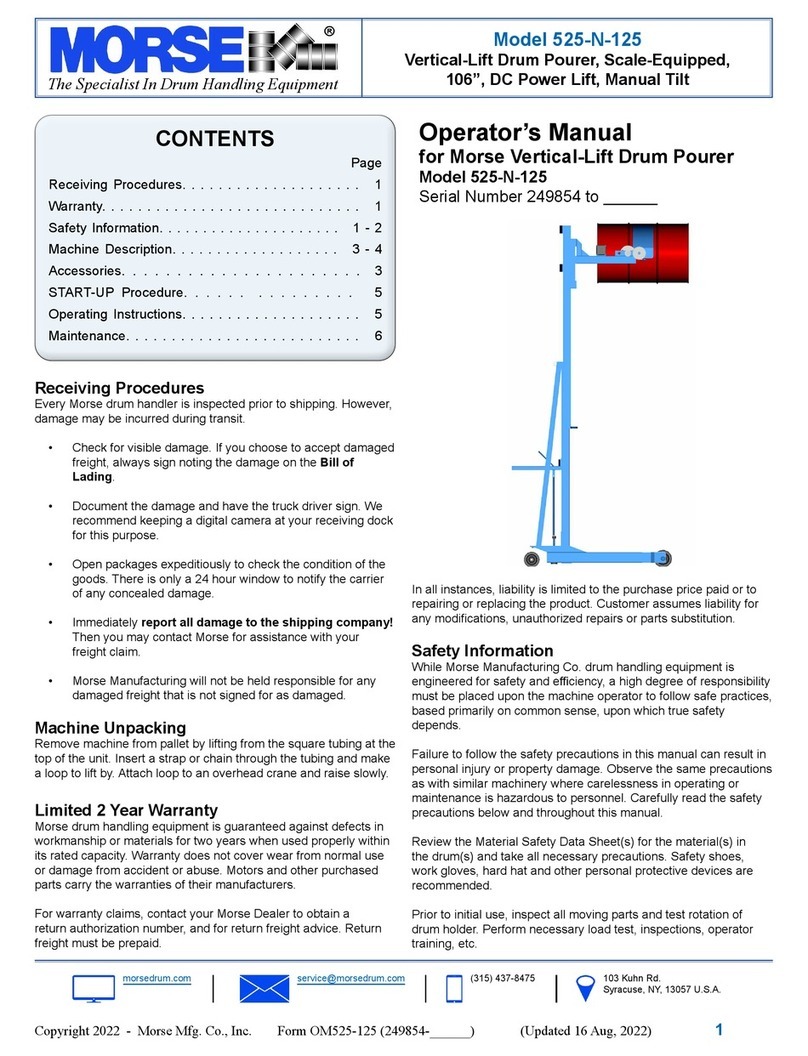

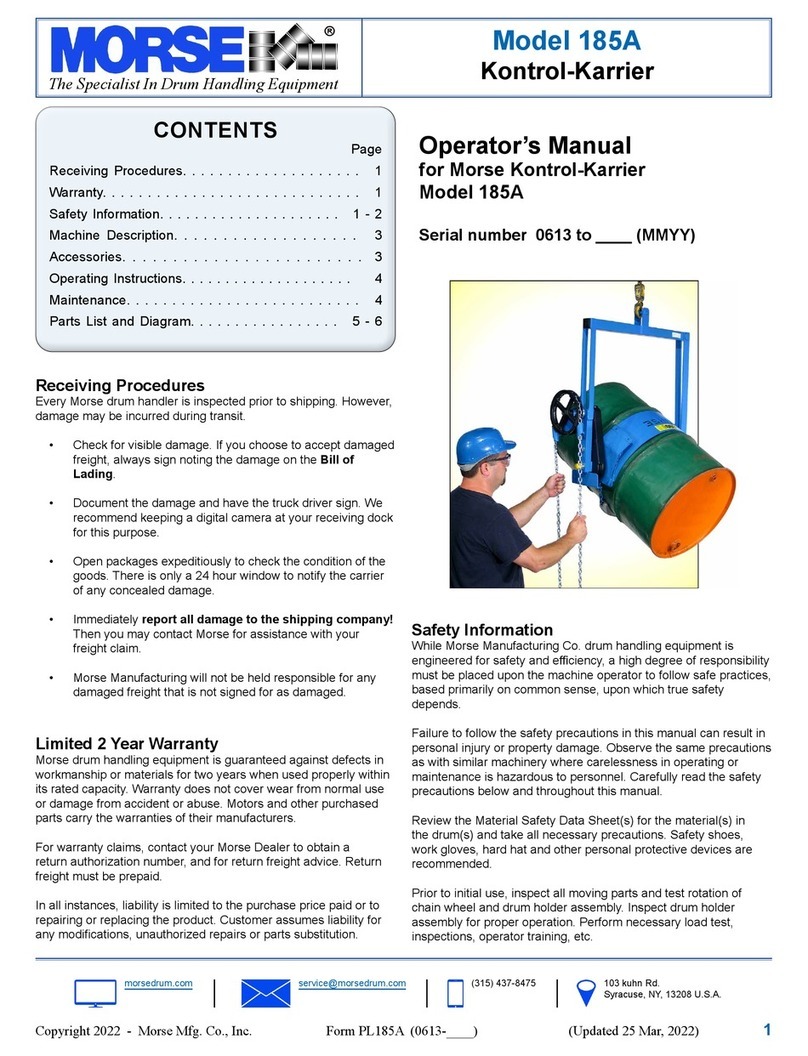

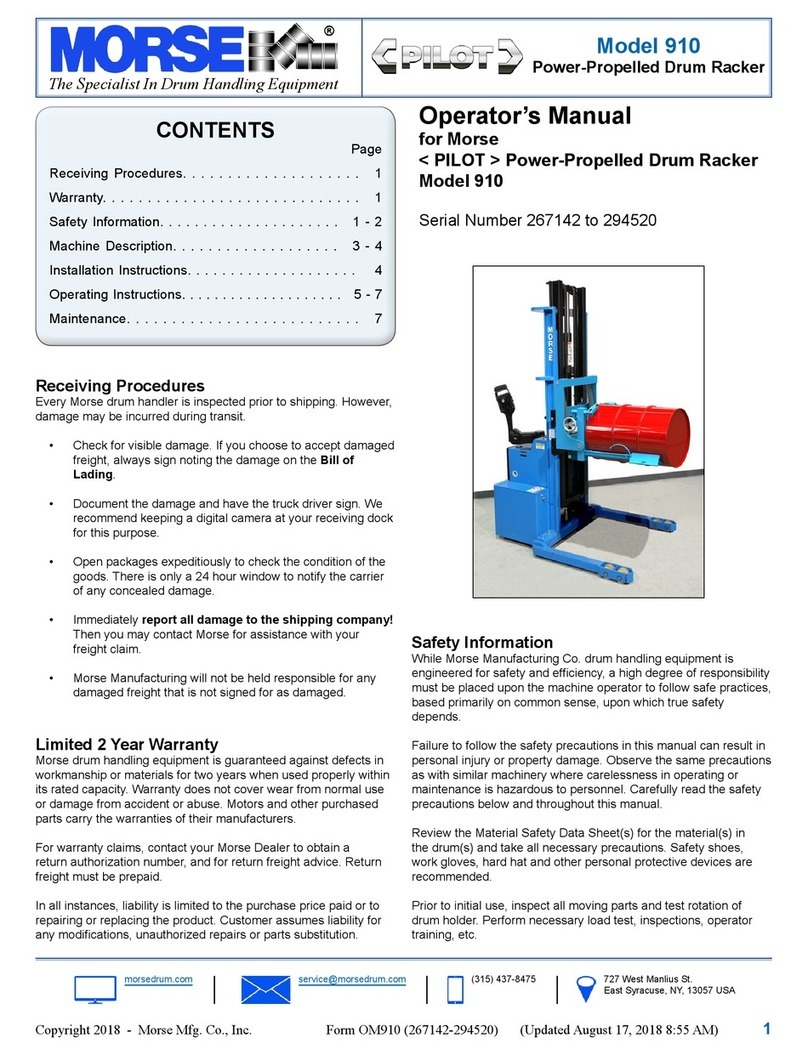

Operator’s Manual for Morse 456 Series Hydra-Lift Drum Rollers

Serial Number 266289 to 283647

morsedrum.com

Copyright 2016 - Morse Mfg. Co., Inc. Form PL456 (266289-283647) (Updated March 19, 2018 4:21 PM) 3

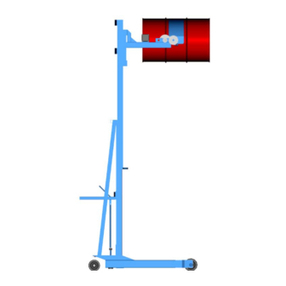

Machine Description

The Morse 456 Series Hydra-Lift Drum Rollers are designed to

receivean uprightdrumatoorlevel, hydraulicallytilt drumto

horizontal, and rotate the drum on its side between 5 and 20

RPM (4 to 16 RPM with 50Hz models). It is designed to rotate a

steel drum 6” to 28” in diameter, and up to 40” tall. The maximum

liquid capacity is 1000 Lb. Capacity is derated to 400 Lb. for a

dry load.

