Contents

1.0 Introduction ............................................................................1

1.1 Safety Section ....................................................................... 2

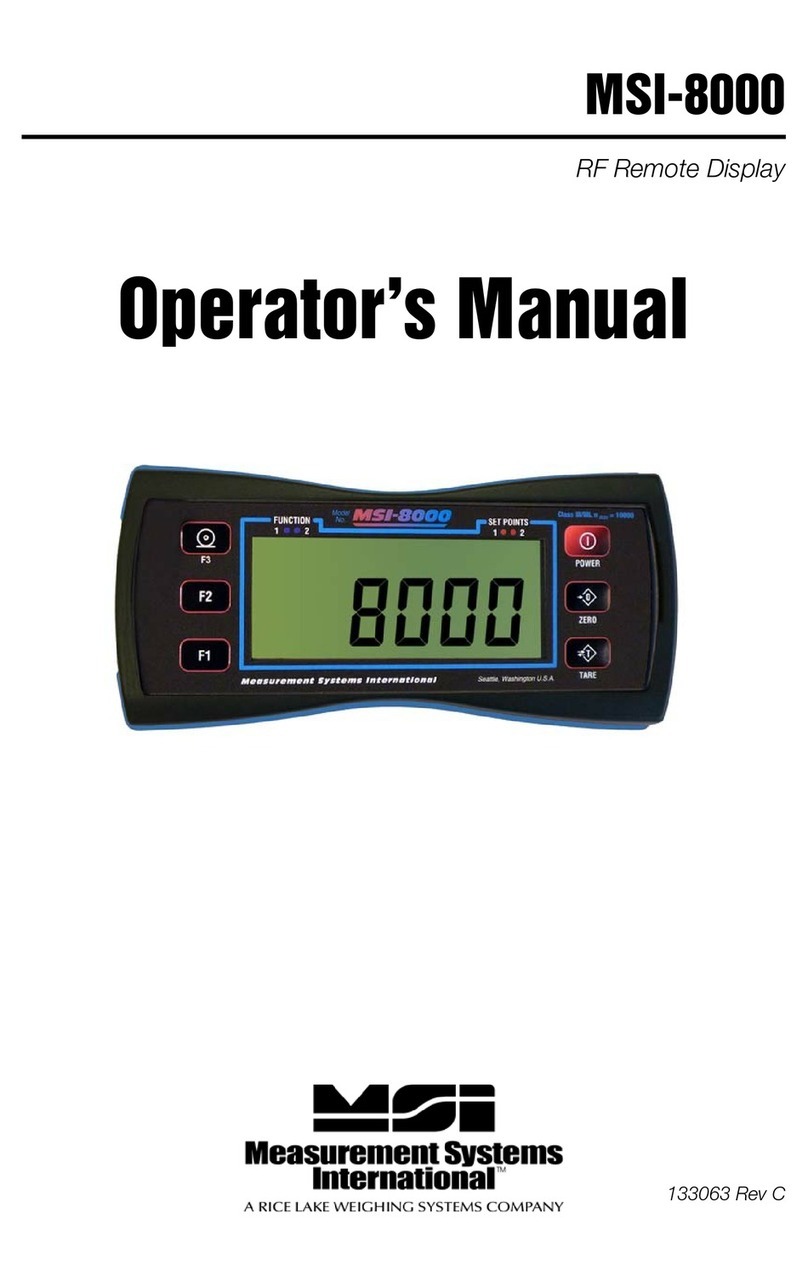

1.2 Front Panel Descriptions ..................................................... 3

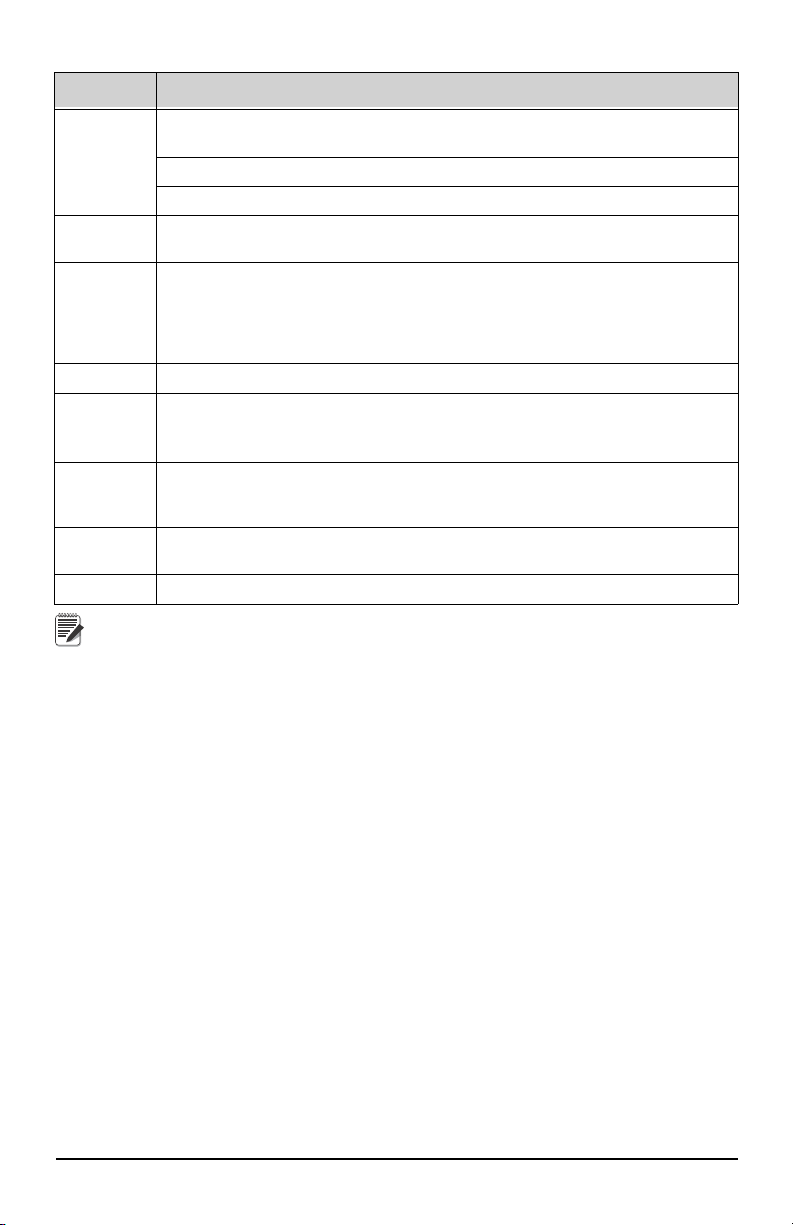

1.3 Specifications ....................................................................... 5

1.4 Features ................................................................................ 6

1.5 FCC Statement ..................................................................... 6

1.6 International RF Certs .......................................................... 6

1.7 Getting Started ..................................................................... 7

1.8 Options .................................................................................. 7

1.9 Unpacking ............................................................................. 8

2.0 Operation ................................................................................9

2.1 Power .................................................................................... 9

2.2 Zero ....................................................................................... 9

2.3 Tare ..................................................................................... 10

3.0 User Defined Function Keys .................................................11

3.1 Off ........................................................................................ 11

3.2 Test ...................................................................................... 11

3.3 Total .................................................................................... 11

3.3.1 Manual Total ...........................................................................12

3.3.2 Auto Total ...............................................................................12

3.3.3 View Total ...............................................................................12

3.4 Net/Gross ............................................................................ 12

3.5 Peak Hold ............................................................................ 13

3.5.1 Capture Peak Force ................................................................13

3.6 2-Units/ 5-Units .................................................................. 14

