AX34209a_e.doc / Mrz-16 Page 3 / 38

Table of Contents

1. Introduction..........................................................................................................................................4

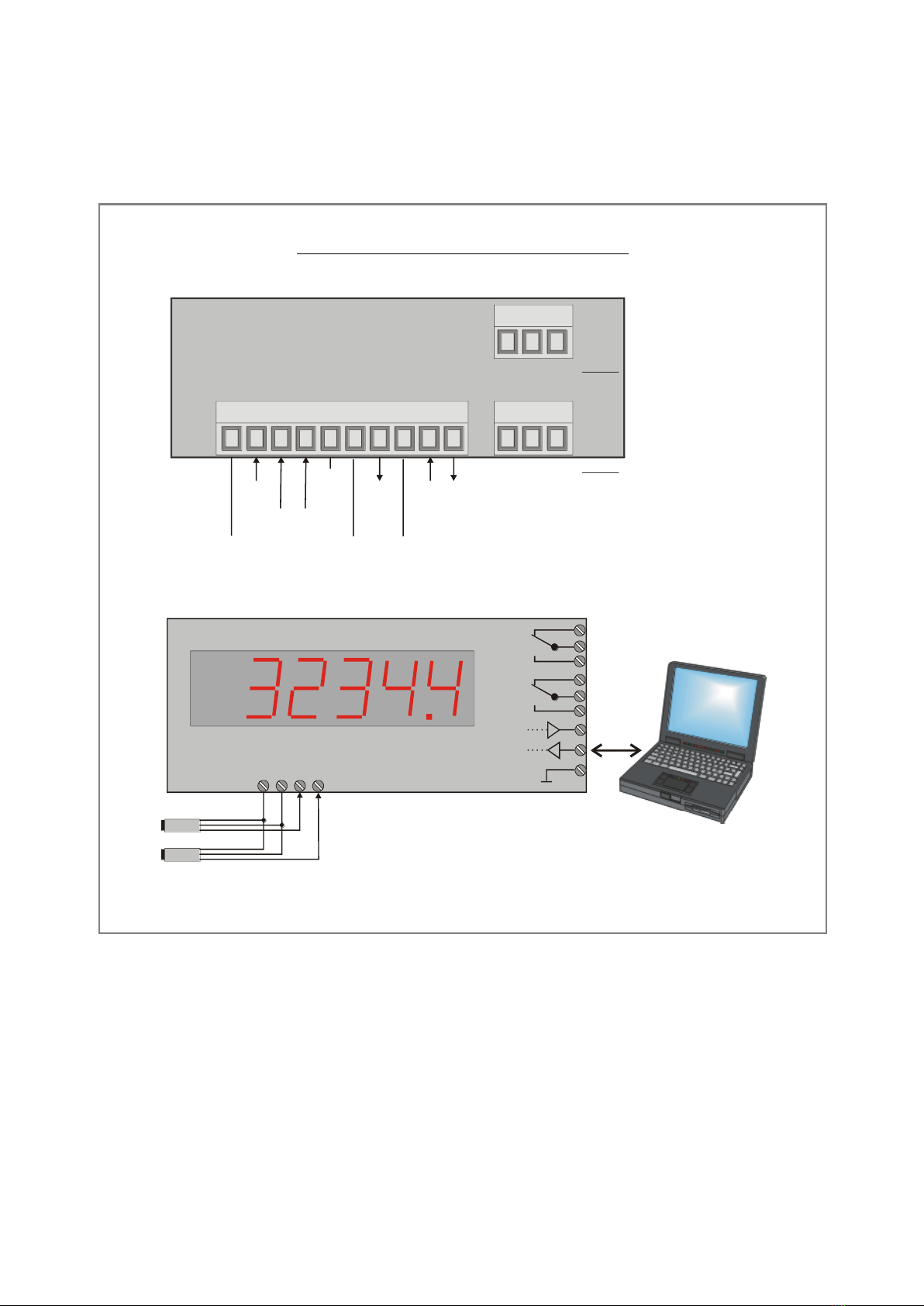

2. Electrical Connections..........................................................................................................................5

2.1. Power supply ................................................................................................................................6

2.2. Aux. voltage output ......................................................................................................................6

2.3. Analogue measuring inputs..........................................................................................................6

2.4. Relay Outputs ...............................................................................................................................6

