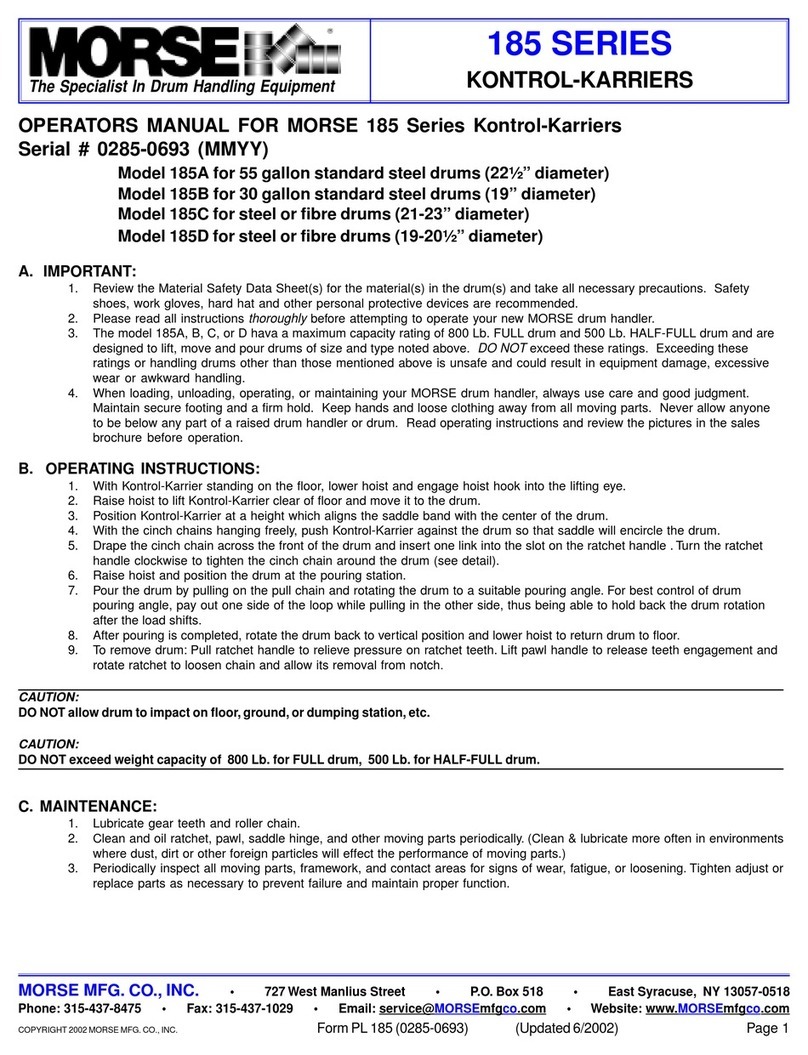

PARTS LIST FOR MORSE 185HD Series Heavy-Duty Kontrol-Karriers

Serial # 0000 to 0285 (MMYY)

Website: www.MORSEmfgco.com

COPYRIGHT2002MORSEMFG.CO.,INC. FormPL185HD (0000-0285) (Updated6/2002) Page 2

185HD SERIES

HEAVY-DUTYKONTROL-KARRIERS

The Specialist In Drum Handling Equipment

MORSE MODEL 185A-HD SERIES KONTROL-KARRIER S/N 0000-0285

ITEM

NUMBER

MODEL LETTER

SUFFIX

see note #1 QTY P/N DESCRIPTION

1 1 1-P CHAIN WHEEL #1-1/2 W/GUIDE

2 1 2-185-P PULL CHAIN,1/0,12'LENGTH

3 1 3-P TRIANGLE & SHAFTW/ BOLTS

4 1 4-P SPACER, CHAIN WHEEL, PRE 19-P

5 2 6-P BEARING(DF1013-4)

6 1 11-P SPROCKET,#35 12T,3/4"BORE

7 1 12-P CHAIN,ROLLER,#35 W/MLINK

8 1 13-P SPROCKET #35 36T, 3/4" BORE

9 1 14-P GEAR, PINION, 7 TOOTH

10 2 735-P KEY, WOODRUFF, SIZE 9, ASA606

11 1 27-P SPUR GEAR W/1"SHAFT, HD TYPE

12 2 736-P KEY, WOODRUFF, SIZE 15, ASA808

13 1 26-P SPUR GEAR SPACER

14 1 34-P DRIVE SHAFTSPACER HD PRE85

15 2 8-P BEARING,SH326, PRE 18-P

16 3 33-P ALEMITE GREASE FIT

17 2 15-P COLLAR,3/4"ID

18 1 30-P SPROCKET #40D 16T,1" BORE

19 1 31-P CHAIN,ROLLER,#40D W/M. LINK

20 1 32-P SPROCKET #40D 32T,1" BORE

21 1 45-P ** OVERHEAD, 185HD,PRE 0285

22 1 41-P ** HINGE PIN WITH NUT

23 1 40-P ** IDLER ARM

24 A 1 103A-P SADDLECPT, 185A-HD

24 B 1 103B-P SADDLECPT, 185B-HD

24 C 1 103C-P SADDLE CPT,185C-HD

24 D 1 103D-P SADDLE CPT,185D-HD

25 A 1 132A-P DRUMBAND ONLY185A-HD

25 B 1 132B-P DRUMBAND ONLY185B-HD

25 C 1 132C-P DRUMBAND ONLY185C-HD

25 D 1 132D-P DRUMBAND ONLY185D-HD

26 2 157-P HINGE PIN & NUTS,3/8

27 1 150-P CHAIN HINGE PLT, 285 TYPE

28 1 155-P 3/8 - 16 X2-1/2 HHCS GR 2

29 A,B 1 180-P CHAIN,CINCH,3/16 ALLOY33 LK

30 C,D 1 E14 FIBRE DRUMSTRAP 14"

31 1 159-P RATCHETHINGE PLATE ONLY, 3/8"

32 1 169-P PAWL SPRING

33 1 170-P 3/8"DIAX5/8"SHOULDER SCREW

34 1 168-P PAWL, WITH DRILLED HOLE

35 1 165-P RATCHET,MALLEABLE,SADDLE

36 1 166-P SNAP RING, EXTERNAL,5SSC-P 82

37 1 159-PC RATCHETHINGE PLATE CPT,3/8"

38 1 165KIT-P KIT,RATCHET CHAIN TIGHTENER

** Items 21, 22 and 23 have been discontinued and are no longer available.

Please call Morse for substituted parts.

Note #1: If no letter is shown, the part is for Models 185A-HD, 185B-HD, 185C-HD, or 185D-HD

If a letter is shown, the part is for the model with that letter suffix only.

Note #2: "SADDLE COMPLETE" includes the drum band and appropriate attached moving parts, 26-36.