6

5. Piglets and feeding

•Always ensure the nest is warm, >30°C.

•Ask your feed supplier for feed advice; always use a meal or a pellet with a maximum

diameter of 2mm.

•When switching to solid food this must be provided ad lib dry alongside the mash.

•The feed quantity is adjusted manually. In practice the trough must be empty for around

10 minutes in every hour. In this way leftover feed can be avoided.

•Manual adjustment demands little effort but does require discipline; it guarantees best

results.

•The sensor must only function as an emergency brake; under normal circumstances the

sensor does not come into contact with the feed.

•The best and simplest indication of the correct feed quantity is the absence of old leftover

feed in the trough. The feed in the trough must look fresh!

•Too much feed: there is old leftover feed.

•Too little feed: the piglets are hungry and the trough is empty.

•Checking once a day is sufficient; the best time to check is in the afternoon.

•The feed should not be too runny or too dry, it should flow to some extent (dry content 20-

24%).

•If diarrhoea should occur, immediately provide water with organic acids and select a feed

type with a lower energy content.

•Provide drinking water freely as soon as the piglets are familiar with the mash.

•Avoid age differences as far as possible.

6. Cleaning and maintenance

•The trough can be hosed clean.

•Through the slot in the hull you can reach the outlet of the mixing chamber with water.

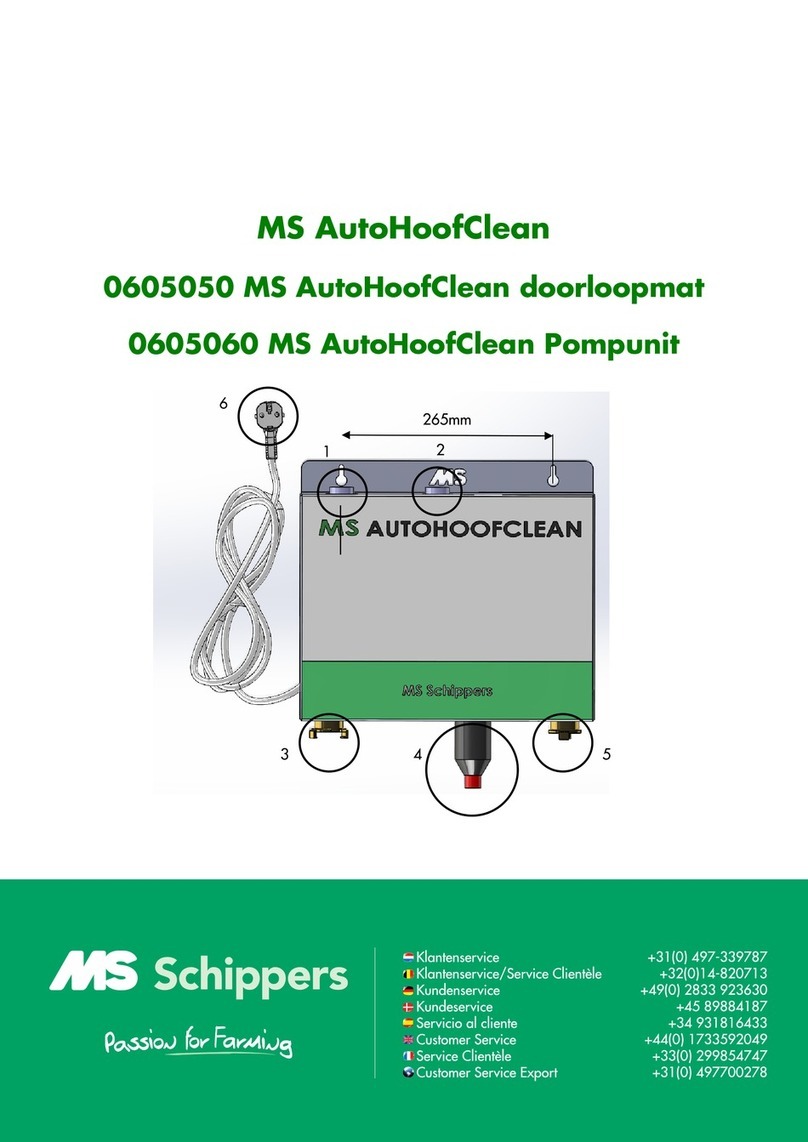

•Mixing springs and futher technics can be reached by removing the hull, photo 6.

•Never use a high-pressure spray when hull is removed.

•The inside of the feed hopper only holds dry feed and does not have to be wet-cleaned.

•The machine requires no specific maintenance other than the compulsory safety

inspections.

7. Guarantee

•The guarantee period runs for one year.