3.7 Hi-Res ................................................................................. 14

3.8 Print ..................................................................................... 14

3.9 Scan .................................................................................... 14

3.10 Total Remote Devices ........................................................ 15

3.11 Tare ..................................................................................... 15

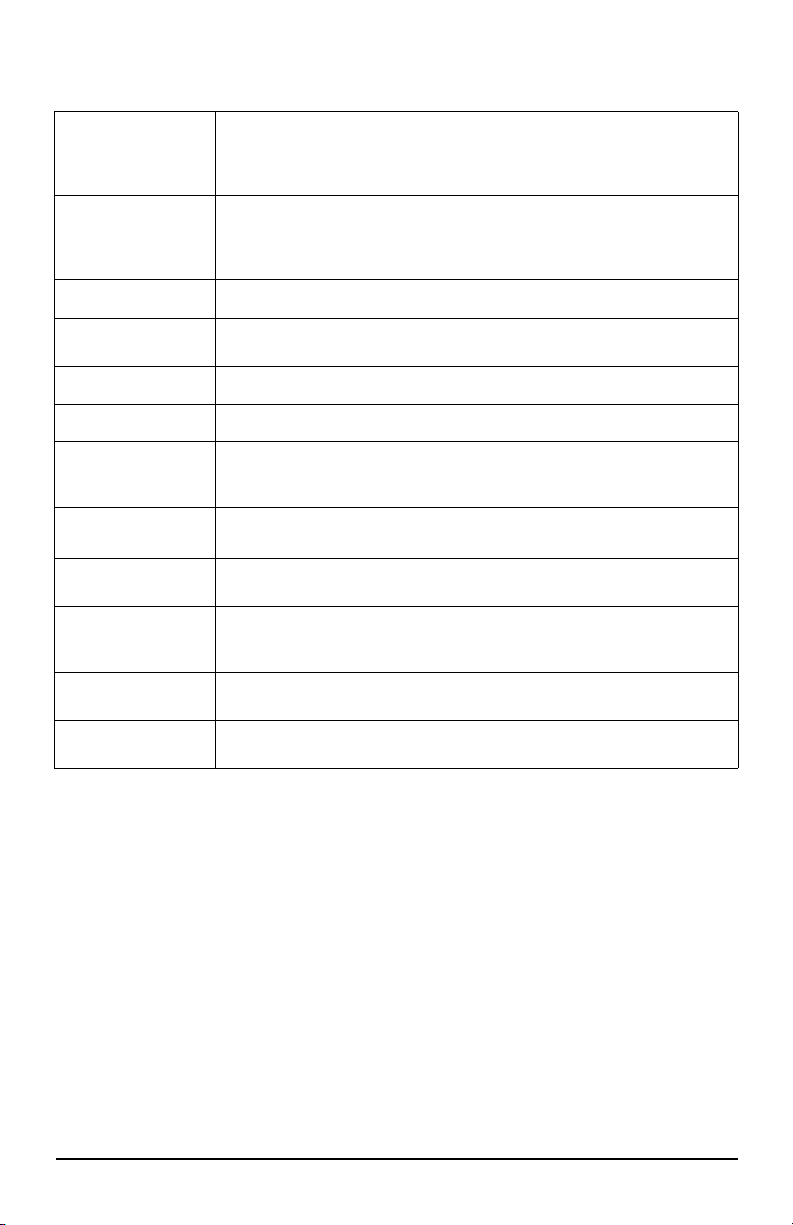

4.0 Set Up ...................................................................................16

4.1 Menu Map ........................................................................... 16

4.2 Function Keys ..................................................................... 17

4.3 Auto-Off ............................................................................... 18

5.0 COMM Set Up .......................................................................19

Technical training seminars are available through Rice Lake Weighing Systems.

Course descriptions and dates can be viewed at www.ricelake.com/training

or obtained by calling 715-234-9171 and asking for the training department.

© Rice Lake Weighing Systems. All rights reserved. Printed in the United States of America.

Specifications subject to change without notice.

Rice Lake Weighing Systems is an ISO 9001 registered company.

November 25, 2013