The Specialist In Drum Handling Equipment

MODEL 80i

Mobile-Karrier

Operator’s Manual for Model 80i Morse Mobile-Karrier

Serial Number 1114 to 0515 (MMYY)

morsedrum.com

Copyright 2015 - Morse Mfg. Co., Inc. Form PL80i (1114-0515) (Updated April 29, 2015 1:02 PM) 4

Operating Instructions

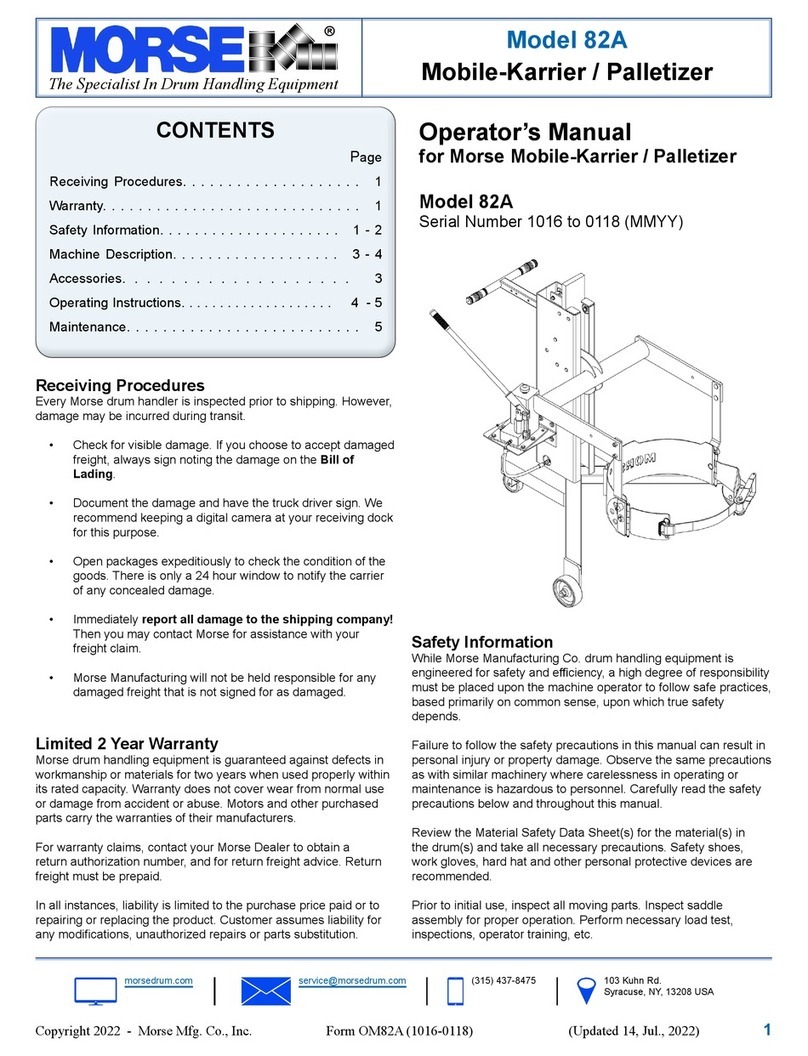

Roll the assembled Mobile-Karrier to the drum (assembly1.

instructions are on page 4).

Grip the push-handle, squeeze both release rods and raise the2.

handle to a position straight up. This lowers the saddle to reach

the middle of the drum. The cinch chain can be hung on the

chainpinontopofleftstanchiontokeepitofftheoor.

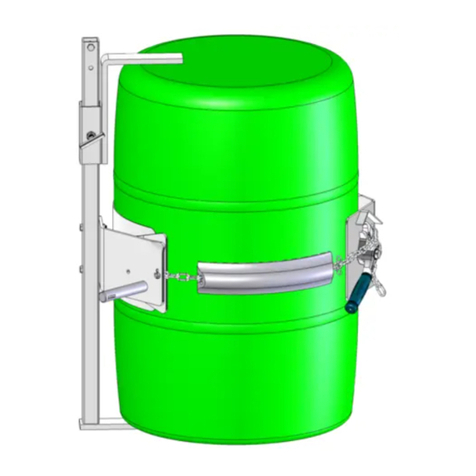

Roll the Mobile-Karrier forward and push the saddle so that it3.

slips around the drum near the mid-point of the drum.

Secure the drum: Drape the cinch chain across the face of the4.

drum and engage a link into the notch in the hub of the ratchet

(shown below right). Pull up on ratchet handle to tighten the

chain. If ratchet turns to the extent that the pawl is beyond the

last ratchet tooth and the chain is not tight, back up and try

putting the next link in the notch. The chain should tighten as

the ratchet turns and be held tight by the teeth of the ratchet

and pawl. Firm hand pressure on the ratchet handle should

tensionthechainsufcientlytosecurethedrum.DONOTuse

mechanical aids such as a pipe to extend ratchet handle for

extra leverage.

Pull down the push-handle to raise the drum. The Mobile-5.

Karrier will hold up the drum and may be rolled away carrying

the drum.

Either one of the two spring loaded plunger tilt locks may be6.

locked to hold the drum upright. Unlocking both will permit the

drum to be tilted. Either one may be locked to hold the drum

in the tilted position. It is not necessary to lock both tilt locks.

Beforeunlockingthetiltlockitisrecommendedthatyousteady

the drum and be prepared to resist its tendency to tilt toward

its heavy end.

Beforeunloadingthedrum,releasethetiltlocksandreturnthe7.

drum to upright.

Itisnecessarytohavearm,twohandholdtolowerthepush-8.

handle and squeeze the release rods. With both release rods

squeezed, the handle will unlock and allow the weight of the

drum to make the handle tend to rise.Apply sufcient force

to allow the handle to rise slowly to control the descent of the

drum.

LEVERAGEAND HEIGHTADJUSTMENTS: The Mobile-Karrier9.

will hold a vertical drum and raise it as high as 11”. With the drum

heldhorizontally,therecanbeasmuchas17”oorclearance.

There are extra holes in the handle plates and links to provide

adjustment for various heights and drum weights. The greatest

leverage,withtheleastliftheightisobtainedwhenusingthehandle

holes nearest the handle pivot. This position is recommended

for ease of use when extra oor clearance is not necessary.

Maintenance

Periodicinspectionforthegeneralconditionofstructuralandmechanicalcomponentsisimperativeforsafeandefcientoperation.•

Periodically inspect all moving parts, framework, and contact areas for signs of wear, fatigue, or loosening. Tighten, adjust, or•

replace parts as necessary to prevent failure and maintain proper function.

Grease wheel bearings periodically. Oil or grease all moving parts including: Tilt locks, fulcrum shafts, links, 1/2” carriage bolts, and•

the ratchet and pawl.

Worn or damaged parts must be properly replaced with the correct, genuine Morse parts.•

Tighten all nuts and bolts periodically, except the four 1/2” carriage bolts (assembly steps 1, 2 and 3) which should be just loose•

enough to permit a hinging motion of the links and handle.