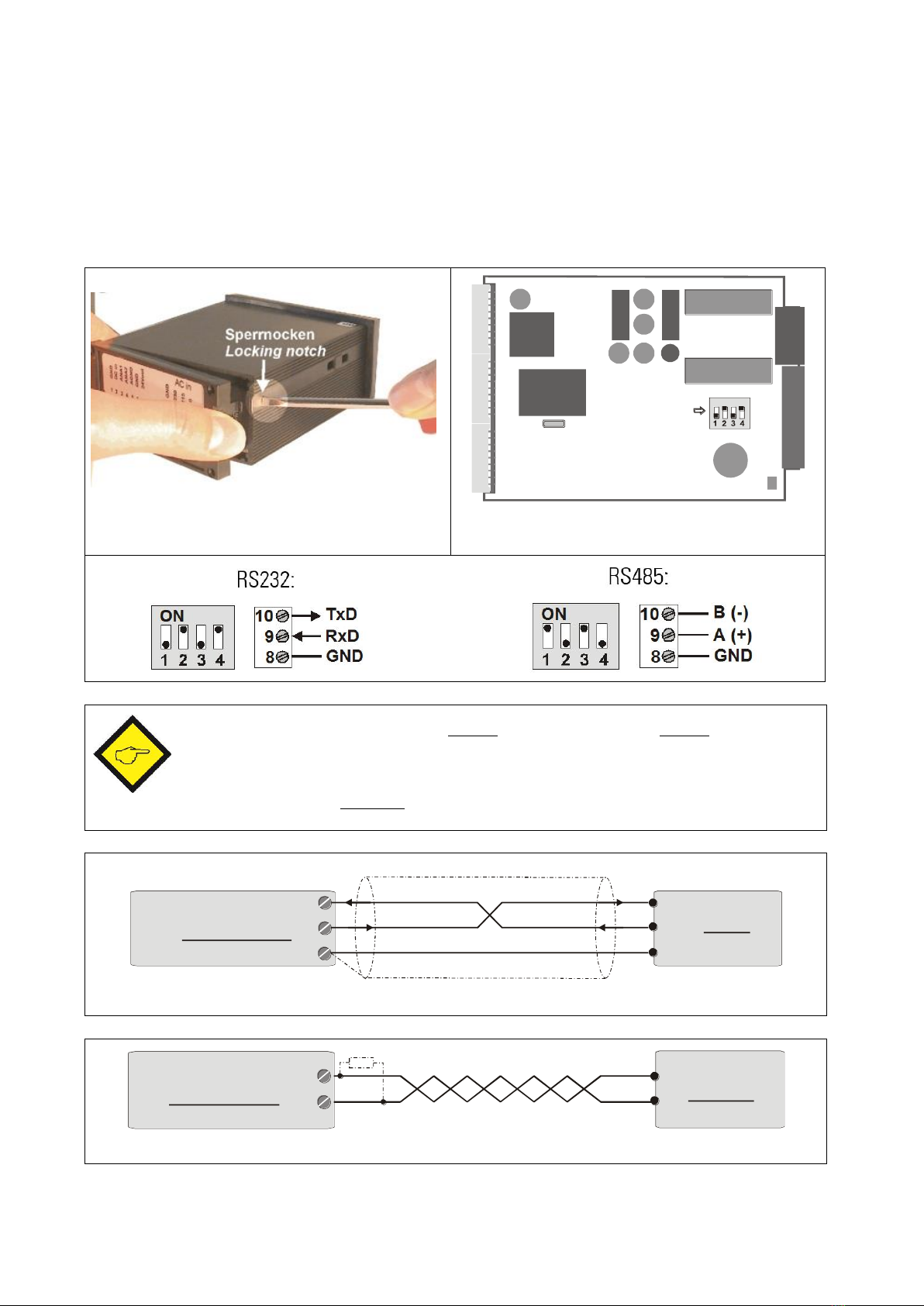

2.5. Serial RS232 / RS485 interface (AX 348 only).............................................................................7

3. Jumper settings ...................................................................................................................................8

4. How to Operate the Keys ...................................................................................................................10

4.1. Normal display state ..................................................................................................................10

4.2. Parameter settings .....................................................................................................................11

4.3. Teach operation..........................................................................................................................12

4.4. Set all parameters to “Default“ .................................................................................................12

4.5. Code Locking of the Keypad.......................................................................................................12

5. The Parameter Menu .........................................................................................................................13

5.1. Overview of Basic Parameters: ..................................................................................................13

5.2. Overview of Operational Parameters.........................................................................................14

6. Setting of Parameters ........................................................................................................................ 15

6.1. Basic Parameters........................................................................................................................15

6.2. Operational parameters..............................................................................................................16

6.3. Modes of operation ....................................................................................................................17

6.4. Additional settings for the Preselections and Relays................................................................20

6.5. Parameters for the Serial Interface............................................................................................23

7. Commissioning...................................................................................................................................27

8. Special Functions...............................................................................................................................28

8.1. Tare / Offset function .................................................................................................................28

8.2. Linearization ...............................................................................................................................28

8.3. Manual input or „Teaching“ of the interpolation points ...........................................................30

8.4. Overflow and Underflow Control ...............................................................................................32

9. Technical Appendix............................................................................................................................33

9.1. Parameter Lists...........................................................................................................................33

9.2. Dimensions .................................................................................................................................35

9.3. Technical data ............................................................................................................................36

9.4. Commissioning Form ..................................................................................................................37