See VIDEO online

Options

A 1 to 5 gallon can or pail can be rotated with the optional•

Idler Attachment (part # 1-5-1) installed.

A 55-gallon plastic drum can be rotated with the correct•

POLY option installed.

Order Option POLY-456 factory installed on your new•

456 Series Drum Roller.

Order Option POLY-456FI for feld installation of POLY•

Kit on your existing 456 Series Drum Roller.

Guard Enclosure Kit - Install all Morse Rotators in accordance•

with OSHA requirements for enclosure and safety interlock,

etc. so the rotator automatically turns off when enclosure

door is opened. One way to accomplish this is with a Morse Guard Enclosure with safety interlock.

Controls

There are two powered functions for the operator to control. Each function is controlled separately by levers mounted on the control

station.

The “TILT” function, for vertical positioning of the drum holder. The lever on the right side is the “TILT” control valve. Raising the lever1.

will tilt the drum to vertical. Lowering the lever will tilt the drum to horizontal.

The “ROLL” function, or the rotation of the drum holder. The lever on the left side is the “ROLL” control valve. Raising this lever causes2.

the drum to rotate. Lowering the lever away from the operator will stop the drum from rotating. The rotation speed can be varied with the

metering valve (item 13 on page 8). Turn the valve clockwise to increase speed up to a nominal 20 RPM, counterclockwise to decrease

speed down to a nominal 5 RPM. RPM is based on a 22.5” diameter 55-gallon steel drum and a 60Hz 1725 RPM motor.

Installation Instuctions

Hydra-LiftRotatorsareshippedlledwith1gallonofhydraulicuid(Dexron3or

equivalent). Replace the red shipping plug from the hydraulic reservoir with the

supplied black breather, and install hydraulic levers BEFORE operation.

The base has four 1/2” (1.27 cm) diameter holes spaced 20-3/8” wide x 62-5/8”

long (51.75 cm wide x 159.07 cm long). Morse recommends the rotator be secured

totheoorusing3/8”x3”(.95cmx7.6cm)lagbolts(notincluded).

Install all Morse Rotators in accordance with OSHA requirements for enclosure and safety interlock, etc. Drum rotator must automatically

turn off when enclosure door is opened.

Control Station - Making Connections:

Fortheairmotorpoweredrotator,alter,regulator,lubricatorismountedonthecontrolstation.Ashutoffballvalveisinstalledonthe•

inlet of the regulator. The air connection should be made at the inlet of this valve.

Ensure that the supply air lines are of sufcient size to provide proper air volume. The air motor requires 40 scfm, and 40 psi of•

compressed air. (The proper air pressure will depend on the weight of the drum.)

For AC motor powered rotator, the main power must be wired into the control box.•

Models ordered with non-explosion proof motor (i.e. 456-1-115) have the control box wired to the motor.•

Models ordered with explosion proof motor (i.e. 456-E1-115) have no wiring from the nema 7/9 control box to the motor. Please consult•

an electrician to complete the wiring. The motor should turn clockwise when viewed from the fan end. Jog the motor to determine

properrotation.Intheeventuiddoesnotow,checkmotorwiringdiagramforclockwiserotation.

Model # Motor Style Phase Volts Hz Amp Draw Drum RPM

456-1-115 TEFC 1 115 60 12.8 5 to 20

456-1-230 TEFC 1 230 60 6.4 5 to 20

456-3-230 TEFC 3 230 60 3.4 5 to 20

456-3-460 TEFC 3 460 60 1.7 5 to 20

456-3-575 TEFC 3 575 60 1.5 5 to 20

456-A Air Motor Air Motor Technical Info 5 to 20

456-E1-115 Explosion Proof * 1 115 60 13 5 to 20

456-E1-230 Explosion Proof * 1 230 60 6.5 5 to 20

456-E3-230 Explosion Proof * 3 230 60 3.6 5 to 20

456-E3-460 Explosion Proof * 3 460 60 1.8 5 to 20

456-1-220-50 TEFC 1 220 50 6.2 4 to 16

456-3-220-50 TEFC 3 220 50 3.1 4 to 16

456-3-380-50 TEFC 3 380 50 2.1 4 to 16

456-3-440-50 TEFC 3 440 50 1.75 4 to 16

456-E1-220-50 Explosion Proof * 1 220 50 6.2 4 to 16

456-E3-220-50 Explosion Proof * 3 220 50 3.45 4 to 16

456-E3-380-50 Explosion Proof * 3 380 50 2.1 4 to 16

456-E3-440-50 Explosion Proof * 3 440 50 1.8 4 to 16

* Explosion Proof Motors are rated for Class I Group D, and Class II Groups F and G.